PAS®ASV (automatic switch-over valve)

Quick fit unit (all quick) Instructions for Use

PAS®is a trademark of Dräger 3357836 (A3-D-P)

1 For your safety

●Strictly follow this Instruction for Use and the instructions

supplied with any associated breathing apparatus.

●Do not dispose of this Instruction for Use. Ensure that it is

retained and appropriately used by the equipment wearer.

●Use of this equipment requires wearer training, knowledge,

observance of this Instruction for Use, and compliance with

national regulations, laws and standards governing the use of

respiratory apparatus in the country of use.

●Use the equipment only for the purpose specified in this

Instruction for Use.

●Only trained and competent personnel should carry out and

record inspections and servicing in line with national

regulations. It is recommended that a service contract be

obtained from your Dräger branch or agent.

●Contact Dräger for details of training courses and service

contracts.

●Use only original Dräger spare parts for servicing and

maintenance, or the proper functioning of the equipment may

be impaired.

●Notify Dräger in the event of any component fault or failure.

1.1 Definitions of alert icons

The following alert icons are used in this document to provide and

highlight areas of the associated text that require a greater

awareness by the user. A definition of the meaning of each icon is

as follows:

NOTICE

This icon indicates additional information on how to avoid

inconveniences when carrying out the instructions

described.

CAUTION

This icon indicates a potentially hazardous situation which,

if not avoided, could result in physical injury to the user, or

damage to the product. It may also highlight an alert

against unsafe practices.

WARNING

This icon indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury to the

user.

2 Description

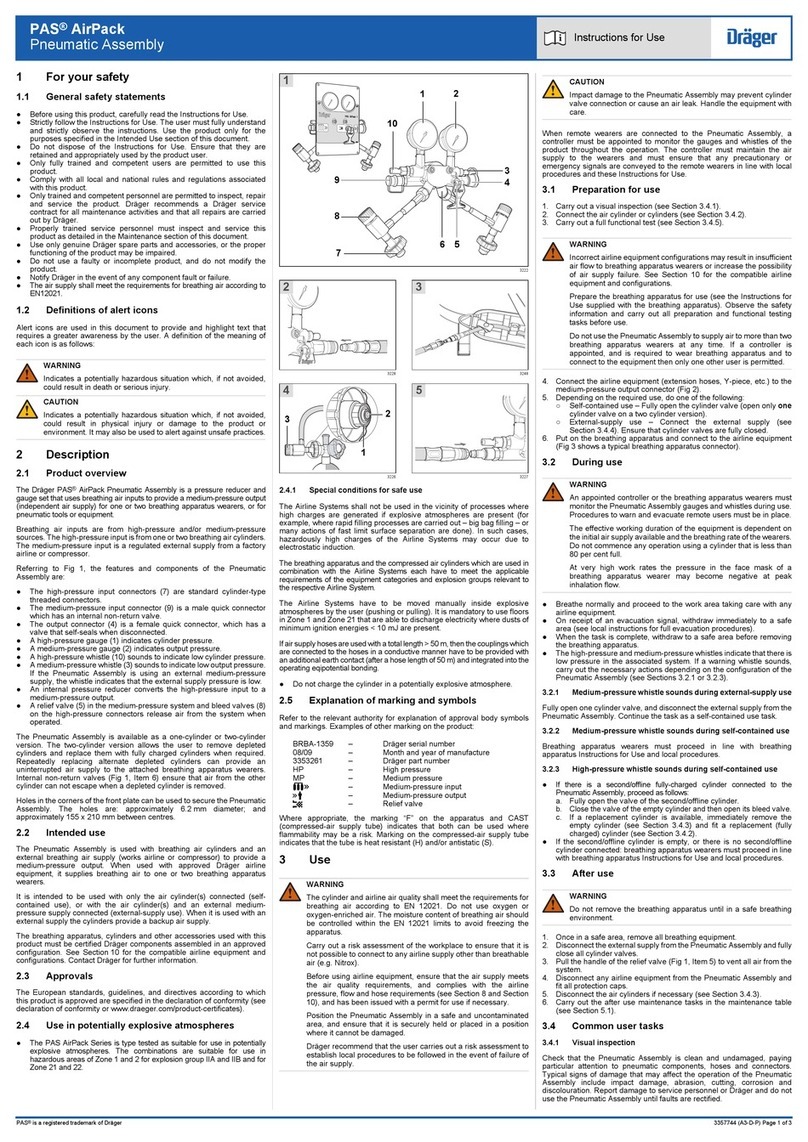

The PAS®ASV Quick fit unit (all quick) (Fig 1) is an automatic

switch-over valve that can be installed on to a Dräger self-

contained breathing apparatus (SCBA). The valve uses the

external air supply as the primary source of breathing air to the

wearer and the air cylinder of the breathing apparatus as a back-

up (or emergency) supply. When installed, it maintains an

uninterrupted air supply to the wearer by automatically switching

between the air sources.

The automatic switch-over valve has two medium-pressure inputs

and a single medium-pressure output. Inputs are from an external

air supply (AL) and the breathing apparatus (BA), and the output

is to the lung demand valve (LDV). All valve connections are quick-

connect couplings. The automatic switch-over valve also has a

low-pressure whistle (1, Fig 1).

During operation, if the pressure of the external air supply drops

below a preset level (3.5 bar to 5.5 bar) or is disconnected, the

automatic switch-over valve switches from the external air supply

to the compressed air cylinder of the breathing apparatus. The

low-pressure whistle sounds continuously, to indicate that the air

is being supplied from the air cylinder. If the external air supply

increases above the preset pressure, the automatic switch-over

valve switches back to the external air supply and the whistle

stops.

2.1 Intended Use

The intended use of the automatic switch-over valve is to allow a

breathing apparatus to be used with an external air supply to

increase the operating time in a work area The valve is intended

for occasional use and is installed when required for specific

operations.

2.2 Approvals

The European standards, guidelines, and directives according to

which this product is approved are specified in the declaration of

conformity (see declaration of conformity or www.draeger.com/

product-certificates).

2.3 Equipment marking

The following labels are embossed on the rubber cover of the

automatic switch-over valve:

AL – Air line (external air supply)

BA – Breathing apparatus

LDV – Lung demand valve

The serial number and the year of manufacture of the automatic

switch-over valve are shown under the rubber cover.

i

i

!

!

3 Use

3.1 Air pressure and quality

External air supply pressure and flow:

Operating requirement – 6 bar to 10 bar at an air flow rate of at

least 550 litres/minute.

WARNING

Input pressure from an external air supply must not exceed

10 bar. Higher pressures may cause breathing difficulty for

users.

Air quality for compressed air systems must conform to

EN 12021. Do not use oxygen or oxygen enriched air.

3.2 Preparation for use

A trained and competent person must perform the following

preparation for use checks each time before release of the

equipment for operational use to a wearer.

CAUTION

Equipment damage can occur if components are

mishandled or not protected during use. Do not use tools

unnecessarily and do not apply excessive force to hose

ends connectors.

NOTICE

The following procedures include system checks and the

acceptable test standards. Contact Dräger if the apparatus

fails to meet any of the standards or any audible air leak

can not be rectified.

●Install the air cylinder on to the breathing apparatus (refer to

the Instructions for Use of the self-contained breathing

apparatus).

●Disconnect the lung demand valve if fitted.

●Connect the breathing apparatus medium-pressure hose to

the BA port on the automatic switch-over valve (Fig 2).

●Connect the lung demand valve to the LDV port on the

automatic switch-over valve.

●Press the reset button on the lung demand valve (positive-

pressure systems only).

●Open and then immediately close the cylinder valve – the low-

pressure whistle will sound.

●Cover the whistle flute but allow the air to vent slowly through

the flute. Observe the pressure reading on the breathing

apparatus.

Standard: The high-pressure whistle of the breathing apparatus

should commence at the preset pressure (55 ± 5 bar).

●Open the valve of the external air supply to pressurize the

system.

●Open the cylinder valve of the breathing apparatus – the low-

pressure whistle will sound.

●Immediately connect the external air supply to the AL port on

the automatic switch-over valve – the low-pressure whistle will

stop sounding.

●Check for audible air leaks.

WARNING

Do not direct the air flow on to the face, eyes or skin.

Pressurized air flow can cause serious injuries.

●Firmly press the centre of the rubber cover of the lung demand

valve to activate the air flow for 3 to 5 seconds. Press the reset

button on the lung demand valve to stop the flow (positive-

pressure systems only).

!

i

i

Standard: An unobstructed air flow should vent from the outlet of

the lung demand valve. The breathing apparatus pressure reading

should not change, indicating that the air is supplied by the

external air source.

●Disconnect the external air supply from the automatic switch-

over valve and close the cylinder valve of the breathing

apparatus.

●Observe the pressure reading on the breathing apparatus.

Standard: The pressure reading should not drop by more than

10 bar in one minute.

●Test the low-pressure whistle and automatic switch-over valve

as follows:

○Positive-pressure systems – Cover and seal the outlet of

the lung demand valve with the ball of the hand. Press the

centre of the rubber cover to switch on the valve and then

carefully lift the hand to slowly vent the air.

○Negative-pressure systems – Carefully press the centre of

the rubber cover to slowly vent the air.

Standard: The low-pressure whistle should sound at the preset

pressure (3.5 bar to 5.5 bar). The breathing apparatus pressure

reading should then begin to decrease, indicating that the system

has switched to the air cylinder of the breathing apparatus.

●Allow the system to vent fully.

●Press the reset button on the lung demand valve (positive-

pressure systems only).

●Connect the lung demand valve to the face mask.

3.3 During use

WARNING

Ensure that the air quality, pressure and flow from the

external air source meet the requirements (refer to Air

pressure and quality). Position the external air source in a

safe and uncontaminated area. A controller must monitor

and maintain the external air source throughout any

operation.

The volume of air in the air cylinder of the self-contained

breathing apparatus must allow the wearer sufficient time

to evacuate to a safe area, taking breathing rate into

account.

●Put on the breathing apparatus (refer to the Instructions for

Use of the self-contained breathing apparatus).

●Press the reset button on the lung demand valve (positive-

pressure systems only).

●Open the cylinder valve of the breathing apparatus – the low-

pressure whistle will sound.

●Immediately connect the external air supply to the AL port on

the automatic switch-over valve – the low-pressure whistle will

stop sounding.

●Put on the face mask and carry out the mask fit tests detailed

in the Instructions for Use of the face mask.

●Briefly press the centre of the rubber cover of the lung demand

valve to activate and check the supplementary supply facility.

●Breathe normally and proceed to the work area.

●If the low-pressure whistle sounds at any time during an

operation, proceed as detailed in Emergency evacuation

below.

●When the task is complete or when advised by a controller

proceed to the designated area (or another safe area). During

exiting, hold and carefully withdraw the external supply air line.

3.4 Emergency evacuation

The equipment owner should establish and implement procedures

for the use of the equipment according to the environment in which

it is used. In particular, the procedures should describe the actions

required in the event of failure of the external air supply. All

wearers should be fully trained in those procedures. In case of

failure of the external air supply, wearers should proceed in line

with established procedures.

WARNING

Air use from the air cylinder of the self-contained breathing

apparatus begins from the time that the low-pressure

whistle sounds.

If the wearer continues to work while breathing from the air

cylinder of the self-contained breathing apparatus, when

connected to an inoperative external air supply, they

should regularly check the cylinder contents indicator. The

volume of air in the air cylinder must allow the wearer

sufficient time to evacuate to a safe area, taking breathing

rate into account.

Do not use the supplementary supply facility during an

evacuation. Using the facility would decrease the breathing

time from the air cylinder.

NOTICE

The low-pressure whistle will sound continuously while air

is being supplied from the air cylinder of the breathing

apparatus.

●Disconnect the external air supply from the self-contained

breathing apparatus and continue to breathe normally.

●Proceed to the designated area (or another safe area).

●During evacuation take regular pressure readings and note

that the high-pressure whistle of the breathing apparatus will

sound at the preset pressure.