Page 7

Rev. 01.2006 - Istallation Manual

Terminals “14-18” (OPEN A-COM1): Normally open contact.Connect, to these terminals,any pulse generator

(e.g.push-button, key selector,etc..) which, by closing a contact,generates a pulse for totally opening or

closing the gate. The operation of this input is defined by dip-switch 3 - see paragraph 2.5.1.

Terminals “15-18” (OPEN B-COM1): Normally open contact. Connect, to these terminals, any pulse generator

(e.g. push-button, key selector, etc..) which, by closing a contact, generates a pulse for partially opening

the gate.

In two-motor installations (Dip-switch 5=ON); partial opening corresponds to the total opening of the leaf

on which the motor M1 is installed.

In single-motor applications (Dip-switch 5=OFF), partial opening coincides with an opening of about ~80%

of the total memory-stored opening.

If a total opening command (OPEN A) is given during the partial opening stage, the control unit memory

stores the command, which is executed when partial opening has finished.

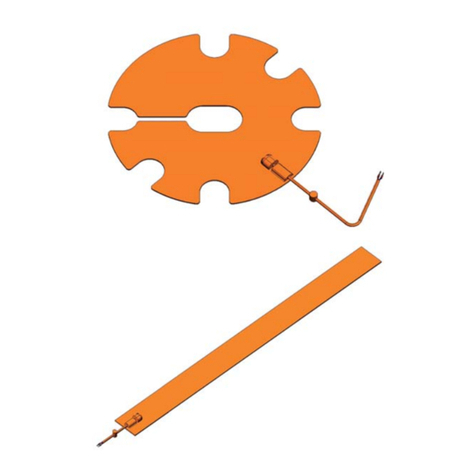

Terminals “16-18” (FSW-COM1): Normally closed contact. Connect, to these terminals, any safety device

(photocell, pressure switch, safety edge etc..) which, by opening a contact, affects the gate's closing

motion, reversing it to the mechanical opening stop, without disabling automatic re-closure if it is enabled.

The status of this input is signalled by LED "FSW".

This contact can be disabled with dip-switch 6 - see paragraph 2.5.1.

If you decide to disable the photocells, you do not have to jumper the input.

The control unit is supplied with the photocell input disabled.

Terminals “17-18” (STOP-COM1): Normally closed contact. Connect, to these terminals, any pulse generator

(push-button, key selector, etc..) which, by opening a contact, immediately stops the gate and disables all

automatic functions. The status of this input is signalled by the "STOP"LED. The gate resumes its memory-

stored cycle only by means of another total or partial opening pulse.

This contact can be disabled with dip-switch 7 - see paragraph 2.5.1.

If you decide to disable the stop command, you do not have to jumper the input.

The control unit is supplied with the stop command input disabled.

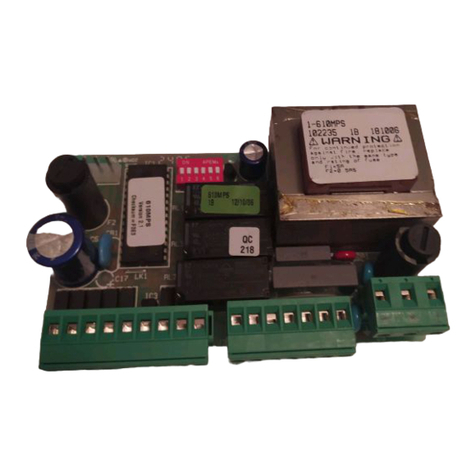

TERMINAL BOARD CN4

5-terminal connector for coupling receiver.

DIP-SWITCH

DP1(SW1): Parameter adjustment, see paragraph 2.5.1.

FUSES

F1: 16A T 250V 5X20.

F2: 10A T 250V 5X20.

LEDS ON OFF

POWER: Control unit fed by transformer No power supplied, or control unit fed by

batteries.

FSW: Safety device disengaged or input disabled. Safety device engaged, contact open.

STOP: Command inactive or input disabled. Command active, contact open.

Indicated in bold: status of LEDs with the gate closed, and control unit fed by transformer.

2.2.3 POWER SUPPLY CONNECTION

As concerns power supply:

1Use a 3 x 15 mm2 cable for conveying the 230V mains current, protected by a fuse or by a 10 Amp

circuit breaker, routing from the dwelling to the gate.