ENGLISH

6

(ENGLISH) P/N 192048551 Rev. AA (January 2018)

GENERAL INFORMATION

The CM® Hurricane 360 hand operated chain hoist has been

expanded to include trolley suspended units. The CM Hurricane

IPR/IPG Integrated Trolley Hoist consists of the lightweight,

durable Hurricane 360 Hand Hoist rigidly suspended from a four

wheel trolley. To suspend the hoist from the trolley, the upper hook

is replaced by a pair of load bars. All other components of the

hoist including the lower hook parts are shown and described in

Hurricane 360 Hoist manual (P/N 656).

In addition to the Hurricane IPR/IPG Integrated Trolley manual

(P/N 192048551), please review the hoist manual (P/N 192048547)

for operating instructions, safety procedures, inspections and

maintenance procedures, lubrication information, troubleshooting,

hoist exploded view, parts list and load chain reeving information.

Hoists with integrated trolleys with load ratings of 1/2, 1, 2, 3,

5, 10 and 20 metric ton are available and this manual applies to

all of these units. Standard lifts are 10, 15, 20, and 30 feet and

hoists with longer lifts are available on a special, per order basis.

Zinc-plated steel hand chain is provided with a drop that is 2 feet

less than the lift of the hoist.

CM®Hurricane IPR/IPG Integrated Trolley Hoists are built in

accordance with the specications contained herein and at the time

of manufacture complies with our interpretation of the American

Society of Mechanical Engineers (ASME) Standard B30.16,

“Overhead Hoists.” Copies of this standard can be obtained from

ASME Order Department, 22 Law Drive, Box 2300, Faireld, NJ

07007-2300, USA.

This manual contains important information to help you properly

install, operate and maintain your CM®Hurricane IPR/IPG Integrated

Trolley Hoists for maximum performance, economy and safety.

Please study its contents thoroughly before putting your

Integrated Trolley Hoists into operation. By practicing correct

operating procedures and by carrying out the recommended

preventive maintenance suggestions, you will be assured of

long, dependable and safe service.

After you have completely familiarized yourself with the

contents of this manual, we recommend that you carefully

le it for future reference.

REPAIR/REPLACEMENT POLICY

All Columbus McKinnon (CM®) Hurricane IPR/IPG Integrated Trolley

Hoists are inspected and performance tested prior to shipment.

If any properly maintained hoist develops a performance problem,

within one one year of shipment, due to a material or workmanship

defect, as veried by CM, repair or replacement of the unit will

be made to the original purchaser without charge. This repair/

replacement policy applies only to CM®Hurricane IPR/IPG

Integrated Trolley Hoists installed, maintained and operated

as outlined in this manual, and specically excludes hoists

subject to normal wear, abuse, improper installation, improper

or inadequate maintenance, hostile environmental effects and

unauthorized repairs/modications.

We reserve the right to change materials or design if, in our

opinion, such changes will improve our product. Abuse, repair

by an unauthorized person, or use of non-CM® replacement parts

voids the guarantee and could lead to dangerous operation. For

full Terms of Sale, see Sales Order Acknowledgement. Also, refer

to the back cover for Limitations of Warranties, Remedies and

Damages, and Indemnication and Safe Operation.

UNPACKING

After opening the carton, the integrated trolley hoist should be

carefully inspected for damage which may have occurred during

shipment or handling. Check the hoist frame for dents or cracks

and inspect the load chain for nicks and gouges. If shipping

damage has occurred, refer to the packing list envelope on

the carton for claim procedure.

Operating a unit with obvious external damage may cause

load to drop and that may result in personal injury and/or

property damage.

TO AVOID INJURY:

Carefully check unit for external damage prior to installation.

INSTALLATION

Before installing the hoist:

1. Determine the weight of the load that is to be lifted or moved

and make sure it does not exceed the rated load of the hoist.

2. Make sure the support or beam to which the trolley is attached

is strong enough to hold several times the weight of the load to

be lifted or moved. Be sure the integrated trolley hoist is solidly

held on the beam.

Attaching the hoist to an inadequate support may allow the hoist

and load to fall and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the structure has sufcient strength to hold several

times the hoist and its rated load.

3. The area in which the hoist is installed must provide sufcient

room for:

– The operator to operate the hand chain.

– The operator and other personnel to stand clear of the load

at all times.

– Firm footing for the operator.

– Clearance between the hoist frame and any object.

– The frame to be free to swivel on the upper hook.

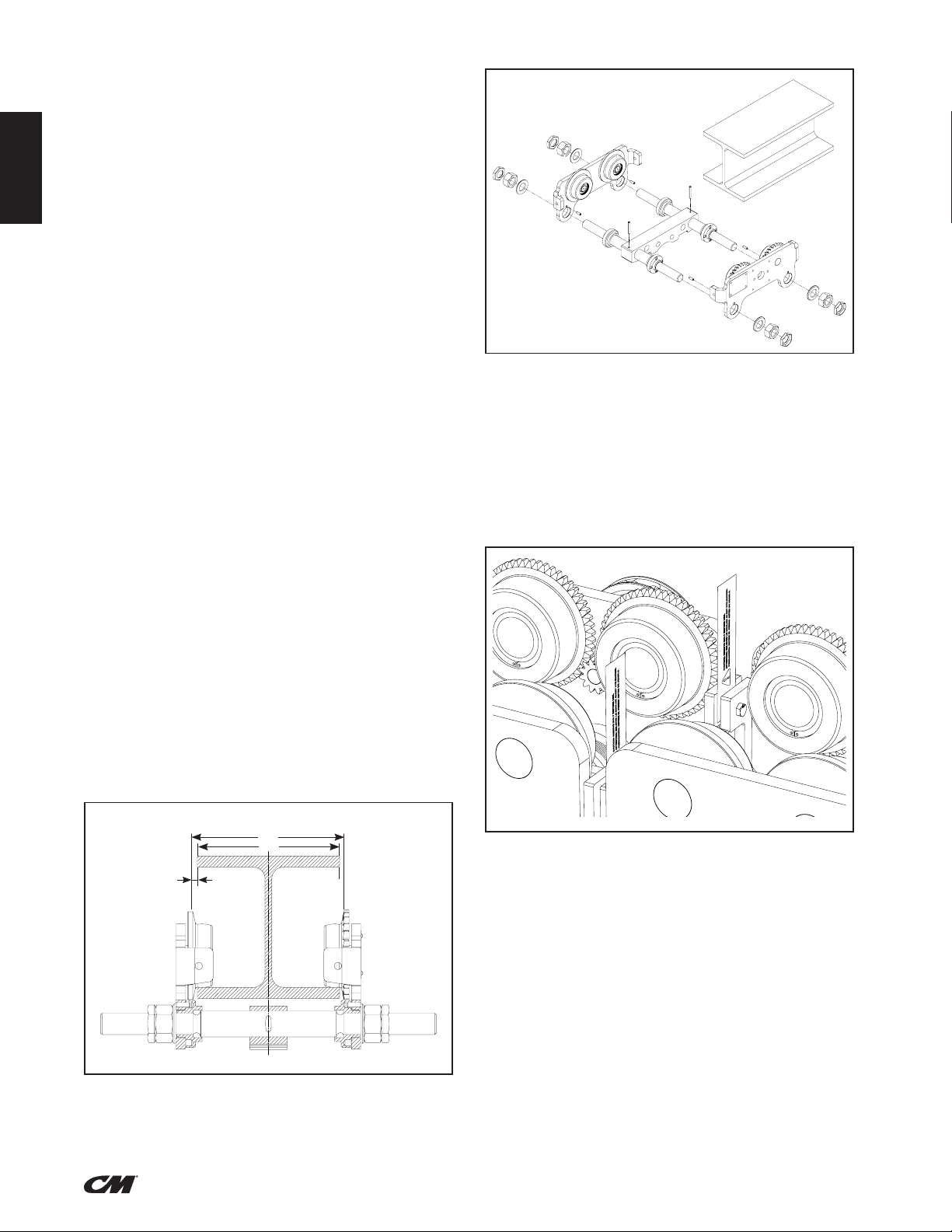

BEFORE INSTALLING THE TROLLEY:

Operating the trolley hoist on a beam that has no rail stops may

allow the trolley hoist to fall off the end of the beam.

TO AVOID INJURY:

Install rail stops at each end of the beam on which the trolley hoist

is to operate.

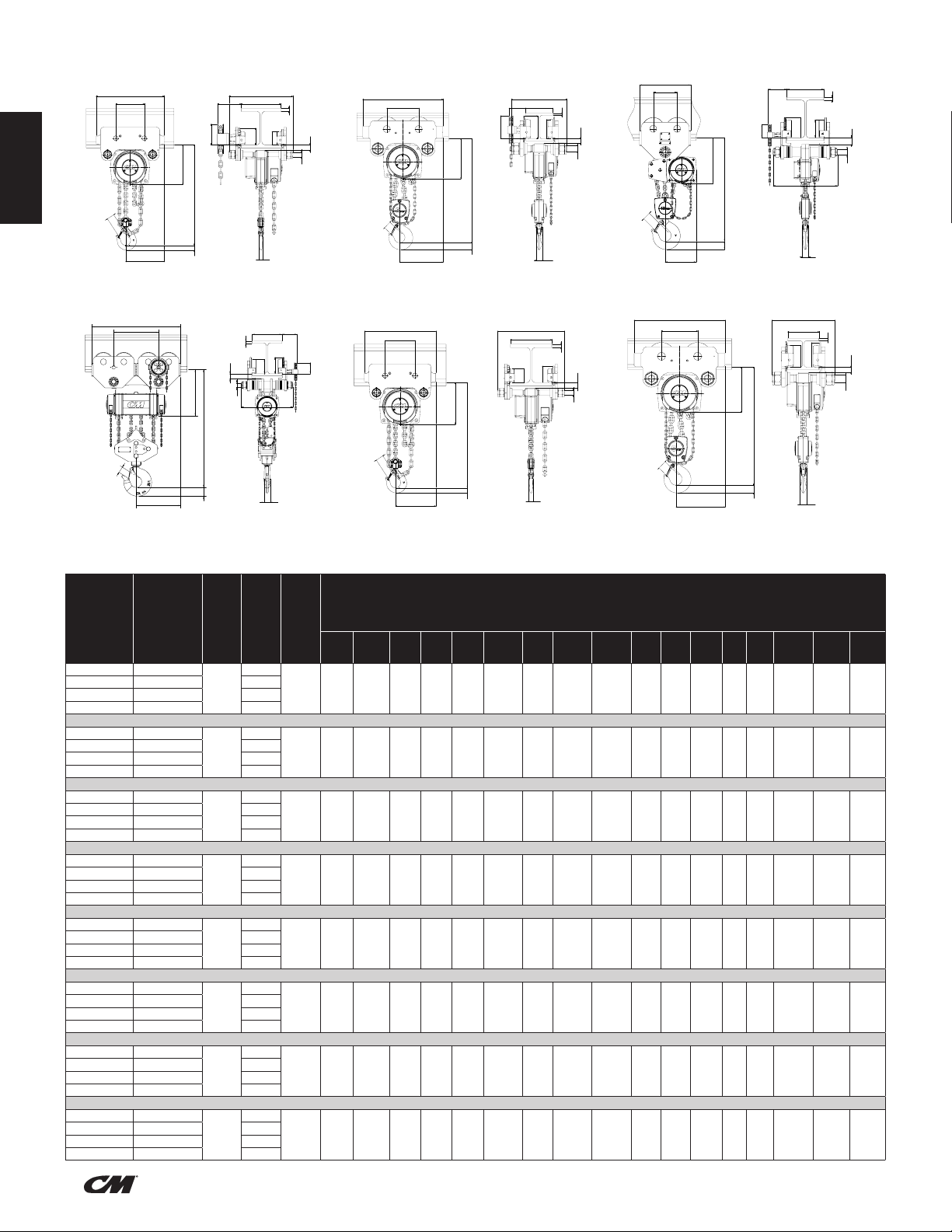

The railstops must be positioned so as to not exert impact force

on the hoist portion of the unit or the trolley wheels. They must

contact the ends of the trolley side frames. Due to the variations

in beam ange widths, it is suggested that the beam ange width

be measured to determine the necessary trolley ange width

adjustment. The distance between trackwheel anges (dimension

“X”) should be 1/8 to 3/16 inch greater than the beam ange width

for straight runway beams, and 3/16 to 1/4 inch greater than the

beam ange width if runway system includes sharp curves.

INSPECTION OF THE ATTACHMENT POINT

The attachment point for the hoist must be selected so that the

supporting structure to which it is to be tted has sufcient stability

and to ensure that the expected forces can be safely absorbed. The

unit must align freely also under load in order to avoid impermissible

additional loading. The selection and calculation of the appropriate

supporting structure are the responsibility of the operating company.

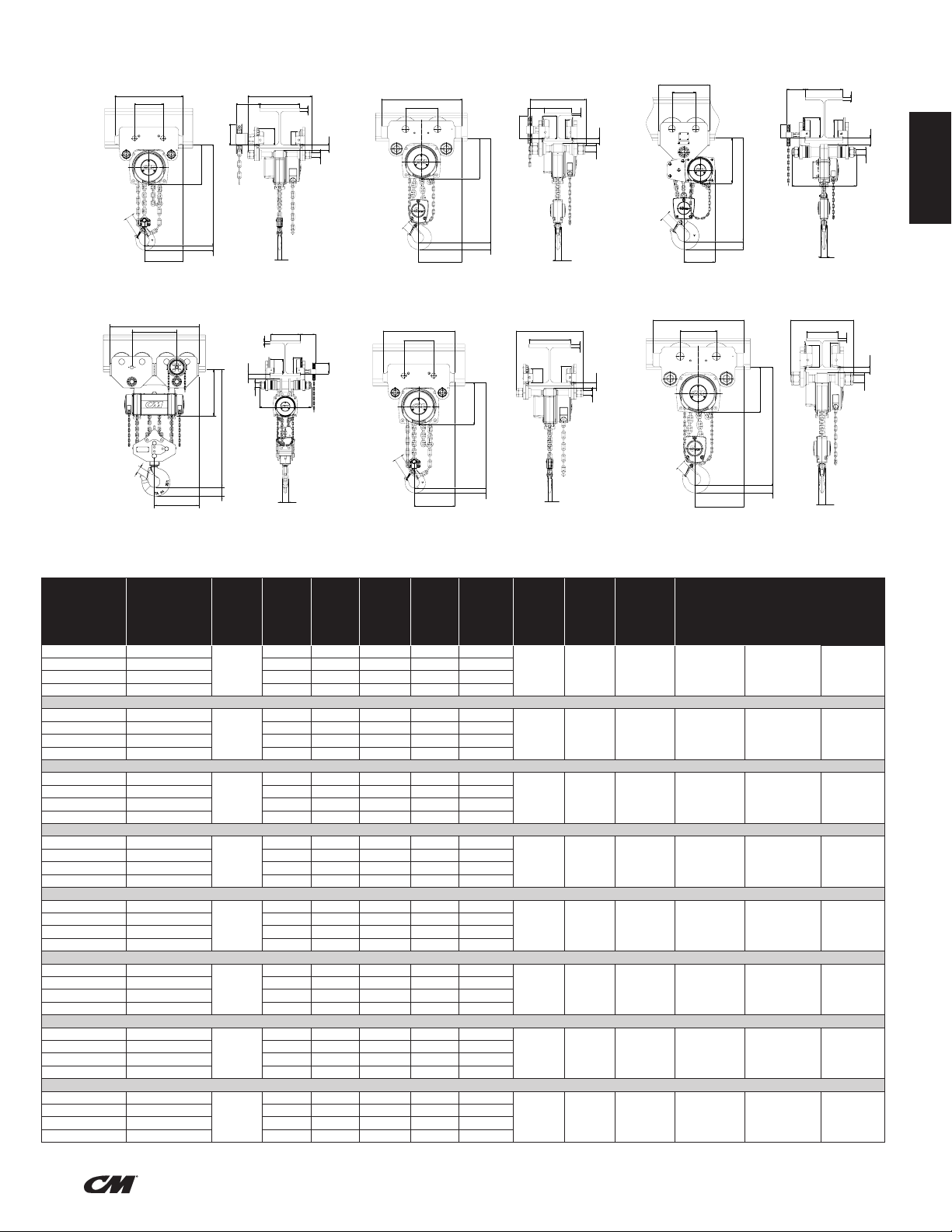

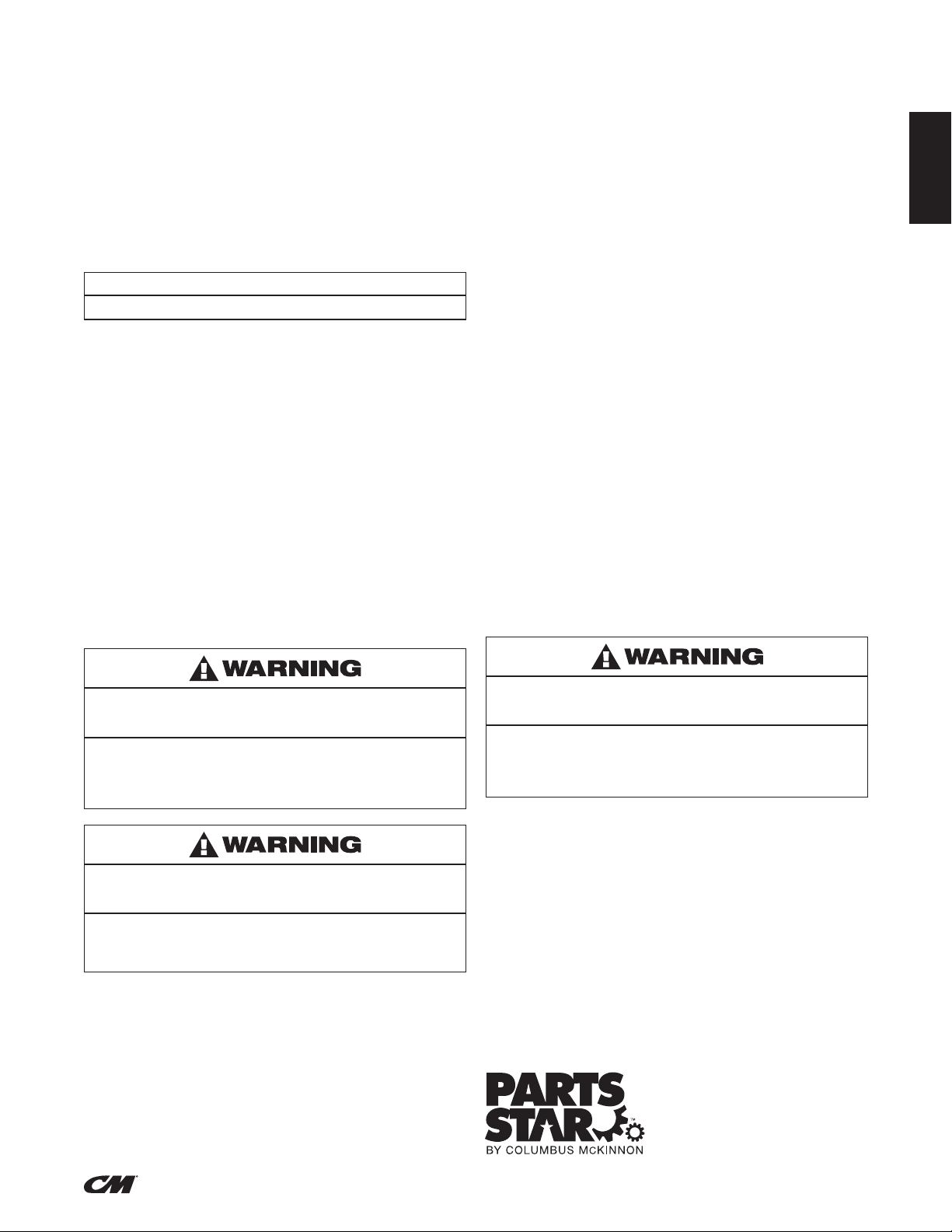

INSTALLING THE TROLLEY UP TO 5 TONNES

(5000 KG)

The trolleys are built to t beam range A or B which is indicated

on the identity plate. Before installation, make sure that the track

beam width is within this beam range. The further procedure for

assembly of the unit on the track beams depends on whether the

track beam has an accessible open end or not. If the beam has an

open end, it is recommended that the unit be preassembled on the

ground and then be pushed onto the open end of the beam.