_______________________________________________________________________________________________________________________________

European

Safety

Systems

Ltd.

Impress House, Mansell Road, Acton, London W3 7QH [email protected]m Tel: +44 (0)208 743 8880 www.e-2-s.com Fax: +44 (0)208 740 4200

Document No.D156-00-401-IS Issue 1 08-07-16 Sheet 1 of 5

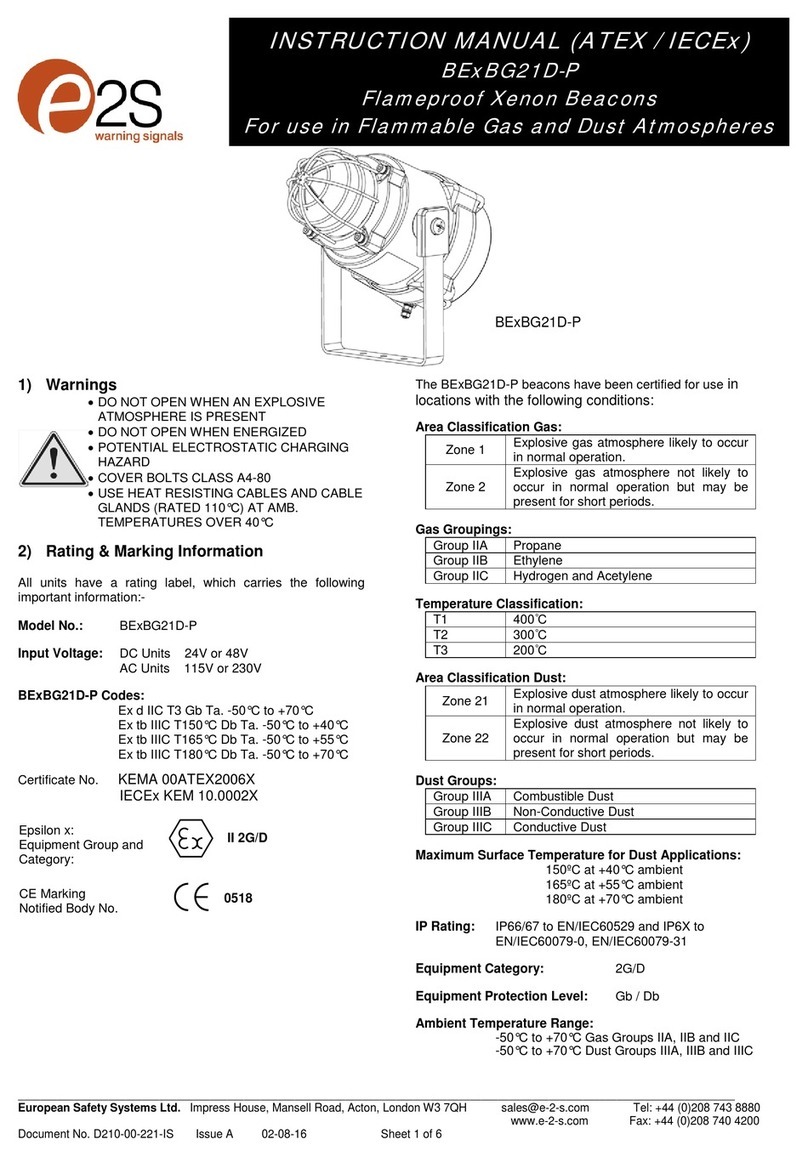

GNExB2LD2 Flameproof LED Bea ons

For use in Flammable Gas and Dust Atmospheres

1) Introduction

The GNExB2LD2 are flameproof beacons which are certified

to meet the requirements of the ATEX directive 94/9/EC and

the IECEx scheme. The beacon produces synchronised

visual warning signals and can be used in hazardous areas

where potentially flammable gas and dust atmospheres may

be present. The GNExB2LD2 can be used in Zone 1 and

Zone 2 areas with gases in groups IIA, IIB and IIC and

Temperature Classifications of T1, T2, T3, T4, T5 & T6. The

unit can be used in Zone 21 and Zone 22 with dusts in

groups IIIA, IIIB and IIIC and have a surface temperature

rating of T85°C.

2) Marking

All units have a rating label, which carries the following

important information:-

Input Voltage: DC Units 24V

AC Units 230V or 115V

GNExB2LD2

Codes:

Ex db IIC Gb T6 Ta -50°C to +65°C

Ex db IIC Gb T5 Ta -50°C to +70°C

Ex tb IIIC Db T85°C Ta -50°C to +70°C

Certificate No.

DEMKO 15ATEX1448X

IECEx UL15.0003X

“Warnings”

POTENTIAL ELECTROSTATIC CHARGING HAZARD

DO NOT OPEN WHEN AN EXPLOSIVE

ATMOSPHERE IS PRESENT

ALL ENTRIES M20 X 1.5

IF TEMPERATURE EXCEEDS 70ºC AT ENTRY OR 80ºC AT

BRANCHING POINT USE SUITABLE RATED CABLE AND CABLE

GLANDS

3)

Type Approval Standards

The beacons have an EC Type examination certificate and

IECEx certificate of conformity issued by UL and have been

approved to the following standards:

EN60079-0:2012 / IEC60079-0:2011 (Ed 6): Explosive Atmospheres

- Equipment. General requirements

EN60079-1:2014 / IEC60079-1:2014 (Ed 7): Explosive Atmospheres

- Equipment protection by flameproof enclosures "d"

BS EN 60079-31:2014 / IEC 60079-31:2013 (Ed 2): Explosive

Atmospheres - Equipment dust ignition protection by enclosure "t"

4)

Installation Requirements

The beacons must only be installed by suitably qualified

personnel in accordance with the latest issues of the relevant

standards:

EN60079-14 / IEC60079-14: Explosive atmospheres - Electrical

installations design, selection and erection

EN60079-10-1 / IEC60079-10-1: Explosive atmospheres -

Classification of areas. Explosive gas atmospheres

EN60079-10-2 / IEC60079-10-2: Explosive atmospheres -

Classification of areas. Explosive dust atmospheres

The installation of the units must also be in accordance with

any local codes that may apply and should only be carried

out by a competent electrical engineer who has the

necessary training.

5)

Zones, Gas Group, Category, IP Rating and

Temperature Classification

The units can be installed in locations with the following

conditions:

Area Classification Gas:

Zone 1 Explosive gas air mixture likely to occur in

normal operation.

Zone 2 Explosive gas air mixture not likely to occur,

and if it does, it will only exist for a short time.

Gas Groupings:

Group IIA Propane

Group IIB Ethylene

Group IIC Hydrogen and Acetylene

Temperature Classification:

T1 450ºC

T2 300ºC

T3 200ºC

T4 135ºC

T5 100ºC

T6 85ºC (up to 65ºC ambient)

Area Classification Dust:

Zone 21 Explosive dust air mixture likely to occur in

normal operation.

Zone 22 Explosive dust air mixture not likely to occur, and

if it does, it will only exist for a short time.

Dust Groupings:

Group IIIA Combustible Flyings

Group IIIB Non-conductive Dust

Group IIIC Conductive Dust

IP Rating: IP6X to EN/IEC60079-0 and IP66 to EN/IEC60529

Equipment Category: 2G/D

Ambient Temperature Range: -50°C to +70°C

Maximum Surface Temperature for Dust Applications:

85ºC

0518

II 2D

Epsilon x

Equipment Group and

Category:

CE Marking

Notified Body No.