B614 2 732998 - Rev.A_DRAFT

Translation of the original instructions ENGLISH

CONTENTS

EU Declaration of conformity......................................................1

Declaration of incorporation for partly completed machinery1

1. INTRODUCTION TO THIS INSTRUCTIONS MANUAL......4

1.1 Meaning of the symbols used.................................................4

2. SAFETY RECOMMENDATIONS..............................................6

2.1 Installer safety ..........................................................................6

2.2 Transport and storage..............................................................7

2.3 Unpacking and handling.........................................................8

2.4 Disposal of the product............................................................8

3. B614.............................................................................................9

3.1 Intended use .............................................................................9

3.2 Limitations of use.....................................................................9

3.3 Unauthorised use .....................................................................9

3.4 Emergency use........................................................................10

3.5 Product identification............................................................10

3.6 Technical specifications..........................................................10

3.7 Manual operation...................................................................11

Release procedure......................................................................11

Operation restoration.................................................................11

3.8 Component identification .....................................................12

3.9 Installation components........................................................13

3.10 Optional accessories.............................................................13

4. INSTALLATION REQUIREMENTS.........................................14

4.1 Mechanical requirements......................................................14

4.2 Electrical system.....................................................................15

4.3 Example System......................................................................16

5. MECHANICAL INSTALLATION..............................................17

5.1 Tools required..........................................................................17

5.2 Placing the foundation plate................................................18

5.3 Installing the barrier body ....................................................19

Fixing the cables inside the barrier..........................................20

5.4 Fitting the beam.....................................................................21

Preparing the balancer..............................................................21

Rectangular beam......................................................................21

Round beam................................................................................23

5.5 Fitting the spring....................................................................25

Tie rod ..........................................................................................25

Single spring ...............................................................................26

Double spring..............................................................................26

5.6 Accessories on the beam .......................................................27

5.7 Balancing the beam...............................................................27

5.8 Limit switch adjustment........................................................28

5.9 Earthing the door ...................................................................29

5.10 Closing the door ...................................................................29

5.11 Closing the upper lid............................................................30

6. INSTALLING OPTIONAL FEATURES....................................31

6.1 Personalised key release........................................................31

7. ELECTRONIC INSTALLATION................................................32

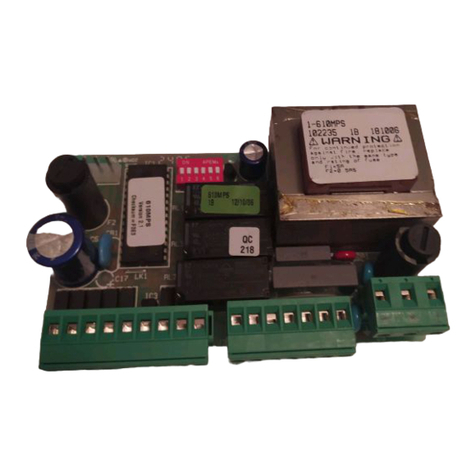

7.1 Board E614 ..............................................................................32

Components ...............................................................................32

7.2 Connections.............................................................................34

Control devices............................................................................34

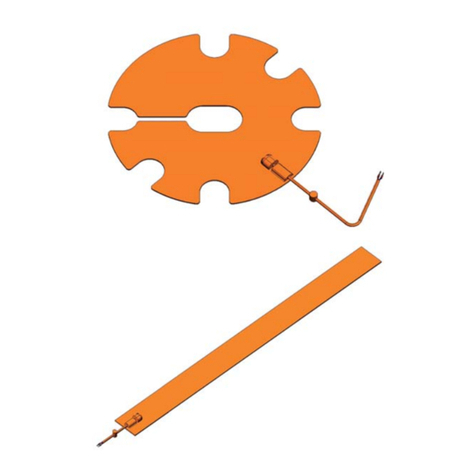

External loops .............................................................................35

Bus devices..................................................................................35

OUT outputs ................................................................................35

24 V "flashing light ................................................................35

Motor............................................................................................35

Encoder ........................................................................................35

Beam lights .................................................................................36

Integrated flashing light ...........................................................36

Battery XBAT 24 .........................................................................36

Radio module XF.........................................................................36

Mains supply and earthing ......................................................36

8. STARTUP...................................................................................37

8.1 Programming..........................................................................37

Basic programming....................................................................37

Advanced programming ...........................................................38

8.2 Operating logics......................................................................41

EP - Semi-automatic step by step...........................................41

A- Automatic..............................................................................41

AP - Automatic step-by-step ...................................................41

b- Semi-automatic b ................................................................41

bC- Semiautomatic bon opening/ person present Con

closure..........................................................................................41

C- Dead-man .............................................................................41

P- Carpark ...................................................................................41

8.3 SET-UP......................................................................................42

9. PUTTING INTO SERVICE ........................................................43

9.1 Final checks .............................................................................43

9.2 Final operations......................................................................43

10. ACCESSORIES..........................................................................44

10.1 24V FLASHING LIGHT "....................................................44

10.2 Emergency battery XBAT 24................................................44

10.3 Radio module XF ..................................................................45

SLH/SLH LR - Memorising the first remote control................45

SLH/SLH LR - Memorising other remote controls .................45

LC/RC - Memorising the first remote control..........................45