1

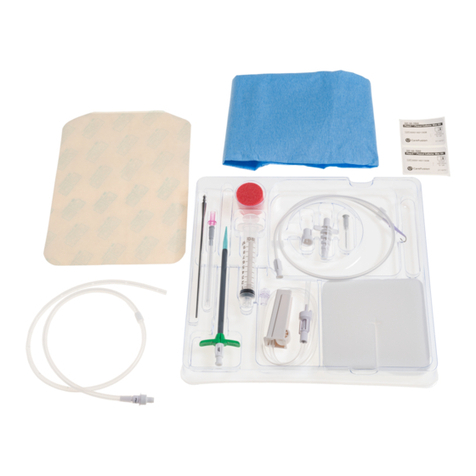

Container Components

(A) Sterilant Access Holes

(B) Lid Latch

(C ) Carrying Handle

(D) Bottom Latch

(E) Container Identification Tag

(F) Data Block

(G) Sled Groove

(H) Filter Retention Plate

(I) Cam Lever

(J) Alignment Tabs

(K) Filter

() Optional Protective Plate

(M) Gasket & Retaining Groove

(N) Filter Ridge

(O) Sled Feet

Instructions for Use

These instructions provide information on how to set up, use, troubleshoot, and

maintain the Genesis reusable rigid sterilization container system. It does not cover

service and repair procedures. For information about the product that is not covered

in this document, contact your local distributor or send an email request to GMB-

Intended Use

The Genesis reusable rigid sterilization container system is a device intended to be

used to enclose another medical device that is to be sterilized by a healthcare

provider. It allows sterilization of the enclosed medical device and maintains sterility

of the enclosed device until used. Figure 1

Baskets and accessory items are intended to organize and secure enclosed medical

devices during sterilization, transport, and storage of the container.

Note: For detailed information regarding usage of specific containers, accessories,

materials, weight limits, and supported sterilization challenges for indicated

sterilization modalities, refer to the Modality Specific Recommendations for

Accessories and Containers chart.

Initial Receiving

Inspect, thoroughly clean, and rinse all reusable components (container, basket, and

accessories) before placing into service. Not properly preparing your Genesis

sterilization containers may adversely affect the protective anodized finish.

General Precautions

Cleaning

• Use only properly diluted, enzymatic / neutral pH detergent solution

recommended for safe use on anodized aluminum. Use of highly acidic or highly

alkaline detergents could permanently damage the protective finish of the

container.

• Alcohol is not recommended for manual cleaning or wiping down. All cleaning

agents should be thoroughly rinsed off prior to any sterilization process to

remove all residual chemicals which could damage the protective anodized finish.

• Do not use abrasive cleaners, abrasive cleaning pads, or metal brushes on

container surfaces. Use of these abrasive materials will permanently damage the

protective anodized finish of the container.

• Do not clean the anodized container or container components (bottom, lid,

retention plate, optional protective plate) in an ultrasonic washer.

• Ultrasonic cleaning (cavitation) processes may loosen threaded accessories such

as pins, dividers, etc. Routine inspection of threaded accessories may require

tightening to secure them after ultrasonic processing.

Processing

• Do not obstruct the sterilant access holes. These holes allow the exchange of air

and penetration of sterilant into and out of the container. When these access

holes are blocked, it can impede this exchange process. Under pre-vacuum

steam, this blockage can cause the container to collapse.

• Do not use adhesive tape on the container.

• The use of basket liners may cause condensate to pool.

• The DST Series Filter recommended for use with Genesis reusable rigid

sterilization containers is for single use only. One filter sheet, or thickness, should

be used underneath each retention plate per process. Using more than one

thickness of the recommended filter (DST Series) has not been validated for

efficacy. ach sterilant access (perforated) area requires one filter.

• When sterilizing mixed loads, containers must be placed below absorbent,

wrapped items on the autoclave cart to avoid excess condensation dripping onto

wrapped goods below the container.

• Sterilize container and contents using hospital protocol. Since sterilizers vary in

design and performance characteristics, it is strongly recommended that the user

verify the cycle parameters for the specific sterilizer and types of instruments

being sterilized prior to use.

• Always practice safe lifting and handling of heavy objects. Do not stack containers

more than three (3) high in pre-vacuum sterilization cycles, per recommended

dry time parameters. Stacking is only recommended in pre-vacuum steam cycles.

• Be sure to choose the correct data card material for the sterilization process used.

Cellulose materials are compatible with steam and thylene Oxide ( O)

processes. Cellulose materials are not compatible with the ST RRAD 50 or

ST RRAD 100S processes.

Steam and 100% O: MD1-1 cellulose data card.

ST RRAD 50 and 100S: MH1-1 non-cellulose data card.

• It is important that each facility verify the manufacturer's written sterilization

instructions (Instructions for Use) to verify that the conditions in their particular

facility (i.e. steam quality, equipment, protocols) achieve the same results as the

manufacturer. If not, the container manufacturer, as well as the equipment

manufacturer, should be consulted to identify potential causes and remedies.

• Only Genesis filters, arrows, data cards, baskets, accessories, and repair parts are

validated for use with the Genesis reusable rigid sterilization container system. Do

not use unauthorized single use accessories or container components.

• If using pre-vacuum steam immediate use steam sterilization (IUSS), container

contents will be wet upon removal from the sterilizer.

Warnings

• Do not use filter materials in the presence of flammable anesthesia. A safety

hazard may occur.

Cautions

• Complex instruments, such as air powered instruments, endoscopes or

instruments with lumens or channels should be sterilized according to the

instrument manufacturer's instructions.

• Lumen devices have not been validated for use in gravity-displacement steam

sterilization modalities.

• Only the following lumen devices have been validated for use in the pre-vacuum

steam modalities:

• ≥ 2.68 mm in inner diameter and ≤ 450 mm in length

• ≥ 1.37 mm in inner diameter and ≤ 242 mm in length

• Lumen devices exceeding 400 mm in length or less than 3.0 mm in inner

diameter have not been validated for use in the 100% thylene Oxide,

ST RRAD 50, or ST RRAD 100S modalities.

• Devices containing silicone and polymeric materials (including silicone mats and

bars) have not been validated for use in gravity-displacement steam sterilization

modalities.

• The stacking basket configuration has not been validated for use in gravity-

displacement steam or 100% thylene Oxide modalities.

• A basket or lifting platform must always be used when sterilizing in a perforated

bottom container model.

• The optional protective plate has not been validated for use in gravity

displacement steam, 100% thylene Oxide, ST RRAD 50, or ST RRAD 100S

modalities.

• Solid bottom containers have not been validated for use in gravity-displacement

steam or 100% thylene Oxide modalities.

• Containers have not been validated for stacking in gravity-displacement steam,

ST RRAD 50, ST RRAD 100S, or 100% thylene Oxide modalities.

• Silicone mat devices have not been validated for use in 100% thylene Oxide,

ST RRAD 50 or ST RRAD 100S modalities.

• Container models other than the Genesis ST RRAD model containers have not

been validated for use in the ST RRAD 50 or ST RRAD 100S modalities.

• Perforated container model numbers CD2-10BDL and DINCD2-8B are not

validated for use in the 100% thylene Oxide Sterilization modality.

• Filter materials other than the Genesis DST-series filters have not been validated

for use with the Genesis sterilization containers.

• The optional protective plate has not been validated for use in the Genesis

container bottom.

• Devices entailing surfaces that are completely obstructed (air-tight occluded

challenges) have not been validated for use with the Genesis reusable rigid

sterilization container system.

Proofed by: ____________________________ Date: _____________

Dimensions checked: ______________ Copy checked: _____________

CF36-1375D

06-23-16

David Knuth

en