10 P/N: 10001681 (REV AF) August 2020

Failure to properly ground the hoist presents the danger of

electric shock.

TO AVOID INJURY:

Permanently ground the hoist as instructed in this manual.

Operate hoist over the entire length of its rated lift, checking upper

and lower limit switches for correct operation as follows:

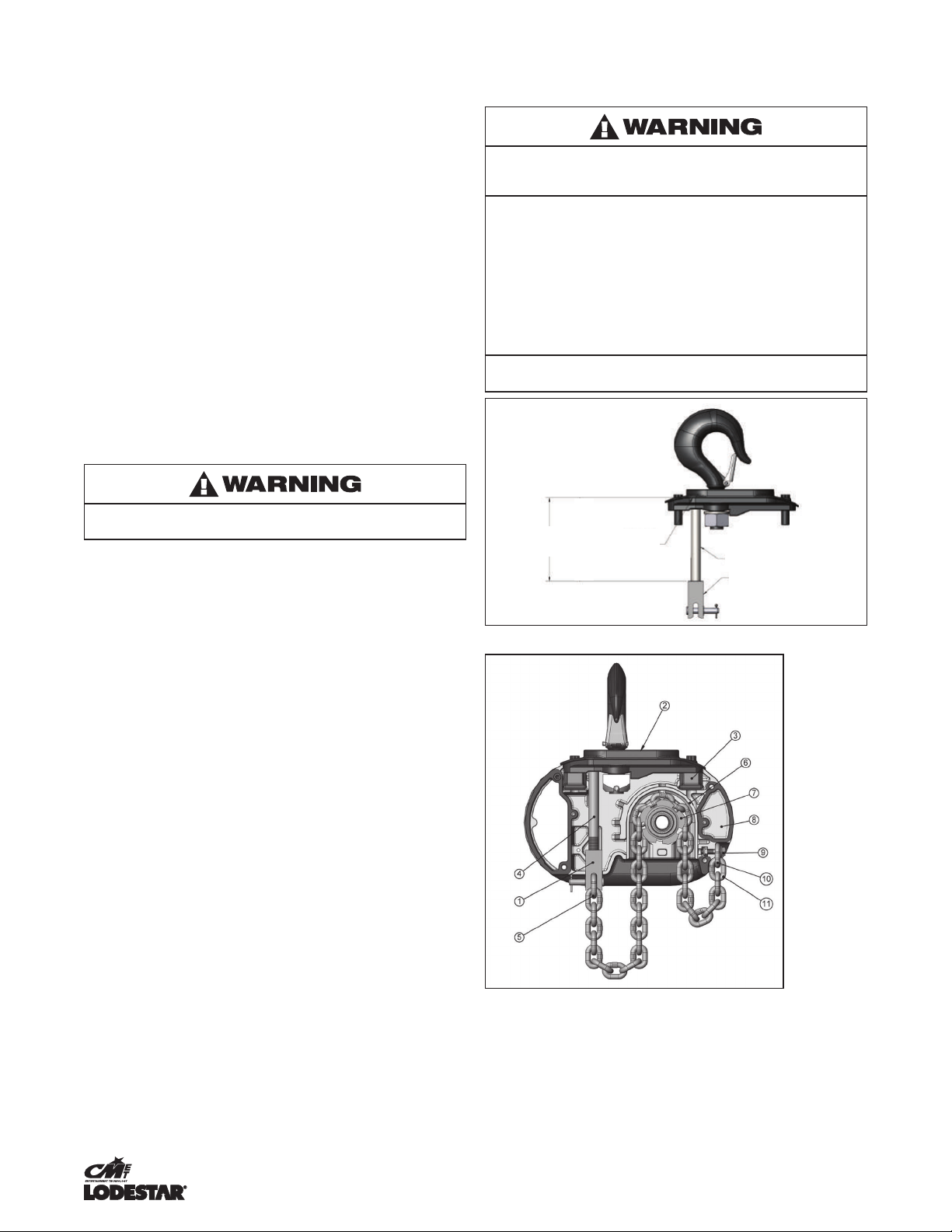

1. Press (UP) control and raise the lower hook until top of hook

block is about 12 inches (305 mm) below the hoist.

2. Cautiously continue raising the hook until the upper limit

switch stops the upward motion. The upper limit switch is

set at the factory to stop the hook block 8 links from the

bottom of all hoists.

3. If adjustment is necessary, see page 15.

4. Press(DOWN) control and cautiously lower hook until lower limit

switch stops the downward motion. On hoist operated in the

motor down orientation, maintain a minimum of 24" (610mm) of

chain freely hanging over the side of the hoist.

5. If adjustment is necessary, see page 15.

NOTE: If the hoist is equipped with a chain container/bag,

reset the upper and lower limit switches as indicated on

page 15.

Under no condition should the hook block or load be

permitted to come in contact with the chain container/bag.

If contact is made, the function of the chain container can

be interfered with and its fasteners imperiled.

NOTE: When chain bag is filled to capacity the bag must be

no more than 75% filled.

OPERATING INSTRUCTIONS

GENERAL

1. The Load-limiter is designed to slip on an excessive overload.

An overload is indicated when the hoist will not raise the load.

Also, some clutching noise may be heard if the hoist is loaded

beyond rated capacity. Should this occur, immediately release

the £(UP) control to stop the operation of the hoist. At this

point, the load should be reduced to the rated hoist capacity

or the hoist should be replaced with one of the proper capacity.

When the excessive load is removed, normal hoist operation is

automatically restored.

CAUTION: The Load-limiter is susceptible to overheating

and wear when slipped for extended periods. Under no

circumstance should the clutch be allowed to slip for more

than a few seconds.

Due to the above, a hoist equipped with a Load-limiter is not

recommended for use in any application where there is a possibility

of adding to an already suspended load to the point of overload.

This includes dumbwaiter installations, containers that are loaded

in mid-air, etc.

HOIST

1. Before picking up a load, check to see that the hoist is

directly overhead.

2. WHEN APPLYING A LOAD, IT SHOULD BE DIRECTLY UNDER

HOIST OR TROLLEY. AVOID OFF CENTER LOADING OF

ANY KIND.

3. Take up a slack load chain carefully and start load easily to

avoid shock and jerking of hoist load chain. If there is any

evidence of overloading, immediately lower the load and

remove the excess load.

4. DO NOT allow the load to swing or twist while hoisting.

5. DO NOT allow the load to bear against the hook latch.

SAFE OPERATING INSTRUCTIONS

AND PROCEDURES

For safety precautions and a list of Do’s and Do Not’s for safe

operation of hoists, refer to page 3.

1. Permit only competent personnel to operate unit.

2. When preparing to lift a load, be sure that the attachments

to the hook are rmly seated in hook saddle. Avoid off center

loading of any kind, especially loading on the point of hook.

3. Do not allow the load to bear against the hook latch. The latch

is to help maintain the hook in position while the chain is slack

before taking up slack chain.

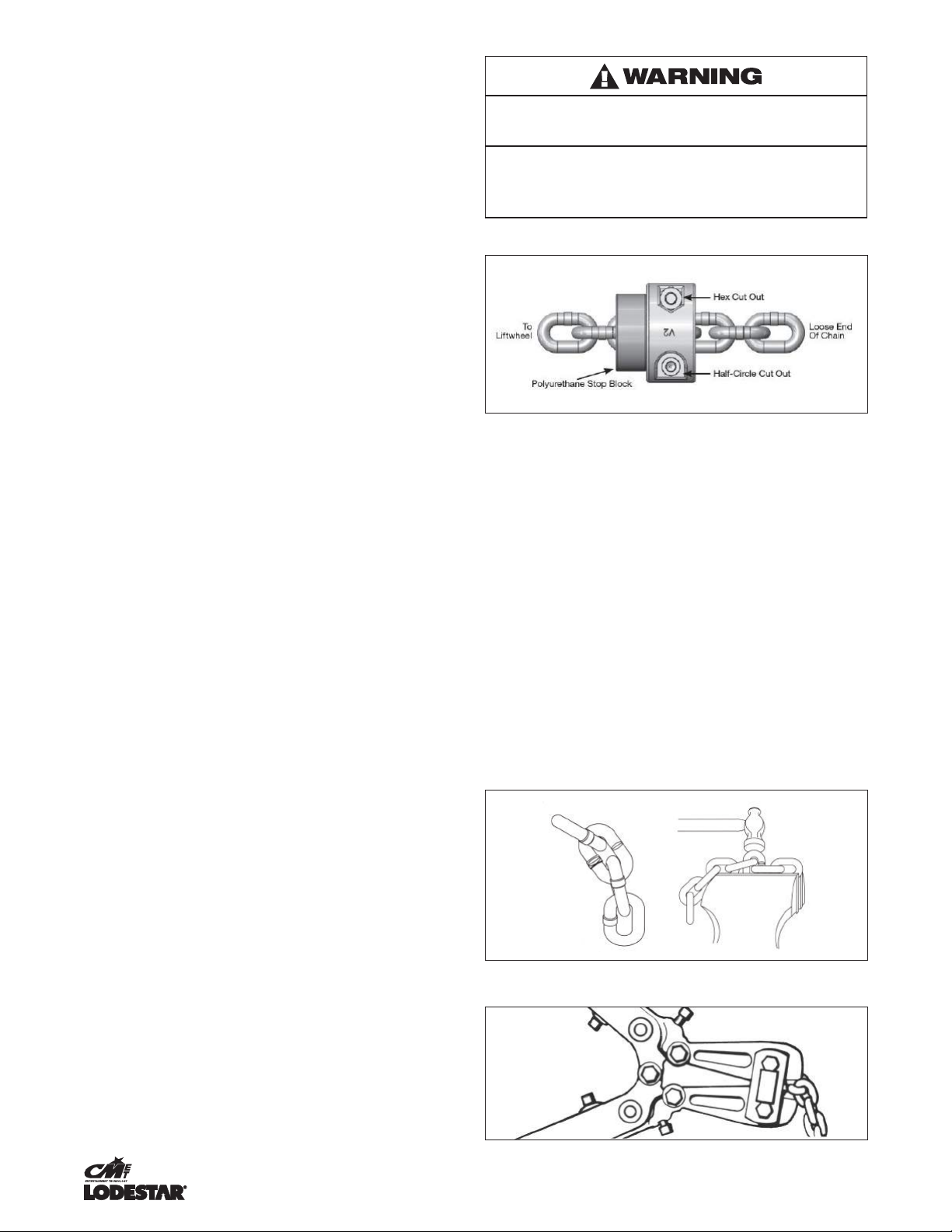

4. Do not wrap the load chain around the load and hook onto itself

as a choker chain. Doing this will result in:

a. The loss of the swivel effect of the hook which could

result in twisted chain and a jammed lift wheel.

b. The upper limit switch, if so equipped, is bypassed

and the load could hit the hoist.

c. The chain could be damaged at the hook.

5. Before lifting load, check for twists in the load chain.

On double reeved units A twist can occur if the lower

hook block has been capsized between the strands

of chain. Reverse the capsize to remove twist.

6. On single reeved chain hoist used in conjunction with

head blocks and ground support systems, check for twists

between the hoist and head block. Twisted load can result

in a jammed liftwheel.

7. Do not use this or any other overhead materials handling

equipment for lifting persons.

8. Do not load hoist beyond the rated capacity shown on hoist

identication plate or on the hoist motor housing cover or hoist

back frame cover. Overload can cause immediate failure of

some load-carrying part or create a defect causing subsequent

failure at less than rated capacity. When in doubt, use the next

larger capacity CM Lodestar Hoist.

9. Warn personnel of your intention to lift a load in the area.

Tie off the load with auxiliary chains or cables before access

to the area beneath the load is permitted.

10. Do not operate hoist at unusual extremes of ambient

temperatures above 150º F (60º C) or below 0º F (-17º C).

STAGE OPERATION

Hoists can be removed from the road case by manual lifting,

or rigged while still in the case and power out.

Manual Lifting – It is recommended that two people be used to the

lift the hoist from the road case. The hoist can be lifted by grasping

the handles (if tted), the end covers, or the load chain. Never pull on

the electrical cable(s) even if equipped with an external strain relief.

When placed on the oor the hoist should be positioned on its side

with the chain pulled away to allow the chain to enter the hoist

without jamming if the hoist is to be operated.

Never operate a Lodestar hoist

while standing on its end as in the

gure to the right.

The hoist may tip over and damage

the casing, but more importantly it

will cause the Lodestar to “drag”

against its brake putting extra strain

on the electric motor.

When running chain “in” the hoist should be laid on its side on the

ground / stage with the chain stretched out along the ground. The

“dead” end side of the hoist should be on the oor. With the hoist