J275 HA 2K20 3 532270 - Rev.A

Translation of the original instructions ENGLISH

EU DECLARATION OF CONFORMITY

The Manufacturer

Company name: FAAC S.p.A. Soc. Unipersonale

Address: Via Calari, 10 - 40069 Zola Predosa - BOLOGNA - ITALY

hereby declares on his sole responsibility that the following products:

Description: Automatic retractable bollard

Model: J275 HA 2K20

comply with the following applicable EU legislations:

2014/30/EU/EU

2011/65/EU/EU

Furthermore, the following harmonised standards have been applied:

EN61000-6-2:2005

EN61000-6-3:2007 + A1:2011

Bologna, Italy, 11-01-2020 CEO

TABLES

1 Symbols: notes and warnings on the instructions ........ 4

2 Technical data ................................................. 8

3 Troubleshooting .............................................16

4 Routine maintenance........................................18

CONTENTS

EU Declaration of conformity................................... 3

EU Declaration of conformity................................... 3

1. INTRODUCTION TO THE INSTRUCTION MANUAL........... 4

1.1 Meaning of the symbols used................................... 4

2. SAFETY RECOMMENDATIONS .................................. 5

2.1 Installer safety .................................................... 5

2.2 Storing the product .............................................. 5

2.3 Disposing of the product ........................................ 5

3. J275 HA 2K20 ....................................................... 6

3.1 Intended use ...................................................... 6

3.2 Limitations of use................................................. 6

3.3 Unauthorised use................................................. 6

3.4 Emergency use.................................................... 6

3.5 Product identification ............................................ 6

3.6 Technical characteristics ......................................... 7

3.7 Component identification ....................................... 7

Installation accessories (supplied separately) ................ 7

Optional Accessories ............................................ 8

3.8 Dimensional drawing ............................................ 8

4. INSTALLATION REQUIREMENTS................................ 9

4.1 Mechanical requirements........................................ 9

4.2 Electrical system .................................................. 9

5. INSTALLATION ................................................... 10

5.1 Installing the bollard ............................................10

5.2 Manual operation................................................11

Release procedure.............................................. 11

Restoring automatic operation ...............................12

5.3 Connections......................................................13

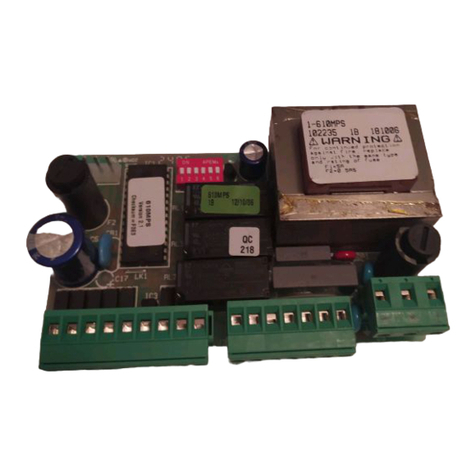

5.4 Board programming.............................................14

5.5 Connecting multiple bollards ..................................14

5.6 Troubleshooting .................................................16

6. MAINTENANCE................................................... 17

6.1 Removing the hydraulic unit ...................................17

6.2 Topping up the oil level .........................................18

6.3 Bleeding the system.............................................18

6.4 Routine maintenance ...........................................18

7. INSTALLING OPTIONAL EQUIPMENT........................ 19

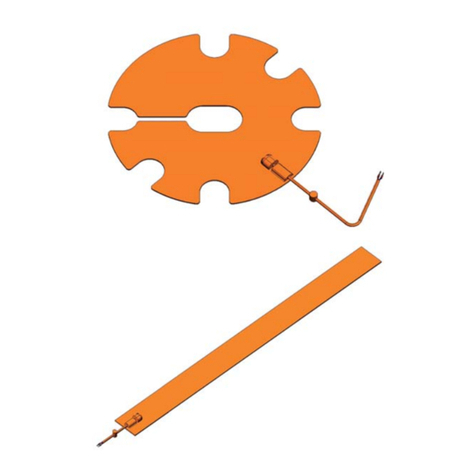

7.1 Installing the pressure switch ..................................19

Multiple connections...........................................19

7.2 Installing the solenoid valve....................................20

Connecting the control coil....................................20

Multiple connections...........................................21

7.3 Cover ..............................................................21

A. Marcellan

EU DECLARATION OF CONFORMITY

The Manufacturer

Company name: FAAC S.p.A. Soc. Unipersonale

Address: Via Calari, 10 - 40069 Zola Predosa - BOLOGNA - ITALY

hereby declares on his sole responsibility that the following products:

Description: Automatic retractable bollard

Model: J275 HA 2K20

comply with the following applicable EU legislations:

2014/30/EU

2011/65/EU

Furthermore, the following harmonised standards have been applied:

EN61000-6-2:2005

EN61000-6-3:2007 + A1:2011

Bologna, Italy, 26-11-2020 CEO

A. Marcellan

DECLARATION OF INCORPORATION FOR PARTLY

COMPLETED MACHINERY

(2006/42/EC ALL.II P.1, LETT. B)

Manufacturerand person authorisedtopreparethe relevanttechnicaldocumentation

Company name: FAAC S.p.A. Soc. Unipersonale

Address: Via Calari, 10 - 40069 Zola Predosa - BOLOGNA - ITALY

hereby declares that for the partly completed machinery:

Description: Automatic retractable bollard

Model: J275 HA 2K20

The essential requirements of the Machinery Directive 2006/42/EC (including

all applicable amendments) that have been applied and fulfilled are as follows:

1.1.2, 1.1.3, 1.1.5, 1.3.1, 1.3.2, 1.3.4, 1.5.1, 1.5.3,

1.5.5,1.5.6, 1.5.7, 1.5.15, 1.6.1, 1.6.2, 1.6.3, 1.6.4, 1.7.1,

1.7.2, 1.7.3, 1.7.4.1, 1.7.4.2, 1.7.4.3

and that the relevant technical documentation has been compiled in compliance

with part B of Annex VII.

Furthermore, the following harmonised standards have been applied:

EN12100:2010

EN60335-1:2012+A11:2014+A13:2017

Andalso undertakestotransmit,in response to areasoned request by thenational au-

thorities, relevant information on the partly completed machinery by mail or e-mail.

Finally, the manufacturer declares that the above-mentioned partly completed

machinery must not be put into service until the final machine in which it is to be

incorporated has been declared compliant with the requirements of the above-

mentioned Machinery Directive 2006/42/EC.

Bologna, Italy

26-11-2020

CEO

A.Marcellan