66A5400H01

MiniMod Un-Packing and Incoming Inspection:

If the MiniMod is to be placed in storage, maximum protection can be obtained by keeping it packed as

shipped. Before placing it in storage, checks should be made to make sure that the unit is free from shipping

damage and is in satisfactory operating condition.

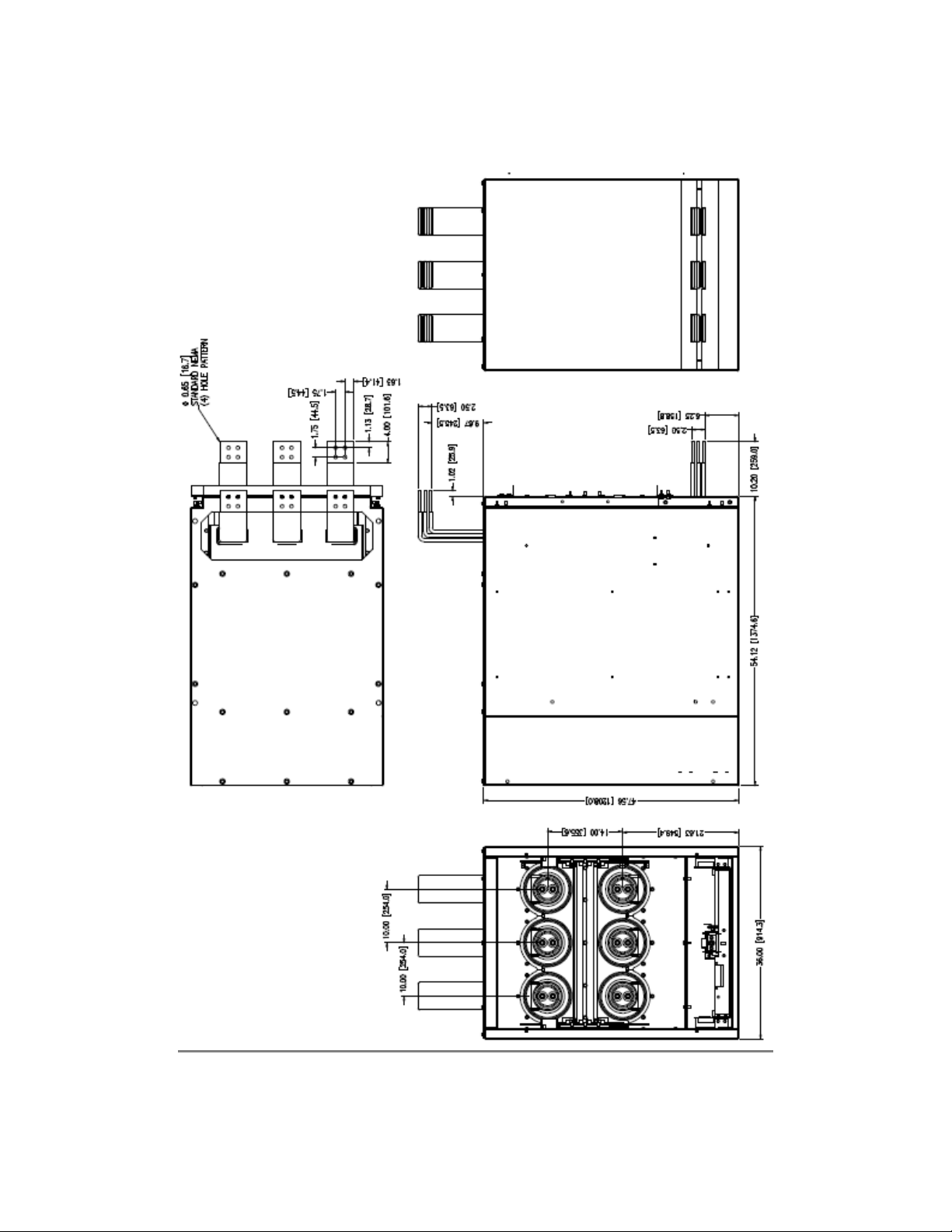

The MiniMod is shipped within a wood crate. When it arrives and needs to be unpacked then the

top of the crate should be removed first. Then the sides should be removed. The unit should be

kept on the bottom pallet temporarily. Inspect the unit for shipping damage and or missing parts.

Make sure the red brick colored spouts in the back of the units do not have any significant cracks.

If any problems are found then please contact your local Eaton Salesman or EESS for repair /

replacement parts. The unit can now be moved around via a pallet jack and or fork lift truck.

Eaton suggests moving the unit around attached to the pallet. This is due to the large size of the

unit and the unbalanced weight of the unit. Eaton suggests the wood crate be saved in storage as

long as possible in case it is needed. The MiniMod is supplied with lifting hooks and or lifting

metal strips located on the top of the unit. A large overhead crane can be used to life the unit.

These lifting hooks or lifting metal straps can be removed during the installation process.

MiniMod Operational Inspection:

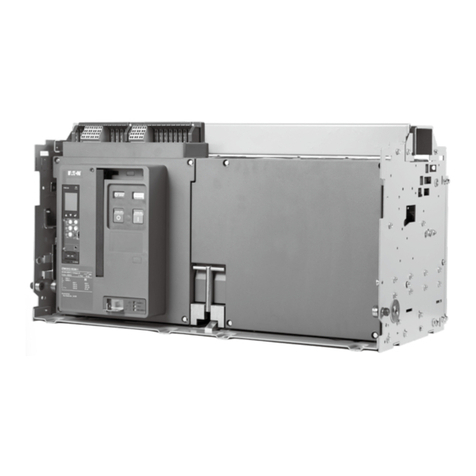

It is best to perform this testing with the MiniMod on the pallet outside of the switchgear. We do not

suggest you mount the MiniMod in the switchgear and then perform these tests. Testing with just the

breaker and MiniMod allows for the user to see the operation from all sides and avoid any damage to the

breaker and or MiniMod.

Test the operation of the left hand and right hand shutter drivers by pushing them by hand forward and

backwards. If binding is found then try to remove the foreign item causing the binding. If required grease

the parts to improve the operation.

Frequency of Inspection and Maintenance:

Periodic inspections and associated maintenance are essential to the safe and reliable operation of the

MiniMod and VCP-WG Vacuum Circuit Breaker Elements. The inspection frequency and associated

maintenance recommended are intended to insure the best possible ongoing service. It is imperative that an

established schedule be followed. To establish an exact schedule for a specific installation, use the following

guidelines:

1. Customers such as Utilities having extensive experience with Power Distribution components should

schedule their inspection and maintenance intervals using well established best practices in their industry.

2. All other customers should use the following guidelines as good conservative practice:

a. In a clean, non-corrosive environment, inspect and maintain each MiniMod annually or after

every 100 levering in operations, whichever comes first.