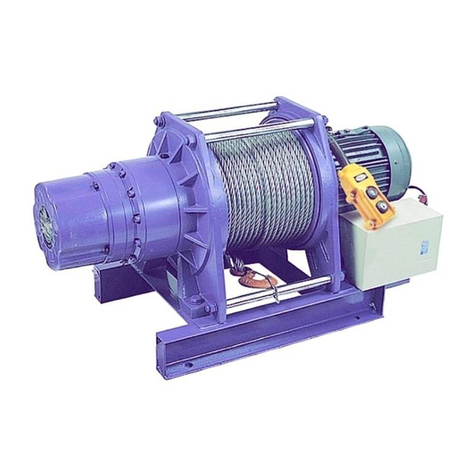

Electric Grooved Winch

Model: CEP-3001-9/11/14MD

P/N: 275950-8MD 277339-11MD 270105-14MD 380V50Hz

Feature

Lifting Capacity 3,000 kg, double fall load

Power Source 3 phase 50 Hz 380V

Motor 7.5 hp x 4 p

Drum Grooved

Wire Rope 12 mm x 22 m for PN:275950

12 mm x 28 m for PN:277339

12 mm x 34 m for PN:270105

Lifting Height 8 m for PN:275950,11 m for PN:277339,14 m for PN:270105

Lifting Speed 7 m/min, double fall load

Brake Electromagnetic spring-applied failsafe brake

Control Pendant switch w/cord 3.5 mm2

x 5C x 3 m

Read this manual carefully

You should carefully read and understand this manual before operating it.

Careless winch operation may result in personal injury hazards or property

damage

Warning

.The winch is not intended to be used in any manner for the movement or

lifting of personnel.

.The lifting capacity shown is based on single fall rope on the drum.

.The rope winding on the drum shall remain 3 wraps from the drum.

Information requesting or parts ordering

Please specify the followings information:

.Winch PN

.Serial number

.Part description

.Replacement part number

.Quantity for each part

Maintenance and Inspection

Classification of checks

Checking Item Checking

Method Checking Reference

Daily

Periodical

One

month

Three

month

One

year

◎Marking Label and the

like Visual Existence of label

◎

Installation

Winding-in

direction of

wire rope

Visual ,

measuring

Fleet angle

θ=within 3.0 degree

◎

Loosing and

centre run-out

foundation

Checking of

installing bolts Existence of abnormality

◎

Control

Switch

Working Manual Reasonable actuation

◎

Condition of

clamping of

wiring

Decomposition

checking

Confirming of accuracy

of fastening condition

◎Wearing of

contact point

Decomposition

checking

To be free from

remarkable wearing and

damage

◎Outer damage

of lead Visual To be free from exposure

of conductive wire

◎◎

Attaching

condition of

earth line

Visual

Existence of

abnormalities of

connecting wires

◎Condition of

insulation

Measure with

500v insulation-

Resistance tester

1MΩmin

◎

Motor

Condition

of insulation

Measure with

resistance tester 1MΩmin

◎Staining

damage

Decomposition

check

Existence of

abnormalities

◎

Brake

Braking gap Measuring Within 0.35 mm

◎Wearing of

disc

Decomposition

check

To be free from

remarkable wear and

damage

◎◎Performance Visual

Distance to be not more

than 1.5% of rope length

to be wound-in during 1

minute

◎

Gear

Damage ,

wearing

Decomposition

check

To be free from

remarkable wear and

damage

◎Condition of

grease feeding Measuring

Existence of suitability of

amount and deterioration

with grease Mobilux

EP2.Shell Unedo 2 or

Esso Beacon EP2