Deif AWC 500 Quick start guide

Other manuals for AWC 500

1

Table of contents

Other Deif Controllers manuals

Deif

Deif GPC-3 Hydro User manual

Deif

Deif AGC-4 Mk II User manual

Deif

Deif AGC 200 Series User manual

Deif

Deif GC-1F User manual

Deif

Deif GPC-3 Hydro User manual

Deif

Deif AGC-4 Mk II User manual

Deif

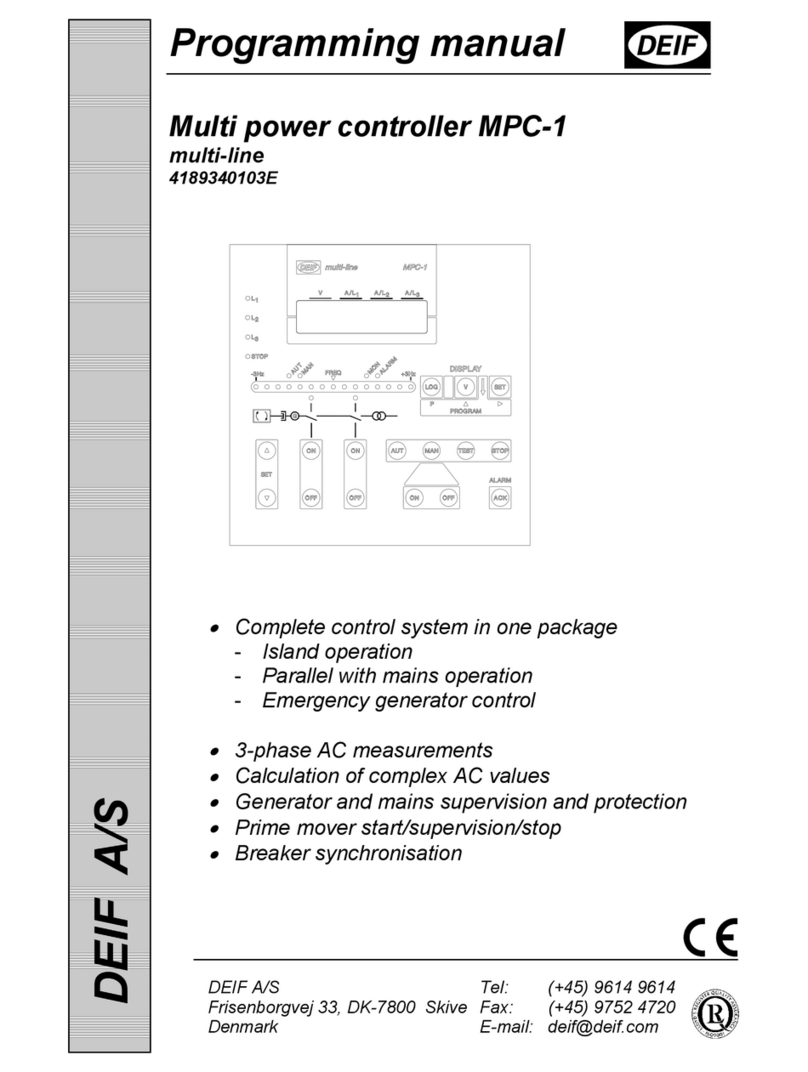

Deif MPC-1 Owner's manual

Deif

Deif AGC 100 User manual

Deif

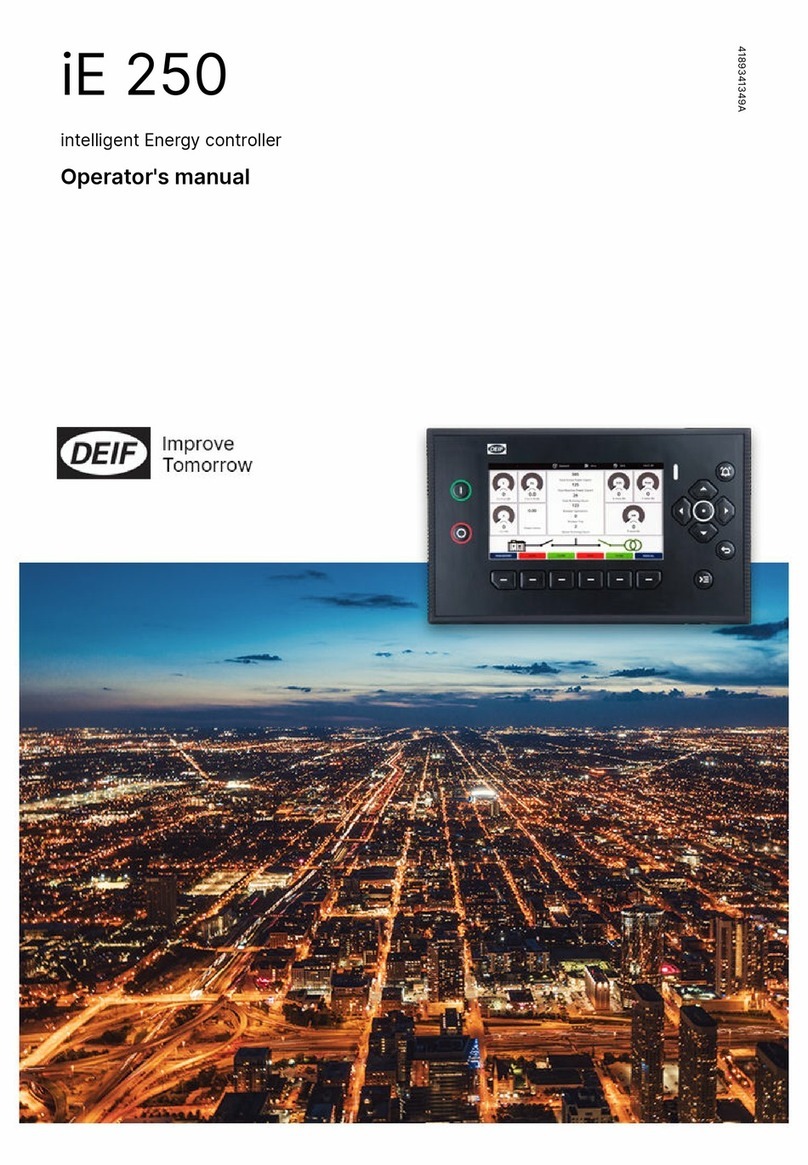

Deif iE 250 User manual

Deif

Deif AGC-4 Mk II User manual

Popular Controllers manuals by other brands

NEC

NEC N8103-197 Notes on Use

THOMSON

THOMSON MEC 310 - WITH OPTION A AUTOMATIC MAINS... Operator's manual

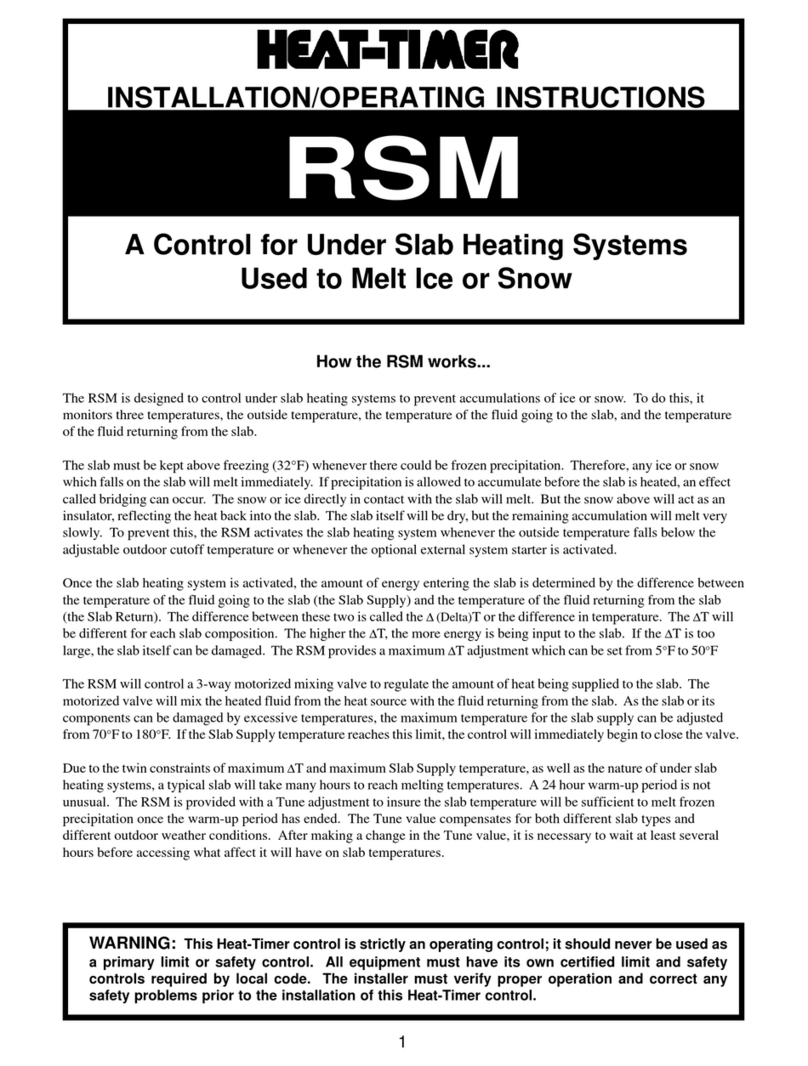

heat-timer

heat-timer RSM Installation & operating instructions

Hiwin

Hiwin RC4 Original instruction

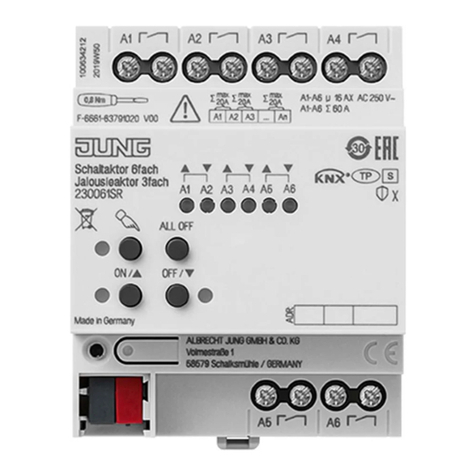

Jung

Jung 230061SR operating instructions

Freescale Semiconductor

Freescale Semiconductor MC1322x Reference manual

Laing Innotech

Laing Innotech LTC Series Installation and operating instruction

GO2

GO2 RH1 operating instructions

Hubbell

Hubbell Electric Fire Pump Controllers LXi 1700 Specifications

FAIRFORD ELECTRONICS LIMITED

FAIRFORD ELECTRONICS LIMITED DFE-30 installation instructions

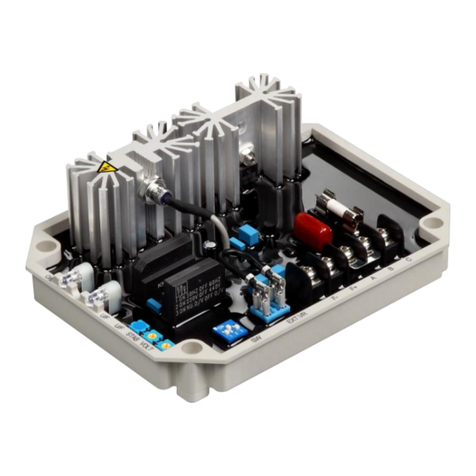

Kutai electronics

Kutai electronics ADVR-073 Operation manual

dji

dji N3 quick start guide