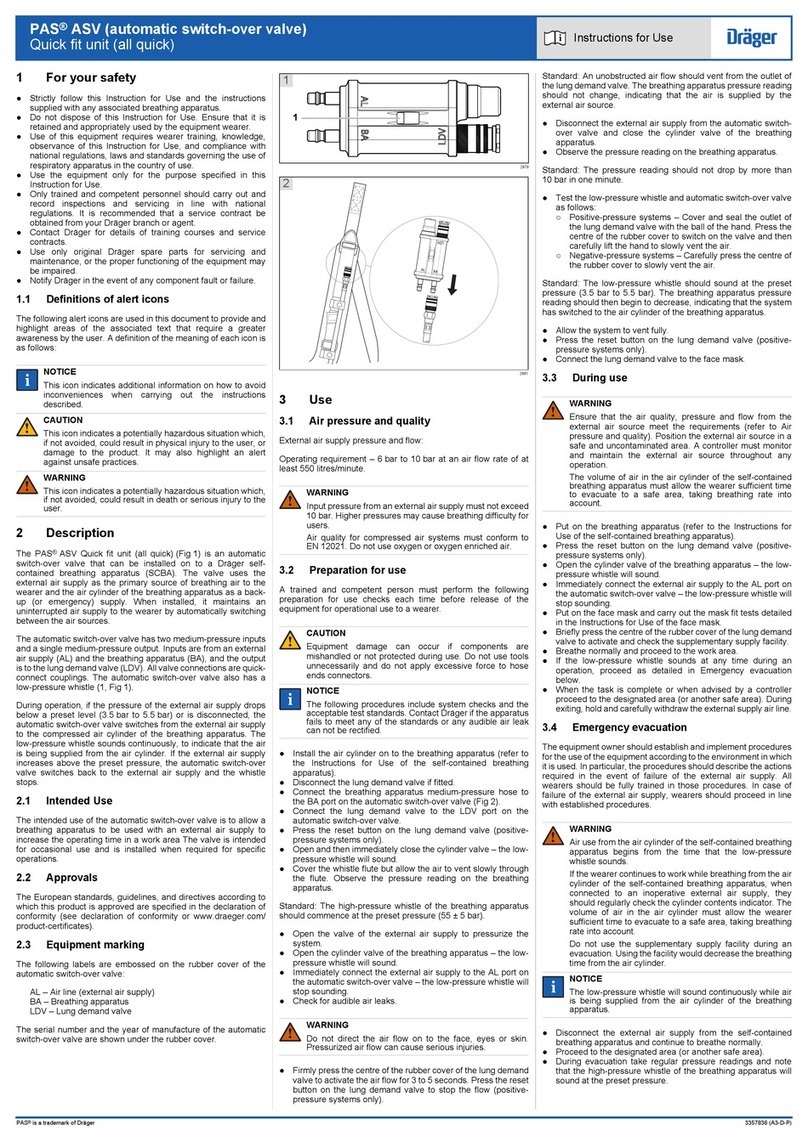

Maintenance

Instructions for use | Dräger HPS SafeGuard 5

1. Put on the fire helmet.

2. Close the chin strap.

3. Adjust the length of the chin strap at the quick-release

buckle. Fix the end of the chin strap with the hook-and-

loop fastener. The chin strap should lie evenly under the

chin.

4. Adjust the length of the neck straps using the adjusting

clamps. The neck straps should lie evenly at the neck.

5. Turn the adjusting wheel until the support ring fits snugly

against your head.

4.2.3 Taking off the helmet

1. Turn the adjusting wheel until the support ring fits loosely

on your head.

2. Open the chin strap.

3. Take off the fire helmet.

4.3 During use

The helmet does not contain any materials that are known

to cause allergic reactions. In individual cases, however,

allergic reactions could still occur in very sensitive people.

The visors may transfer physical impacts to corrective glasses

and damage them.

Full protection can only be achieved when the face protector

is locked into the lowest position.

4.4 After use

Check usability as follows:

– Check helmet shell, internal helmet components, chin

strap and accessories. Replace defective parts.

– Check visor. In case of visible damage, or impaired vision

(e. g. by scratches, discolouring), the visor should be

replaced.

– Check the paint coating of the fire helmet for damage.

The special self-extinguishing coating is the most

important factor for the thermal performance of the helmet.

Damaged coating might shorten the usage period. Small

surface scratches or damages to the paint work do not

reduce the protective effect. They can be repaired with

repair paint.

Fire helmets that are out of use, or cannot be repaired any

more must be destroyed for safety reasons.

Trained personnel or Dräger can check and decide if a

damaged fire helmet is still suitable for use or can be repaired.

CAUTION

The protective effect is reduced after impact!

If the fire helmet absorbs the energy of an impact, it can get

damaged or destroyed.

► Even if the damage is not visible at first, the fire helmet

must be replaced after a heavy bump or impact. Damaged

or impact-stressed fire helmets may no longer be used.

This also applies if no external damage is visible.

5 Maintenance

5.1 Maintenance intervals

Dräger recommends replacing the O-rings on the face

protector as required. For further information see: "Replacing

the face protector", page 6.

Dräger recommends replacing the O-rings on the adjusting

wheel every 6 years. For further information see: "Replacing

the O-ring on the adjusting wheel", page 15.

5.2 Maintenance work

The following maintenance work is normally not carried out by

the firefighter, but by service personnel.

– Replacing the neck guard

– Replacing the face-guard

– Replacing the internal helmet components

– Replacing the function plate

– Replacing the front plate

– Replacing the helmet end plate

– Replacing O-rings

– Replacing the reflective strips

– Repairing paint on the helmet shell

The photos of the helmet are examples.

5.2.1 Replacing the neck guard

Spare parts required:

– Neck guard (3702761)

1. Loosen the hook-and-loop fastener on the front adjusting

ring on both sides.

2. Pull the mounts on the rear adjusting ring to the middle of

the helmet and pull off the neck guard.

56283