Translation of the original instructions ENGLISH

CONTENTS

1. BOLLARD J355HA M50 ........................................... 4

1.1 General instructions.............................................. 4

1.2 Technical descriptions and specifications...................... 4

1.3 Dimensions........................................................ 5

2. INSTALLATION ..................................................... 6

2.1 Configuration ..................................................... 6

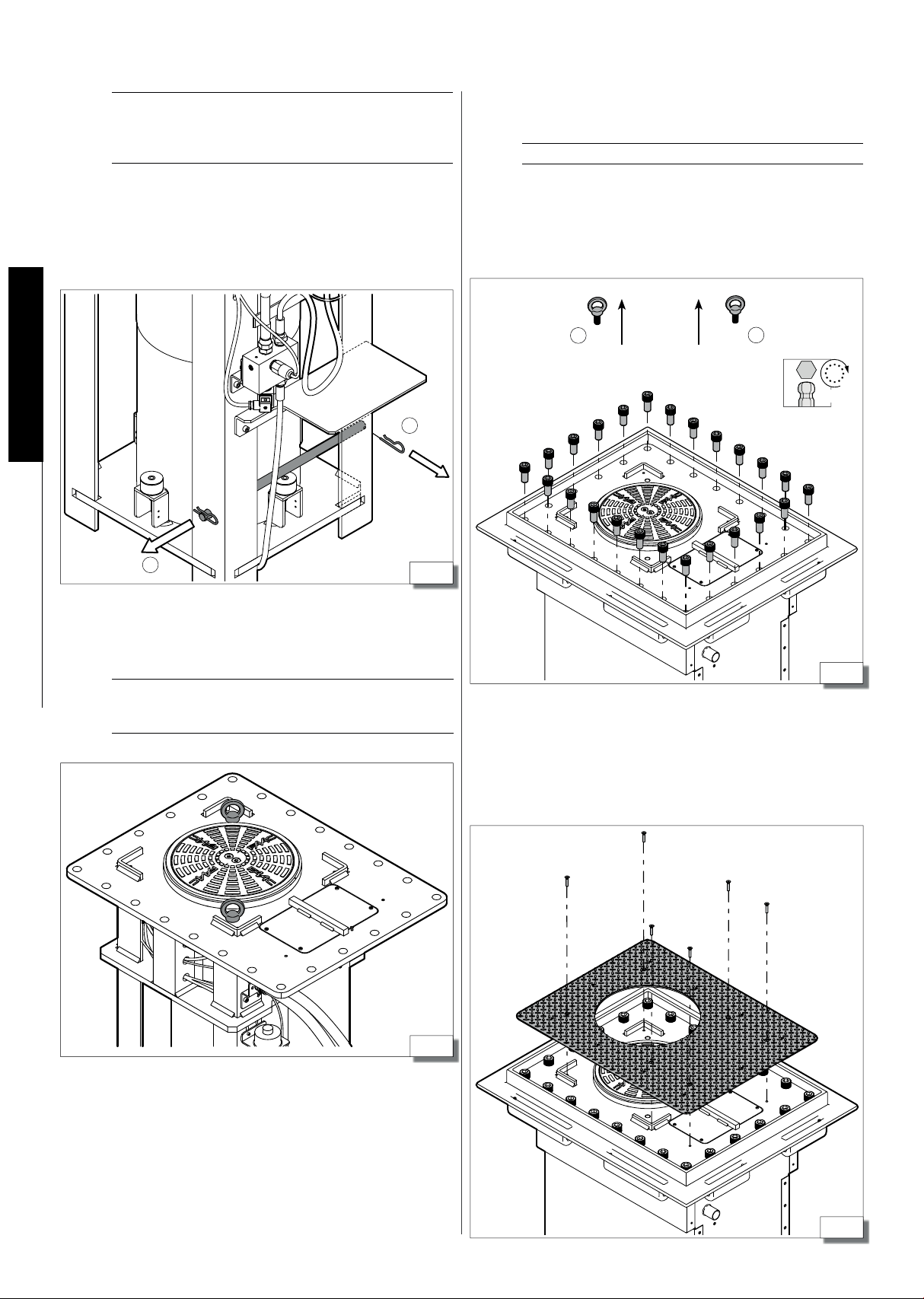

2.2 Construction of the foundation cage .......................... 7

2.3 Fixing the pit in place ............................................ 8

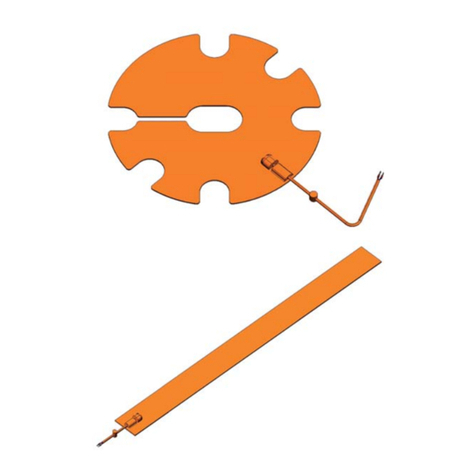

2.4 Electrical wiring..................................................10

2.5 Insertion into the pit ............................................11

2.6 Fixing the top cover .............................................11

2.7 EFO (Emergency Fast Operation - optional) ..................12

2.8 Manual operation (optional) ...................................12

2.9 Automatic operation ............................................12

2.10 Maintenance....................................................12

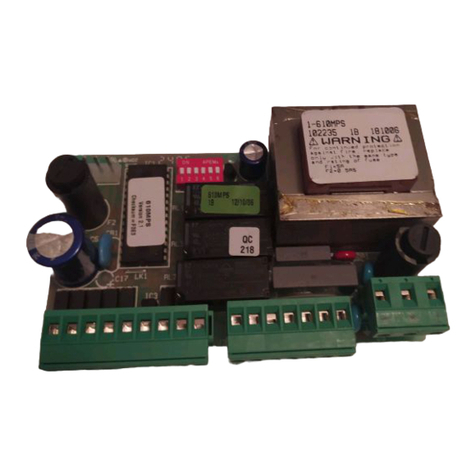

3. ELECTRONIC DEVICE JE275.................................... 13

3.1 Electrical connections ...........................................13

3.2 board programming ............................................14

3.3 Troubleshooting .................................................14

3.4 Connecting several bollards (master/slave) ..................15

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1. WARNING!The following instructions must be read and followed in full in order

to ensure the security and safety of individuals. Incorrect installation and/or

incorrect use of the product could cause serious harm to people.

2. Read the instructions carefully before attempting to install the product.

3. The packaging materials (plastic, polystyrene, etc.) must not be left within

reach of children as they are potential sources of danger.

4. Keep these instructions for future reference.

5. This product has been designed and built strictly for the use indicated in

this documentation. Any other use that is not expressly specified in these

instructions could affect the integrity of the product and/or represent a

source of danger.

6. FAAC declines all liability deriving from misuse or any use other than that for

which the automated system is intended.

7. Do not install the equipment in an explosive atmosphere: the presence of

flammable gas or fumes represents a serious safety hazard.

8. FAAC is not responsible for failure to observe the rules of good technical

practice during construction of motorised gates or closure devices, or for any

damage which occurs during use of these.

9. Installation must be performed in compliance with Standards currently in

force.

10. Before performing any operation on the system, disconnect the power supply.

11. The power mains of the automation system must be fitted with a multi-pole

power switch with a switch-contact gap of at least 3 mm. It is advisable to

use a 6A circuit breaker with a multi-pole power switch.

12. Ensure there is a residual current device with a 0.03 A threshold upstream

of the system.

13. Check that the earthing system is constructed in accordance with the highest

standards of workmanship and connect this to the metal parts of the gate.

14. The automated system is equipped with a built-in anti-crushing system

consisting of a torque control device. It is nonetheless necessary to check

the activation threshold, in accordance with the rules set out in point 10.

15. The safety devices (pursuant to standard EN 12978) protect any potentially

dangerous areas against mechanical movement risks, such as crushing, drag-

ging, shearing and lifting.

16. For each system, operators are advised to install at least one flashing light

(e.g. integrated into the bollard head), as well as an adequately secured

warning sign.

17. FAAC cannot be held responsible for any issue regarding the safety and cor-

rect operation of the device in any case in which components not produced

by FAAC are used.

18. For maintenance, only original parts manufactured by FAAC must be used.

19. Do not modify the components of the automation system in any way.

20. The installer must supply all information relating to the manual operation of

the system in case of emergency to the user.

21. Do not allow children or adults to remain near the product during operation.

22. Keep all remote controls or any other pulse generator out of the reach of

children, to prevent the automated system from being activated involuntarily.

23. The bollard must only be crossed when the device is fully lowered.

24. The user must not attempt any kind of repair or any other form of direct

operation on the device, and must only contact qualified personnel in order

to do this.

25. Anything else not expressly specified in these instructions is not permitted.