EVCO S.p.A. Vcolor 579/589 | Installer manual ver. 1.0 | Code 144VC579E104

page

3

of

2

Contents

1

INTRODUCTION ................................................... 4

1.1

Introduction 4

1.2

Models available and main features 5

2

MEASUREMENTS AND INSTALLATION ..................... 8

2.1

Format features 8

2.2

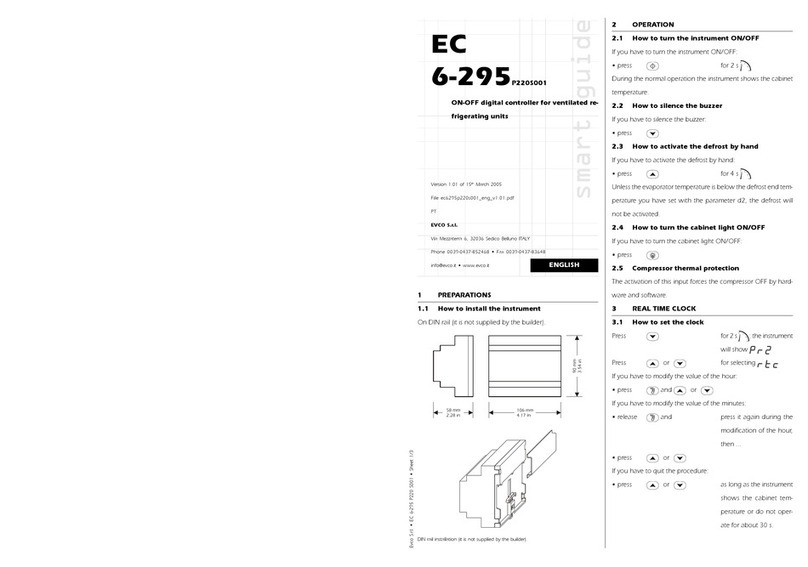

Control module measurements and installation 8

2.3

User interface measurements 8

2.4

User interface installation 9

2.5

EVC20P52N9XXX10 – EVC20P52N9XXX12 expansion

module measurements and installation 10

2.

Installation precautions 10

3

ELECTRICAL CONNECTION .................................. 11

3.1

Vcolor 579/589 M electrical connection 11

3.2

Vcolor 579/589 L electrical connection 12

3.3

Precautions for electrical connection 13

4

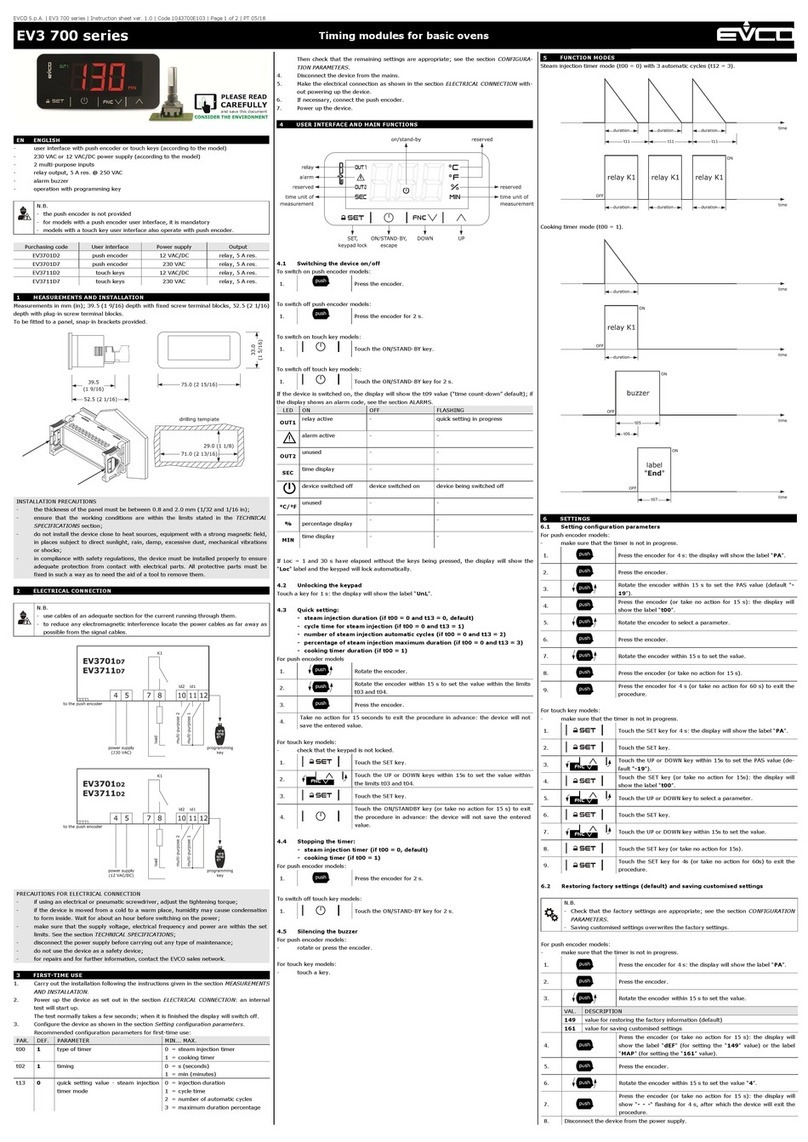

AGING AND/OR MEAT DRY-AGING OPERATION ..... 14

4.1

Initial information 14

5

FIRST-TIME USE ................................................ 14

5.1

Operating modes 14

5.2

Operating the device 14

NAVIGATION ..................................................... 1

.1

Initial information 1

.2

Stand-by screen 1

.2.1

Meat dry-aging configuration 1

.2.2

Aging configuration 1

.2.3

Combined configuration 1

.3

Cycle run screen 17

.3.1

Regulator status icons 17

.3.2

Function keys 18

.4

Screen saver 18

.5

Settings screen 18

.5.1

Switch-off 19

.5.2

Manual defrost19

.5.3

Alarms 19

.5.4

Internal values 20

.5.5

Counters 20

.5.

General settings 20

.5.7

Service 21

.5.8

Advanced 22

.

User management 23

7

MAIN FUNCTIONS .............................................. 24

7.1

Meat dry-aging cycle 24

7.2

Aging cycle 25

7.2.1

Selecting, changing and starting up a recipe 25

7.2.2

Adding/Removing a phase 27

7.3

Special functions 27

7.3.1

Air exchange management 28

7.3.2

Management of product rest intervals 29

7.3.3

Management of smoking cycles 29

7.3.4

Management of sanitation cycles 29

7.4

Recipe book 29

8

REGULATIONS ................................................... 31

8.1

Temperature regulation 31

8.1.1

Generating cooling 31

8.1.2

Generating heat 31

8.2

Humidity regulation 31

8.2.1

Humidification management 31

8.2.2

Dehumidification management 32

9

LOAD MANAGEMENT ........................................... 33

9.1

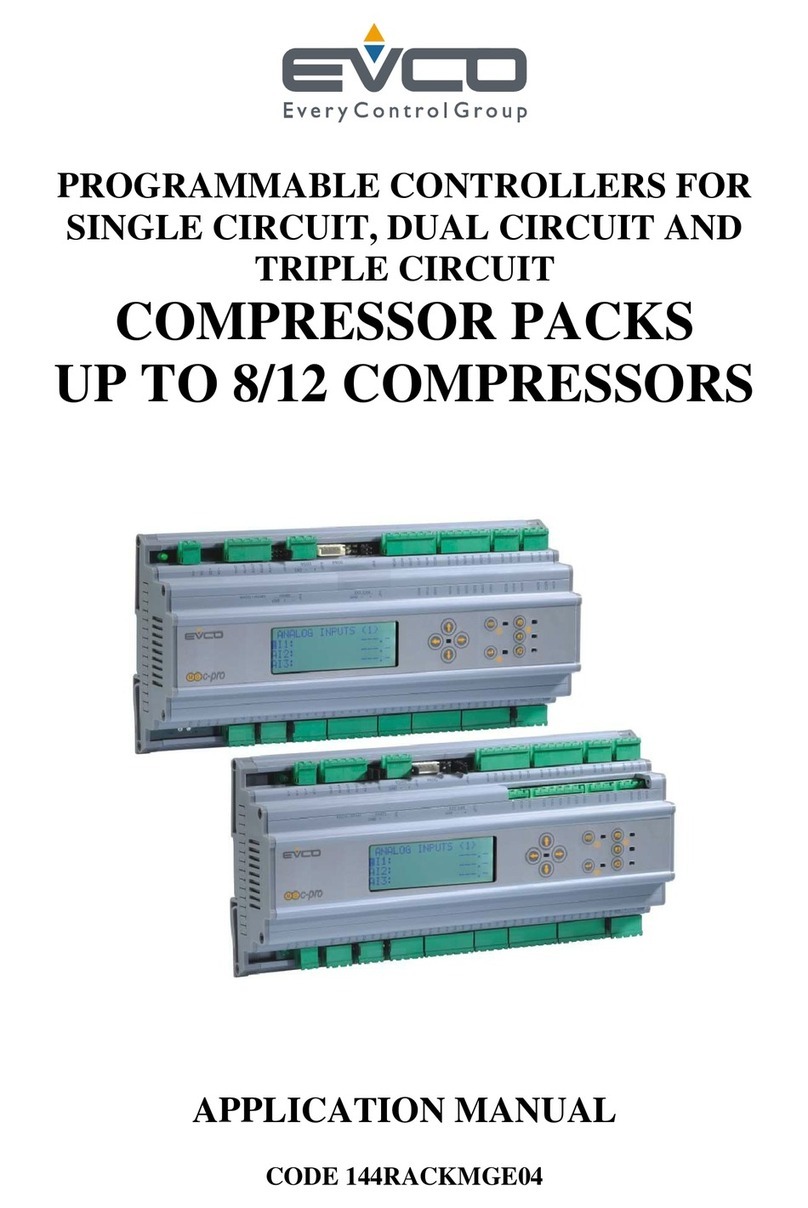

ON-OFF / variable speed compressor management 33

9.2

Pump-down management 33

9.3

Evaporator fan management 33

9.3.1

EVDFAN1 module management (only for the Vcolor

579 version with PWM): 34

9.3.2

Management by EVCO inverter 34

9.4

Defrost management 34

9.5

Heater management 34

9.

Steam generator output management 34

9.7

Humidifier output management 35

9.7.1

Humidifier output management without a probe 35

9.7.2

Humidifier output management with a probe (with

E =0) 35

9.7.3

Humidifier output management with a probe (with E =

1) 35

9.8

Dehumidification management 35

9.8.1

Extractor fan/dehumidifier management 35

9.8.2

Management by activating the refrigeration plant 35

9.9

Condenser fan management 3

9.10

Cabinet light management 3

9.11

On/Stand-by output management 3

9.12

Output testing 3

9.13

Testing cycle 3

10

CONNECTIVITY .................................................. 38

10.1

Initial information 38

10.2

EPoCA cloud platform 39

11

USB PORT MANAGEMENT .................................... 40

11.1

Available functions 40

12

ALARMS ............................................................ 41

12.1

Active alarms 41

12.2

List of alarms 42

13

PARAMETERS..................................................... 45

14

ACCESSORIES ................................................... 55

14.1

4 relay expansion 55

14.2

Phase cutting speed regulator 55

14.3

EVCO Inverter 55

14.4

Safety transformer 5

14.5

Non-optoisolated RS-485/USB serial interface 5

14.

USB plug for panel installation 5

14.7

Connecting cables 5

14.8

4GB USB flash drive 5

14.9

EVlinking Wi-Fi RS-485 module 57

14.10

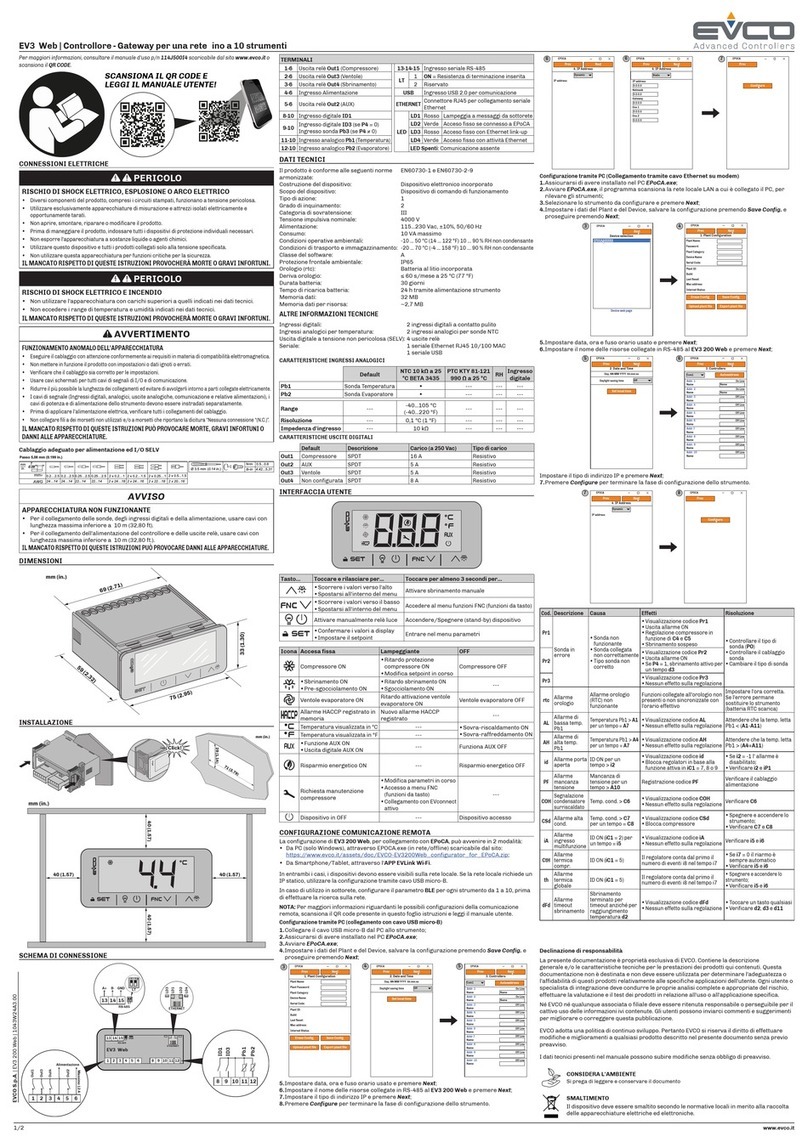

IoT EV3 Web gateway 57

14.11

Humidity transducer 4÷20 mA 57

15

TECHNICAL SPECIFICATIONS .............................. 58

15.1

Technical data 58