2

TABLE OF CONTENTS

B680H BARRIER GATE OPERATOR

1. TECHNICAL SPECIFICATIONS ............................................................................................................................................................6

2. ELECTRICAL LAYOUT .........................................................................................................................................................................7

3. DIMENSIONS .........................................................................................................................................................................................7

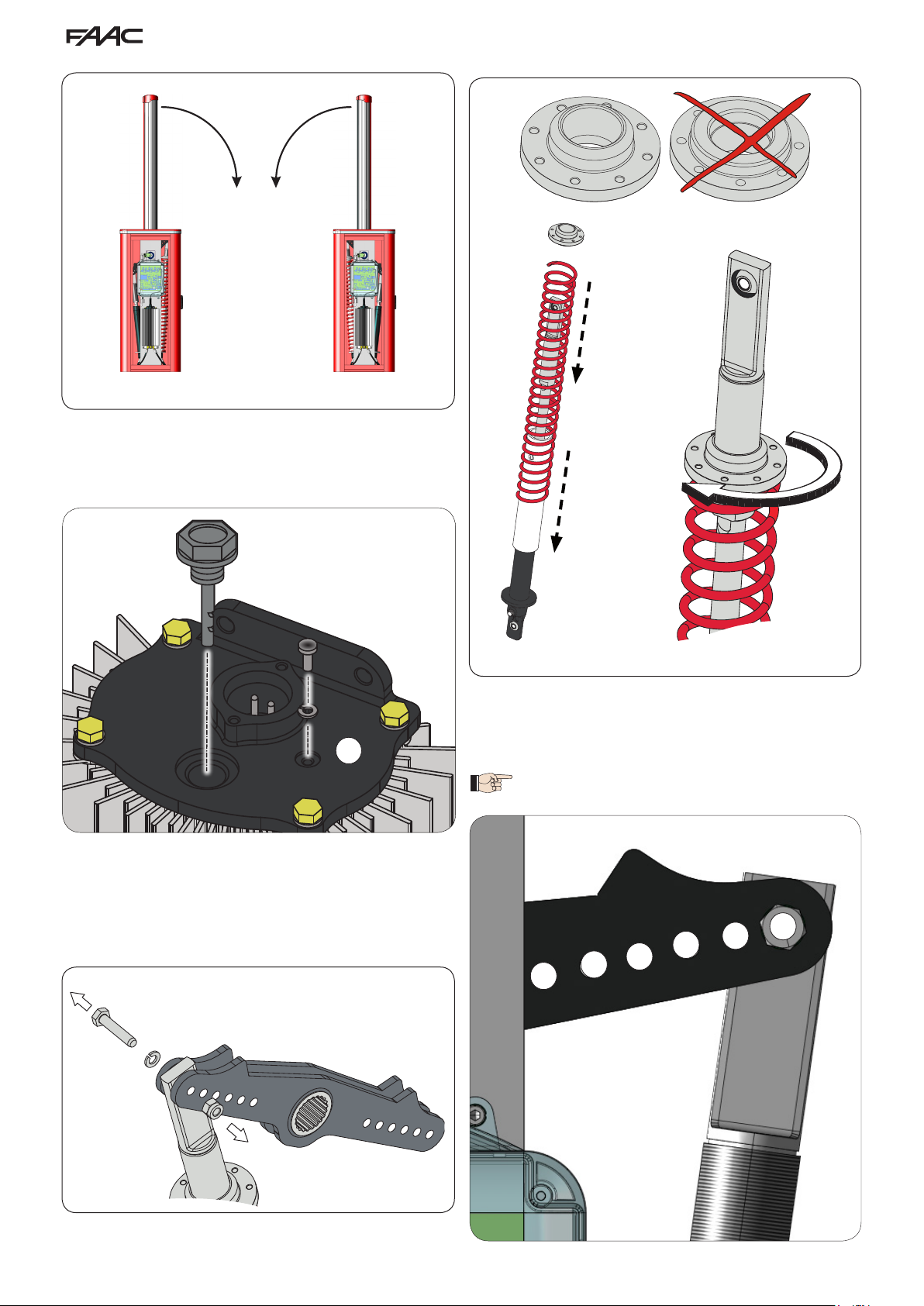

4. INSTALLING THE OPERATOR..............................................................................................................................................................7

4.1 Preliminary checks .......................................................................................................................................................................7

4.2 Install the foundation plate..........................................................................................................................................................7

4.3 Mechanical installation ................................................................................................................................................................7

4.5 Balancing the Beam....................................................................................................................................................................12

5. MANUAL OPERATION ........................................................................................................................................................................12

5.1 Restore normal operations ........................................................................................................................................................12

6. POWER CONNECTION .......................................................................................................................................................................12

7. FIELD INSTALL LABELS ....................................................................................................................................................................13

8. REVERSING THE OPENING DIRECTION ..........................................................................................................................................13

9. MAINTENANCE ...................................................................................................................................................................................13

8.1 Topping up the oil .......................................................................................................................................................................13

8.2 Air bleeding .................................................................................................................................................................................13

10. INSTALL THE BEAM LIGHTS ...........................................................................................................................................................14

11. INSTALL THE COVER .......................................................................................................................................................................15

12. SPARE PARTS ...................................................................................................................................................................................16

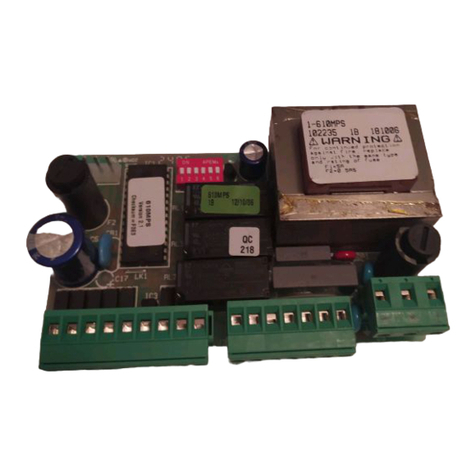

E680 CONTROL BOARD

1. WARNINGS ..........................................................................................................................................................................................18

2. DESCRIPTION OF THE COMPONENTS ............................................................................................................................................18

3. TECHNICAL SPECIFICATIONS ..........................................................................................................................................................18

4. ELECTRICAL CONNECTIONS............................................................................................................................................................19

4.1 Terminal board J1 (inputs) .........................................................................................................................................................19

4.2 Terminal board J2 (outputs).......................................................................................................................................................20

4.3 Terminal board J3 (external ashing lamp) .............................................................................................................................20

4.4 Terminal board J4 (loop detector) ............................................................................................................................................20

4.5 Connector J5 (Motor)..................................................................................................................................................................20

4.6 Connector J7 (Encoder).............................................................................................................................................................20

4.7 Connector J10 (Radio)................................................................................................................................................................20

4.8 Connector J11 (Beam break-out sensor) .................................................................................................................................20

4.9 Connector J12 (Emergency battery).........................................................................................................................................20

4.10 Connector J13 (36VDC Power Supply) ...................................................................................................................................20

4.11 Connector J15 (ashing trac light) ......................................................................................................................................20

4.12 Connector J16 (beam lights)....................................................................................................................................................21

5. PROGRAMMING..................................................................................................................................................................................21

5.1 Basic conguration.....................................................................................................................................................................21

5.2 Changing the predened parameters set ................................................................................................................................22

5.3 Default Selection Tables ............................................................................................................................................................23

6. Advanced Conguration ....................................................................................................................................................................24

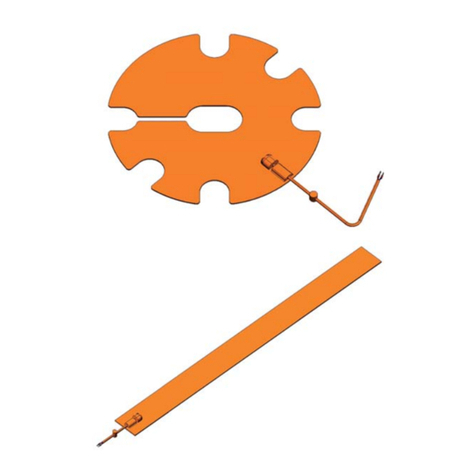

6.1 Conguring the loop detector ...................................................................................................................................................25

6.2 Expert Conguration ..................................................................................................................................................................26

6.3 Pre-Dened Parameter Sets......................................................................................................................................................29

6.4 “Expert” default parameters .....................................................................................................................................................30

7. START-UP.............................................................................................................................................................................................30

7.1 Verifying the diagnostic LEDs ...................................................................................................................................................30

7.2 Setup.............................................................................................................................................................................................30

8. TESTING THE AUTOMATED SYSTEM ...............................................................................................................................................30

9. MASTER/SLAVE CONFIGURATION ...................................................................................................................................................31

10. INTERLOCK .......................................................................................................................................................................................32

11. OPERATING LOGICS TABLE............................................................................................................................................................33

B680H Rev. A October 2016