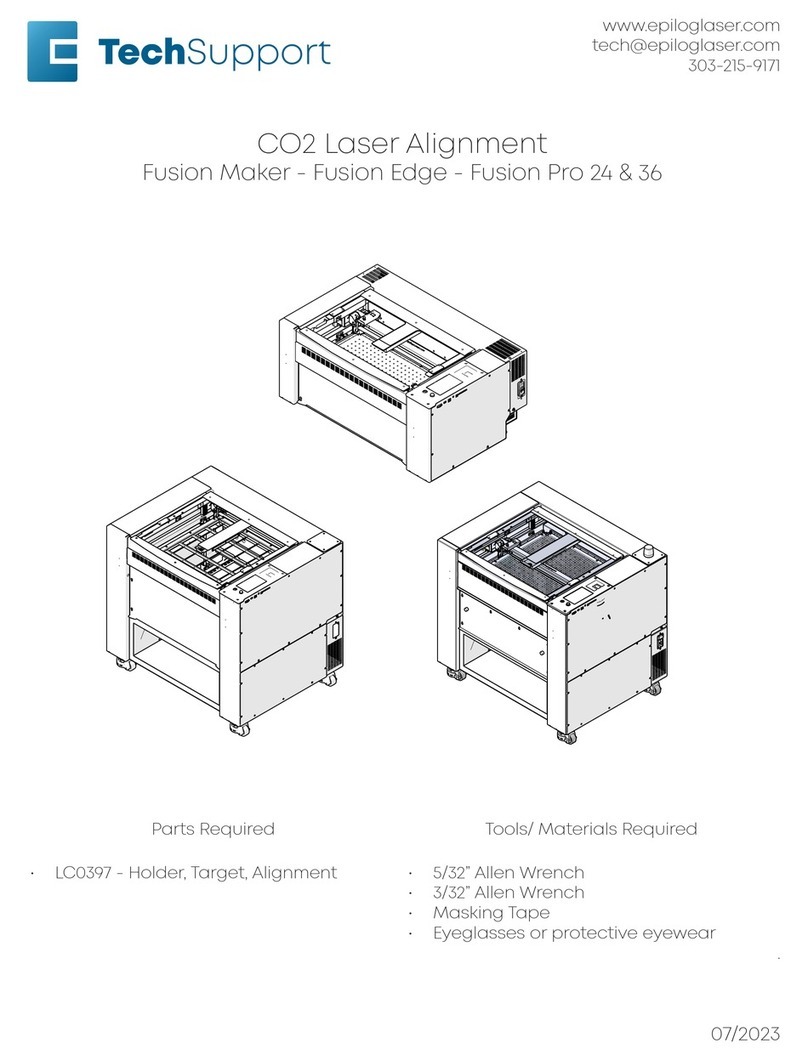

Epilog Laser Helix Installation and operation manual

Other Epilog Laser Engraver manuals

Epilog Laser

Epilog Laser MINI User manual

Epilog Laser

Epilog Laser Fusion User manual

Epilog Laser

Epilog Laser Fusion Use and care manual

Epilog Laser

Epilog Laser Fusion M2 32 User manual

Epilog Laser

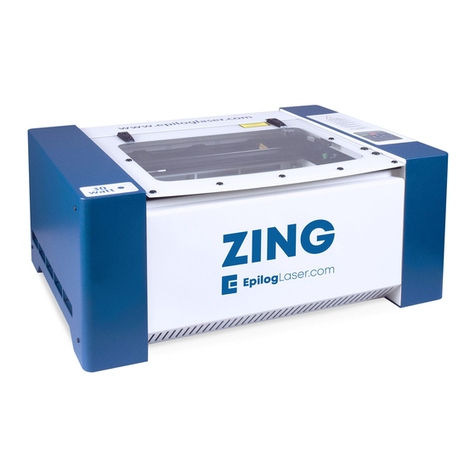

Epilog Laser Zing User manual

Epilog Laser

Epilog Laser Fusion Pro 32 User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser FusionPro 16000 User manual

Epilog Laser

Epilog Laser Fusion Pro 32 User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser Mini Series User manual

Epilog Laser

Epilog Laser Fusion User manual

Epilog Laser

Epilog Laser Fusion Pro 32 User manual

Epilog Laser

Epilog Laser MINI User manual

Epilog Laser

Epilog Laser Fusion User manual

Epilog Laser

Epilog Laser Zing User manual

Epilog Laser

Epilog Laser Helix User manual

Epilog Laser

Epilog Laser Fusion Use and care manual