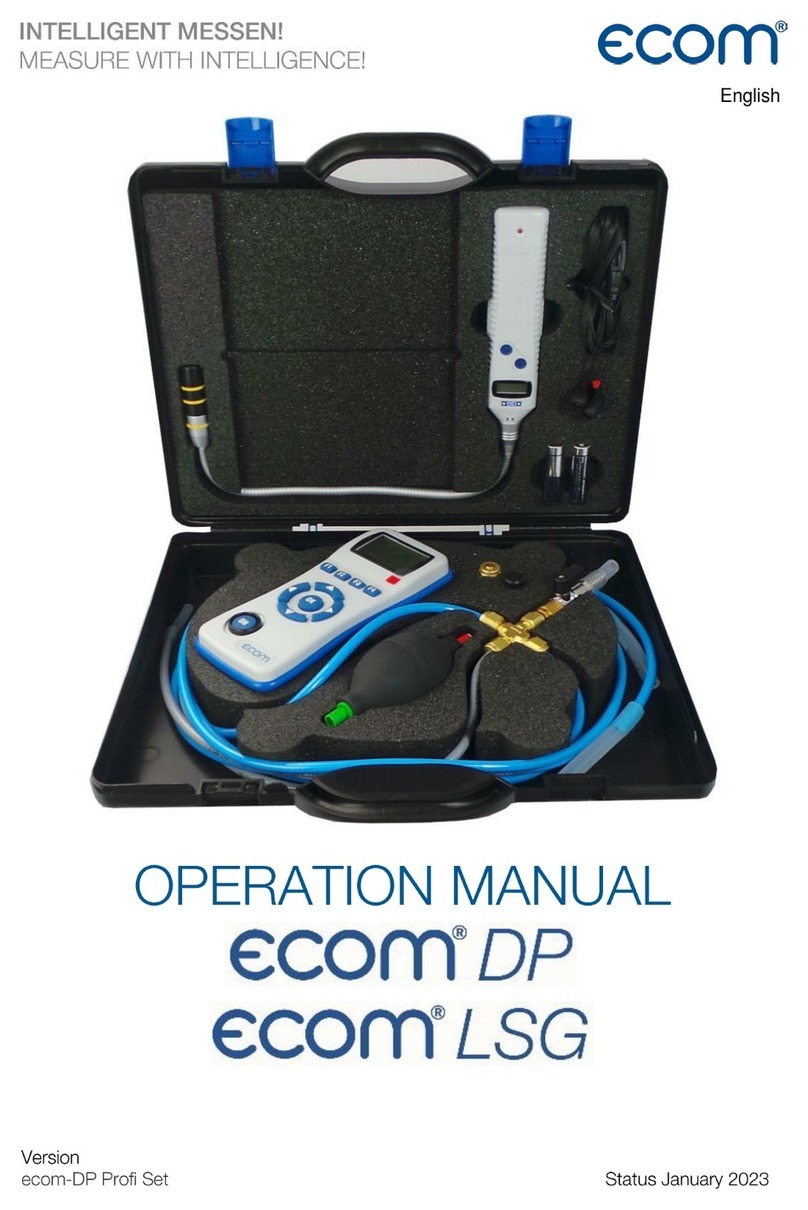

Ecom DP User manual

English

2

Index

1. Design ecom-DP.................................................................................................3

2. Initialisation .........................................................................................................3

2.1. Power supply ..............................................................................................4

2.2. Accumulator charging.................................................................................4

2.3. Setting clock................................................................................................4

3. Numerical indication............................................................................................5

3.1. Zeroing the internal pressure sensor..........................................................6

3.2. Freezing of measurement value.................................................................6

3.3. Minimal / Maximal measurement values ....................................................7

3.4. Measurement values printout .....................................................................7

3.5. Contrast adjustment and lighting................................................................7

4. Check programs..................................................................................................8

4.1. Setup...........................................................................................................8

4.2. Pressure check...........................................................................................9

4.3. Preliminary check .......................................................................................9

4.4. Main Check...............................................................................................11

4.5. Usability Check.........................................................................................12

5. Clock set ...........................................................................................................14

6. Internal instrument settings...............................................................................15

6.1. Key beep on/off switch..............................................................................15

6.2. Pressure Auto -> 0 by start.......................................................................16

6.3. Choose printer (ecom-P) ..........................................................................16

6.4. Battery loading..........................................................................................16

6.5. Display damping .......................................................................................16

6.6. Pressure unit.............................................................................................17

6.7. Auto OFF function.....................................................................................18

6.8. Contrast ....................................................................................................18

6.9. Light..........................................................................................................18

7. Sensor setup.....................................................................................................19

8. View service information...................................................................................19

9. Data logger program „ecom-DP Logger“ ..........................................................20

10. Technical Data ecom-DP................................................................................21

11. Maintenance tip...............................................................................................22

3

1. Design ecom-DP

Connections

Pmax = 1500 hPa

Connections (Option)

Pmax = 1500 hPa

oder Pmax = 70 hPa

IR interface

(for IR printer)

Function keys

(current function is

shown on display)

Connection loa-

ding unit

Graphic display

Cursor keys

OK-key

ON/OFF key

4

2. Initialisation

2.1. Power supply

The ecom-DP is powered by 3 batteries or 3 accumula-

tors. The following types can be used to operate the in-

strument:

- Battery 1,5 V AA (Mignon)

- Battery 1,2 V AA NiCd (nickel cadmium)

- Battery 1,2 V AA NiMh (metal hydride)

If you are using a loading unit, please adjust the function

„Bat. Loading“ (see chapter 6.4.)

Open the battery compartment and insert the batteries.

Be careful to ensure proper polarity. If using the re-

chargeable battery type, it will be necessary to fully

charge the batteries prior to initial use (approx. 4 hours).

The voltage of the batteries is monitored by the DP and

will indicate a low battery condition by approx. 3.3 V by

beeping and flashing a signal on the LCD display. If the

voltage sinks (approx. 3 V) so the ecom-DP will automat-

ically switch off.

2.2. Accumulator charging

The accumulator charging procedure is monitored by the

ecom-DP. Once connected to AC power, the instrument

switches on. During the charging procedure, a BATTERY

indicator will be shown on the LCD display. Once the bat-

tery is fully charged, the BATTERY indicator on the dis-

play will blink. It is possible to operate the ecom-DP on

AC power during the charging procedure by pressing the

<ON> button.

2.3. Setting clock

The internal clock and the internal RAM memory of the

ecom-DP are buffered via a capacitor. If the instrument

is without current supply during more than approx. 10

minutes, the recorded information gets lost. Before using

the ecom-DP for the first time, adjust the internal clock

and delete the internal RAM memory.

Battery warning

5

Press <ON> to switch on the ecom-DP.

The instrument displays the following:

Clock set

Delete RAM

Press OK to continue!

- Press twice the <OK> key and the measurement value

menu will be displayed.

- Press <F2> (wrench symbol) to call up the menu „In-

strument settings“.

- With the cursor keys <UP/DOWN> scroll until the menu

point “Set clock”.

- Press <OK> to activate.

Date and time can be set as follows:

1. Select with the cursor keys <RIGHT/LEFT> the posi-

tion to be changed (corresponding field blinks).

2. Adjust the correct numbers with the cursor keys

<UP/DOWN>.

3. Press <OK> to confirm correct date and time settings.

3. Numerical indication

After switch-on, the specifications of the pressure sensor

will be displayed: denomination, measurement range and

connection seizure (+/-). Press <OK> to access to the

measurement value menu.

1. Before making measurements, the instrument must have

adapted the ambient temperature!

2. Make sure, that the ambient temperature remains constant

during measurement!

If „Pressure Auto -> O by start“ is set on

„YES“ (Chapter 6.2), so the internal pres-

sure sensors should be flown with pres-

sure first after the switch-on of the instru-

ment, as they are zeroed during

said switch-on procedure.

6

3.1. Zeroing the internal pressure sensor

As the difference pressure sensor can drift because of its

sensitivity in the zero point (also by attaching to metal

surfaces by magnetic holder), it is possible to reset the

zero point.

- Press <F2> (DP->0) to activate the function for zero-

point correction of the pressure sensors.

- Press <F3> (DP1) to zero the value of the pressure sen-

sor 1.

- Press <F4> (DP2) to zero the value of the pressure sen-

sor 2.

- Press <F2> (ESC) to quit the menu.

Different functions can be called up with the function key

<F1>. The current seizure of the other function keys

(<F2> - <F4>) is shown on the display. Press one time

<F1> to display the functions „Hold“, „Min/Max“ and

„Print“.

3.2. Freezing of measurement value

- Press <F2> (Hold) to „freeze“ that measurement value

displayed at the time the key is pressed (active function

= Hold indication blinks).

- Press again <F2> (Hold) to quit the „freezing“ and the

current value will be displayed.

If the instrument is attached to a metal surface with the magnetic

holders, the zero point may shift.

Please reset the zero point before measurement.

7

3.3. Minimal / Maximal measurement values

With <F3> (Min/Max) the determined minimal and maxi-

mal values since unit switch-on (or deleting via „CLR“)

can be called up.

- Press one time <F3> (Min/Max) to view the lowest de-

termined values (Min/Max blinks).

- Press <F2> (CLR) to delete the minimal values (new

scanning begins).

- Press again <F3> (Min) to view the highest values

(Min/Max blinks).

- Press <F2> (CLR) to delete the highest values (new

scanning begins).

- Press one more time <F3> (Max) to quit the menu.

3.4. Measurement values printout

Press <F4> (Print) to transmit the current measurement

values via the infrared interface to the IR printer (option).

Condition hereto is a trouble-free connection (direct

sight) between the sending diode at the front of the in-

strument and the receiving diode of the printer. The dis-

tance between both instruments should not exceed 40

cm (1.3 foot), otherwise a trouble-free transmission is not

warranted at any time.

3.5. Contrast adjustment and lighting

Basing on the previous function seizure, the functions

„LUMI“ and „Light“ are displayed after pressing <F1>.

The graphic display of the ecom-DP can be adjusted to

different visual conditions. The contrast can be adjusted

in 5 steps (each key pressing = one step) while pressing

<F3> (LUMI). Additionally the backlighting of the display

can be activated while pressing <F4> (Light).

-----------------------------------

ecom-DP

-----------------------------------

Date Time

05.10.01 12:12:50

-----------------------------------

P1 0.0 (hPa)

P2 0.0 (hPa)

-----------------------------------

min max

P1 -0.1 0.1 (hPa)

P2 -0.1 0.1 (hPa)

-----------------------------------

ecom GmbH

Am Grossen Teich 2

58640 Iserlohn

Tel. 02371-9455

8

4. Check programs

Call up the pre-programmed measurement routines „Pre-

liminary Check“, Main Check“ and „Usability Check“ in

the menu <F3> (PROC).

Parameters to each measurement routine can be ad-

justed in the menu „Setup“.

4.1. Setup

Scroll with <UP/DOWN> until the menu “Setup”. Press

<OK> to activate the menu. The following parameters

can be adjusted for the corresponding measurement rou-

tine:

Pressure Check

- Stabilisation time (1 - 10 min, default: 1 min)

- Measurement time (10 - 120 min, default: 5 min)

Preliminary Check

- Stabilisation time (1 - 10 min, default: 1 min)

- Measurement time (10 - 120 min, default: 10 min)

- Test pressure (900 - 1200 hPa, default: 1000 hPa)

Main Check

- Stabilisation time (1 - 10 min, default: 1 min)

- Measurement time (10 - 120 min, default: 10 min)

- Test pressure (90 - 160 hPa, default: 110 hPa)

Usability check

- Stabilisation time (1 - 270 min, default: 1 min)

- Measurement time (10 - 240 min, default: 10 min)

- Test pressure (20 - 160 hPa, default: 50 hPa)

- Max. operation pressure (10 - 100 hPa, default: 20 hPa)

- Air pressure (800 - 1200 hPa, default: 1013 hPa)

Each parameter can be adjusted the same way:

1. Select the parameter with <UP/DOWN>.

2. Press <OK> to activate.

3. Use the cursor keys <RIGHT/LEFT> to select the po-

sition to be changed (corresponding field blinks).

1. Use only air or inert gas for check !

2. Respect the „Technical Rules for

Gas Installation“!

9

4. Adjust the correct figure using <UP/DOWN>.

5. Press <OK> to confirm the corrected value.

4.2. Pressure check

Proceed as follows:

1. Close the conduit with a suitable adapter (part of

ecom-DPK).

2. Connect the components a described in ecom-DPK

manual.

3. Scroll with <UP/DOWN> until the menu „Pressure

check“. Activate with <OK>-Taste.

4. With the compressed-air pump create the pre-adjusted

test pressure (the unit beeps as soon as the pressure

level is achieved).

5. Interrupt the connection to the air pump (switch-off the

ball valve).

6. Wait for stabilisation time (if the pressure remains in

the range „test pressure +/- 10% during stabilisation time,

so the measurement time will start).

7. Once the measurement time is over, the result is dis-

played and can be sent to the IR printer (option) thus

pressing <F2> (Print).

8. If the menu „Pressure Check“ is selected again, so the

result can be called up with <F1> (as long as the ecom-

DP is on) or a new measurement can be started with

<OK>.

10

4.3. Preliminary check

The preliminary check acc. to DVGW –TRGI Process In-

structions G 600 by pipes (operation pressure up to 100

hPa) is registered as a measurement routine in the

ecom-DP.

Proceed as follows:

1. Close the conduit with a suitable adapter (part of

ecom-DPK).

2. Connect the components a described in ecom-DPK

manual.

3. Scroll with <UP/DOWN> until the menu „Preliminary

check“. Activate with <OK>-Taste.

4. With the compressed-air pump create the pre-adjusted

test pressure (the unit beeps as soon as the pressure

level is achieved).

5. Interrupt the connection to the air pump (switch-off the

ball valve).

6. Wait for stabilisation time (if the pressure remains in

the range „test pressure +/- 10% during stabilisation time,

so the measurement time will start).

7. Once the measurement time is over, the result is dis-

played and can be sent to the IR printer (option) thus

pressing <F2> (Print).

8. If the menu „Preliminary Check“ is selected again, so

the result can be called up with <F1> (as long as the

ecom-DP is on) or a new measurement can be started

with <OK>.

11

4.4. Main Check

The main check acc. to DVGW –TRGI Process Instruc-

tions G 600 by conduits (operation pressure up to 100

hPa) is registered as a measurement routine in the

ecom-DP. Proceed as follows:

1. Close the conduit with a suitable adapter (part of

ecom-DPK).

2. Connect the components a described in ecom-DPK

manual.

3. Scroll with <UP/DOWN> until the menu „Main Check“.

Activate with <OK>-Taste.

4. With the compressed-air pump create the pre-adjusted

test pressure (the unit beeps as soon as the pressure

level is achieved).

5. Interrupt the connection to the air pump (switch-off the

ball valve).

6. Wait for stabilisation time (if the pressure remains in

the range „test pressure +/- 10% during stabilisation time,

so the measurement time will start).

7. Once the measurement time is over, the result is dis-

played and can be sent to the IR printer (option) thus

pressing <F2> (Print).

8. If the menu „Main Check“ is selected again, so the re-

sult can be called up with <F1> (as long as the ecom-DP

is on) or a new measurement can be started with <OK>.

12

4.5. Usability Check

The usability check acc. to DVGW –TRGI Process form G 624 by conduits is mem-

orised as a measurement routine by the ecom-DP. The calculation of the leak rate

happens automatically according to the following equation and corresponds here-

with to the procedure of the DVGW-TRGI Process Form G 624:

VB = V/TM * ((PA + P1) / (PA + P2)-1) * PB / P1 * f

with: VB= Gas leak volume in operation state (l/h)

V = Pipe content in litres

TM= Measurement duration in hours

PA= Barometer stand in hPa

P1 = Test pressure at meas. beginning in hPa

P2 = Test pressure at measurement end in hPa

PB= Maximal gas operation pressure in hPa

f = Factor for consideration of gas type

Proceed as follows:

1. Close the conduit with a suitable adapter (part of

ecom-DPK).

2. Connect the components a described in ecom-DPK

manual.

3. Scroll with <UP/DOWN> until the menu „Suitabil-

ity/Leak rate“. Activate with <OK>.

4. The pipe volume to be checked (V) is needed for the

calculation of the leak rate. The ecom-DP offers two in-

put possibilities:

a. Direct input of pipe volume after having pressed

<F1> (ADD) (by repeated input the value will be

added).

13

b. The ecom-DP will calculate the pipe volume in sec-

tions basing on the diameter and the length for thread

pipe acc. to DIN 2440 (middle heavy):

- Press <F2> (CAL).

- Use <UP/DOWN> to select the pipe diameter (1/2“

to 4“) and confirm with <OK>.

- Select pipe length with the cursor keys and confirm

with <OK>.

- The volume for thread pipe acc. to DIN 2440 (me-

dium heavy) will be calculated and added.

- Repeat procedure until all pipe sections are regis-

tered.

5. Quit the volume input with <OK>.

6. The maximal operation pressure adjusted in the setup

(PB) will be displayed. If need be, the value can be

changed using the cursor keys. Confirm the value with

<OK>.

7. The air pressure (PA) adjusted in the setup is dis-

played. If need be, the value can be changed using the

cursor keys. Confirm with <OK>.

14

8. Use <UP/DOWN> to select the used gas type (f) and

confirm with <OK>. The following gas types are recorded

with their respective factors:

Natural gas

Air

City gas

Propane

Butane

Hydrogen

9. With the compressed-air pump create the pre-adjusted

test pressure (the unit beeps as soon as the pressure

level is achieved).

10. Interrupt the connection to the air pump (switch-off

the ball valve).

11. Wait for stabilisation time (if the pressure remains in

the range „test pressure +/- 10% during stabilisation time,

so the measurement time will start).

12. Once the measurement time is over, the result is dis-

played and can be sent to the IR printer (option) pressing

<F2> (Print).

13. If the menu „Usability Check“ is selected again, so the

result can be called up with <F1> (as long as the ecom-

DP is on) or a new measurement can be started with

<OK>.

15

5. Clock set

- Scroll with <UP/DOWN> until the menu point “Set

clock”.

- Press <OK> to activate. Date and time can be adjusted

as follows:

1. Select with <RIGHT/LEFT> the position to be changed

(corresponding field blinks).

2. Adjust the correct figures using <UP/DOWN>.

3. Confirm with <OK>.

6. Internal instrument settings

Further instrument settings can be performed in the

menu “Internal”. Press <OK> to access this menu.

6.1. Key beep on/off switch

- With the cursor keys <UP/DOWN> scroll until the menu

point “Key beep”.

- Activate with <OK>.

- With the cursor keys <RIGHT/LEFT> modify the adjust-

ment (YES or NO).

- Confirm with <OK>.

16

6.2. Pressure Auto -> 0 by start

The ecom-DP normally zeroes the internal pressure sen-

sor during switch-on (adjustment „YES“). If the instru-

ment is to remain connected to a pressure source, so this

adjustment can be modified:

- Scroll with the cursor keys <UP/DOWN> until the menu

point “Pressure auto -> 0 by start”.

- Press <OK> to activate.

- Use the cursor keys <RIGHT/LEFT> to modify the ad-

justment (YES or NO).

- Confirm the modification with <OK>.

6.3. Choose printer (ecom-P)

Please choose the used printer as follows:

- Scroll with the cursor keys <UP/DOWN> until the menu

point “ecom-P”.

- Press <OK> to activate.

- Use the cursor keys <RIGHT/LEFT> to modify the ad-

justment (YES = printer ecom-P or NO = printer HP

82240B).

- Confirm the modification with <OK>.

6.4. Battery loading

The ecom-DP is able to work with accus and AC power

(option):

- Scroll with the cursor keys <UP/DOWN> until the menu

point “Battery loading”.

- Press <OK> to activate.

- Use the cursor keys <RIGHT/LEFT> to modify the ad-

justment (YES = using AC power for charging accus or

NO = no AC power used).

- Confirm the modification with <OK>.

6.5. Display damping

The display damping can be adjusted to various meas-

urement duties. 7 damping steps can be selected (1 = no

damping; 7 = high damping).

17

Additionally the damping steps 3 - 7 enable the selection

of a damping progression. This means:

not progressive:

by massive pressure changes the display does not react

faster than by small pressure changes

low progressive:

by massive pressure changes the display reacts some-

what faster than by small pressure changes.

high progressive:

by massive pressure changes the display reacts much

faster than by small pressure changes.

- To change the adjustment, scroll with the keys

<UP/DOWN> until the menu point “Damping”.

- Press <OK> to activate.

- Adjust the desired damping step using the cursor keys

<RIGHT/LEFT>.

- Press <OK> to confirm.

6.6. Pressure unit

The measuring unit of the internal pressure sensor can

be changed. The following units are selectable:

Hectopascal hPa

Centimetre water column cmH2O

Millimetre mercury column mmHg

Pound per square inch PSI

Inch water column “H2O

Inch mercury column “Hg

For modification:

- Scroll with the cursor keys <UP/DOWN> until the menu

point “Pressure unit”.

- Press <OK> to activate.

- Use the cursor keys <RIGHT/LEFT> to adjust the de-

sired unit for the pressure sensor.

- Press <OK> to confirm.

18

6.7. Auto OFF function

The ecom-DP is able to switch off automatically after 270

sec.:

- Scroll with the cursor keys <UP/DOWN> until the menu

point “Auto OFF function”.

- Press <OK> to activate.

- Use the cursor keys <RIGHT/LEFT> to modify the ad-

justment (YES = activate the function or NO = disable the

function

- Confirm the modification with <OK>.

6.8. Contrast

The contrast of the display can be adjusted with the help

of the cursor keys <RIGHT/LEFT>:

- Scroll with the cursor keys <UP/DOWN> until the menu

point “Contrast”.

- Press <OK> to activate.

- To increase the contrast use cursor key <RIGHT>.

- To decrease the contrast use cursor key <LEFT>.

- Confirm the modification with <OK>.

6.9. Light

The lighting of the display can be switched ON and OFF.

- Scroll with the cursor keys <UP/DOWN> until the menu

point “Light”.

- Press <OK> to activate.

- Use the cursor keys <RIGHT/LEFT> to modify the ad-

justment (NO / 1, 5, 10 or 30 minutes / --- permanent light-

ing)

- Confirm the modification with <OK>.

Press <F2> (ESC) to quit the menu “Internal”.

19

7. Sensor setup

The sensors in the instrument are given factory specified

designations that can be changed by the user. Using the

<UP/DOWN> cursor keys, scroll to “Sensor setup” menu.

Press <OK>. Using the <UP/DOWN> cursor keys, select

the sensor to be renamed and enter the edit function by

pressing <OK>.

A maximum of 6 characters (letters, numbers and special

characters) can be used in the sensor designation. Using

the <UP/DOWN> cursor keys, select the position to be

changed (sign blinks). Use the <UP/DOWN> cursor keys

to select the character that should stand on this position.

Starting from the current one and using the <UP> key,

the following characters are stored in the instrument in

the following succession:

Blank sign

A - Z

a - z

Ä -Ü

ä - ß

0 - 9

Special characters

Once the renaming procedure is complete, press <OK>

to store.

8. View service information

- Use the cursor keys <UP/DOWN> to scroll thru until the

menu point “Service”.

- Press <OK> and an info window will be opened in which

the address and phone number of the competent service

centre as well as the instrument version (e.g. ECOM DP

V3.1) will be displayed.

20

9. Data logger program „ecom-DP Logger“

The measured value process of the ecom-DP can be logged with the help of the

data logger program „ecom-DP Logger “. The program can be loaded free of charge

from the download area of the ecom homepage www.ecom.de. To transfer the data

a USB cable (kind becomes. - No.: 55818) and a driver (free download from

www.ecom.de) is needed. The measured value rows can be stored in the xls format

(Excel).

The USB cable can be used as the power supply for

the ecom DP. Therefore the function „Battery loading“

must be adjusted on „no“ when using

1,5 V AA (Mignon) batteries (see 6.4.)!

Other manuals for DP

1

Table of contents

Other Ecom Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Ceraphant T PTC31 operating instructions

York Survey Supply

York Survey Supply 343680 operating instructions

Minolta

Minolta AUTO METER IIIF - PART 2 manual

Endress+Hauser

Endress+Hauser KRFB operating instructions

Chauvin Arnoux

Chauvin Arnoux CA-MA 100 user manual

pyroscience

pyroscience Piccolo2 user manual