12

ENGLISH

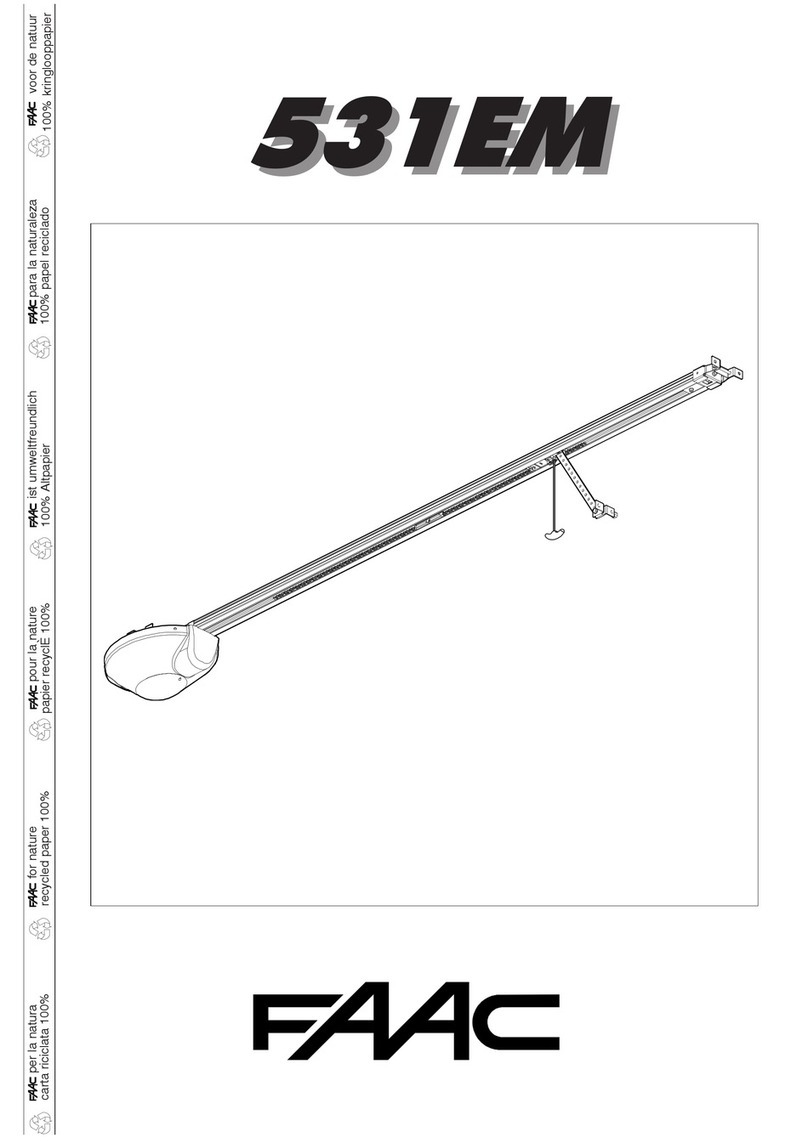

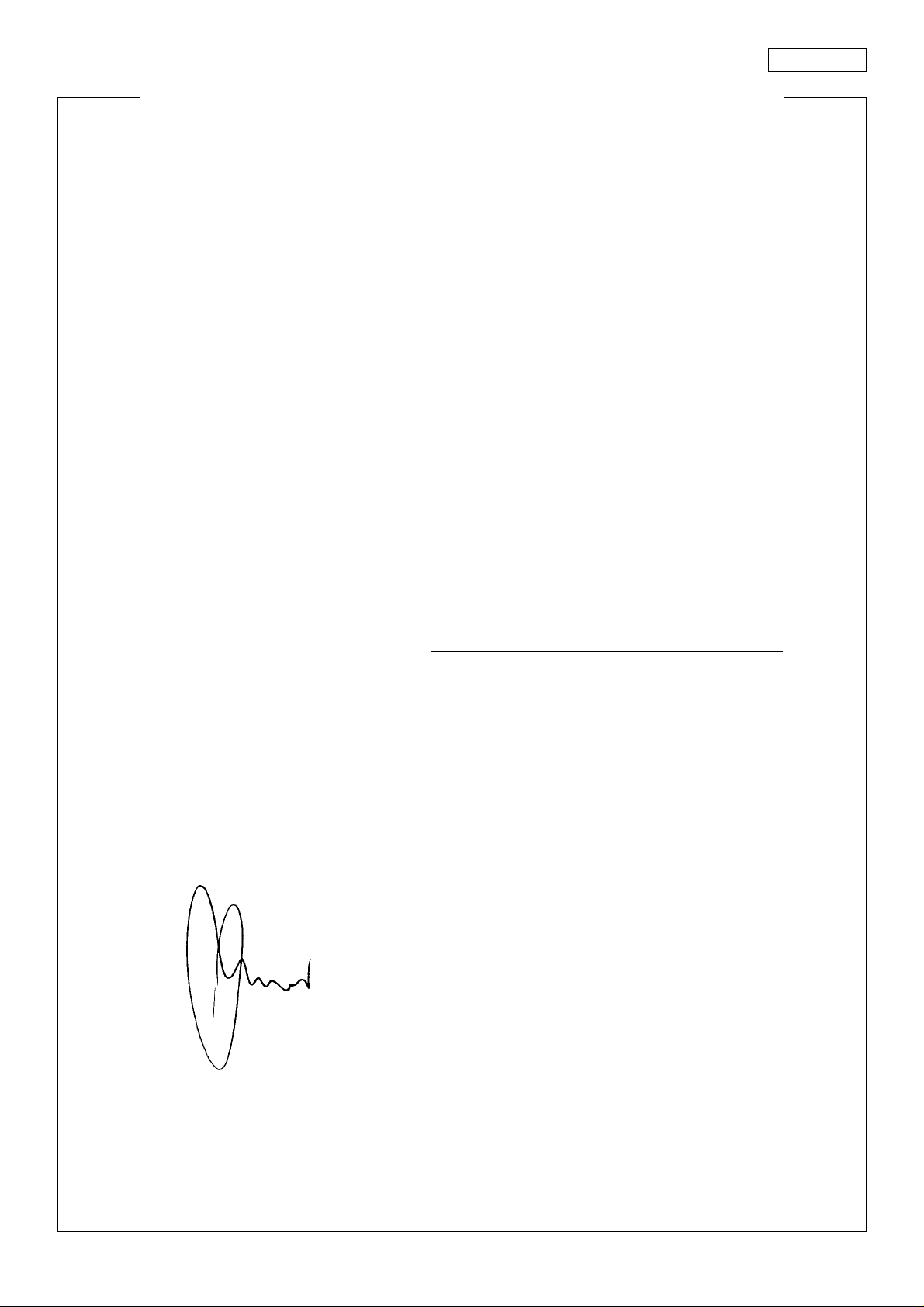

2. INSTALLATIONLAYOUT

• “Screw assembly”: all accessories feature screw-on

attachment.

Straight or curved telescopic arms are available for both

versions.

The present instructions refer to “screw assembly”.

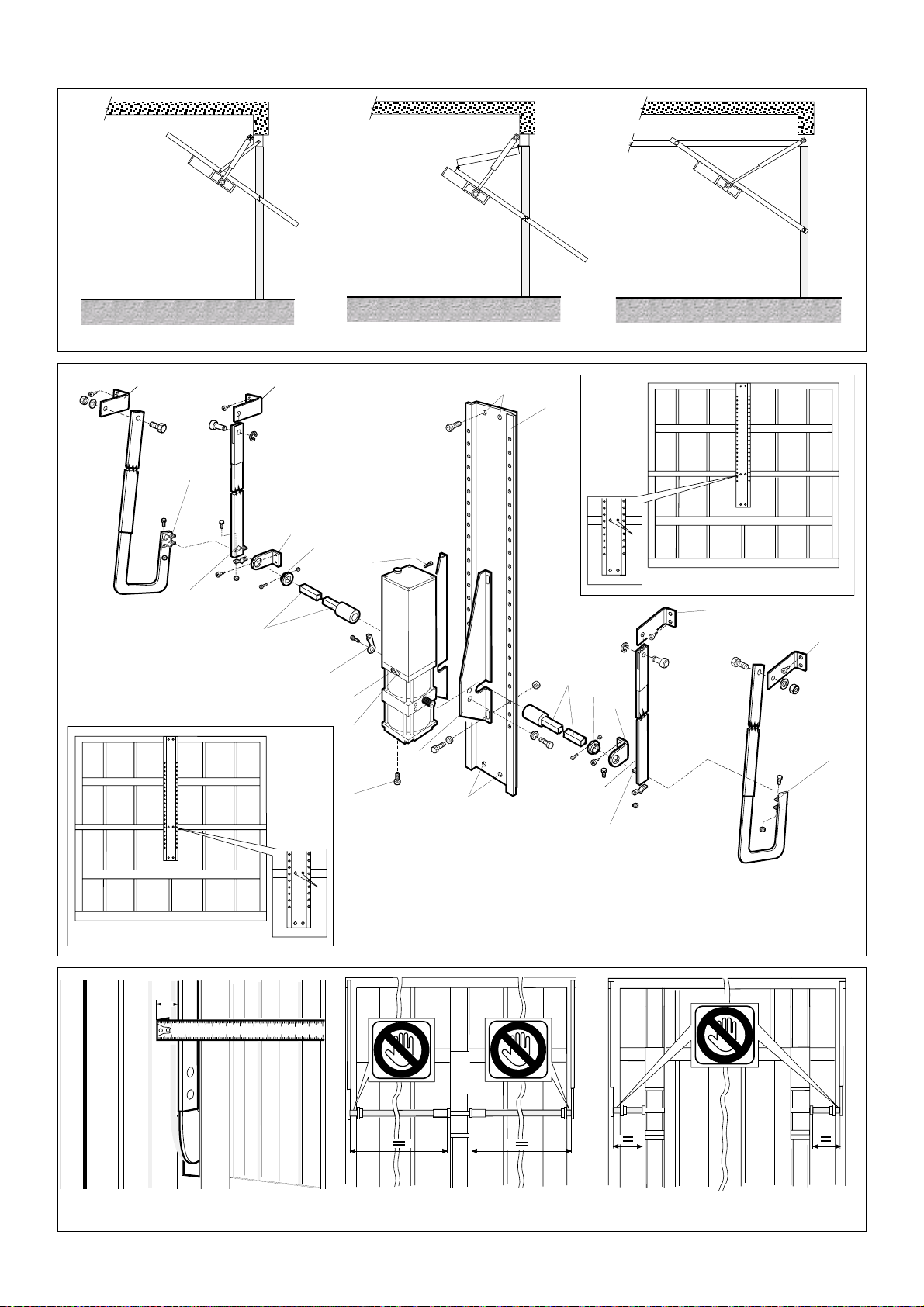

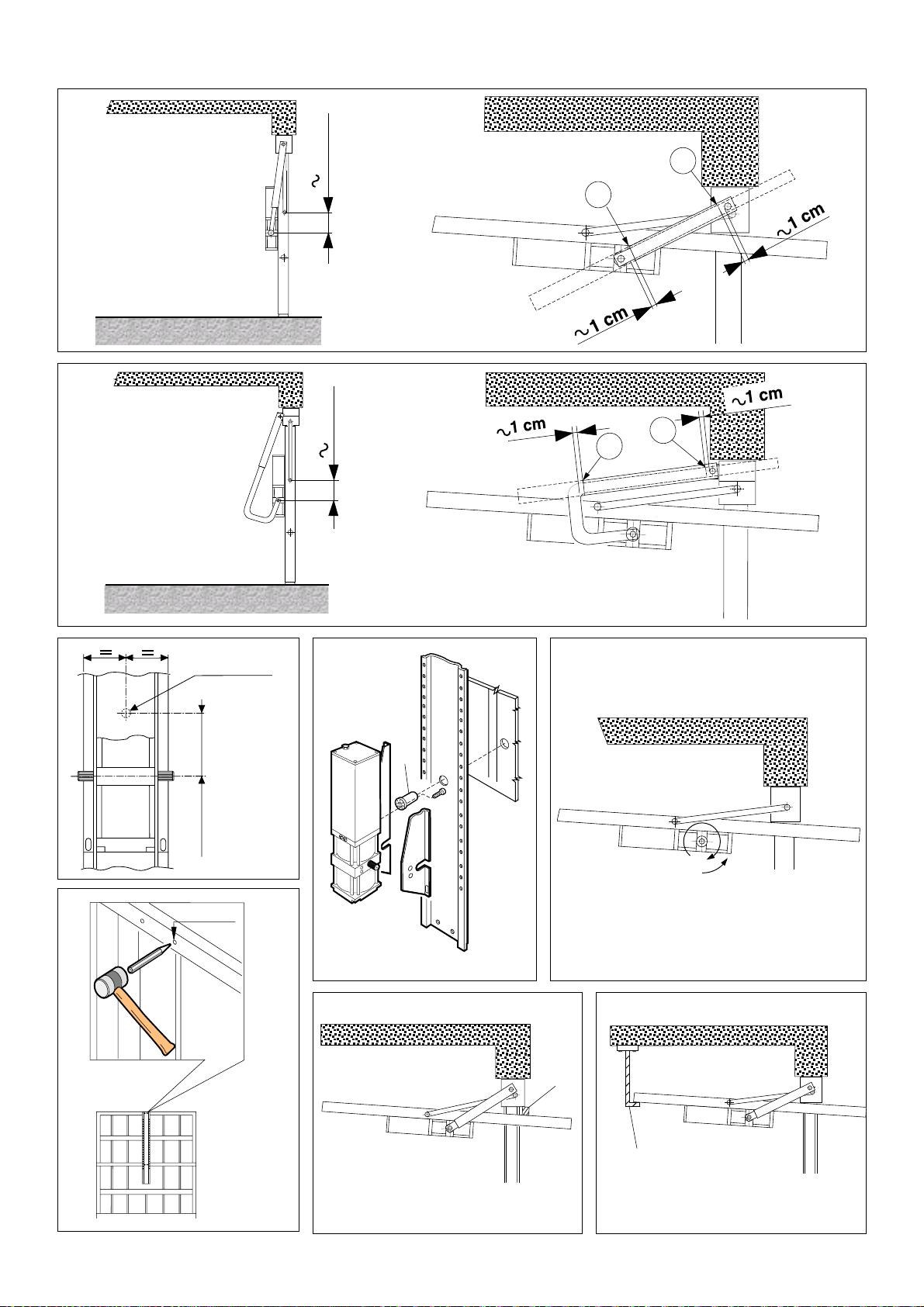

4.3. POSITIONING OF TELESCOPIC ARMS

Ensure that there is a gap (S - fig.5) of at least 15 mm

betweentheexistingcrossbarandtheframe.Thisisessential

if straight telescopic arms are to rotate correctly as shown

in fig.8.

If gap (S) is less than 15 mm, the special curved telescopic

arm must be used instead, and installed as shown in fig.9.

Refer to fig.4 to fix brackets (D) to the upright member as

close as possible to the upper support of the existing cross

bar. Fit the outer profiles of the arms. Respect maximum

door dimensions as per the technical specifications and

install either one operator (FAAC 593) at the centre of the

door (fig.6) or two operators at the sides of the door (fig.7).

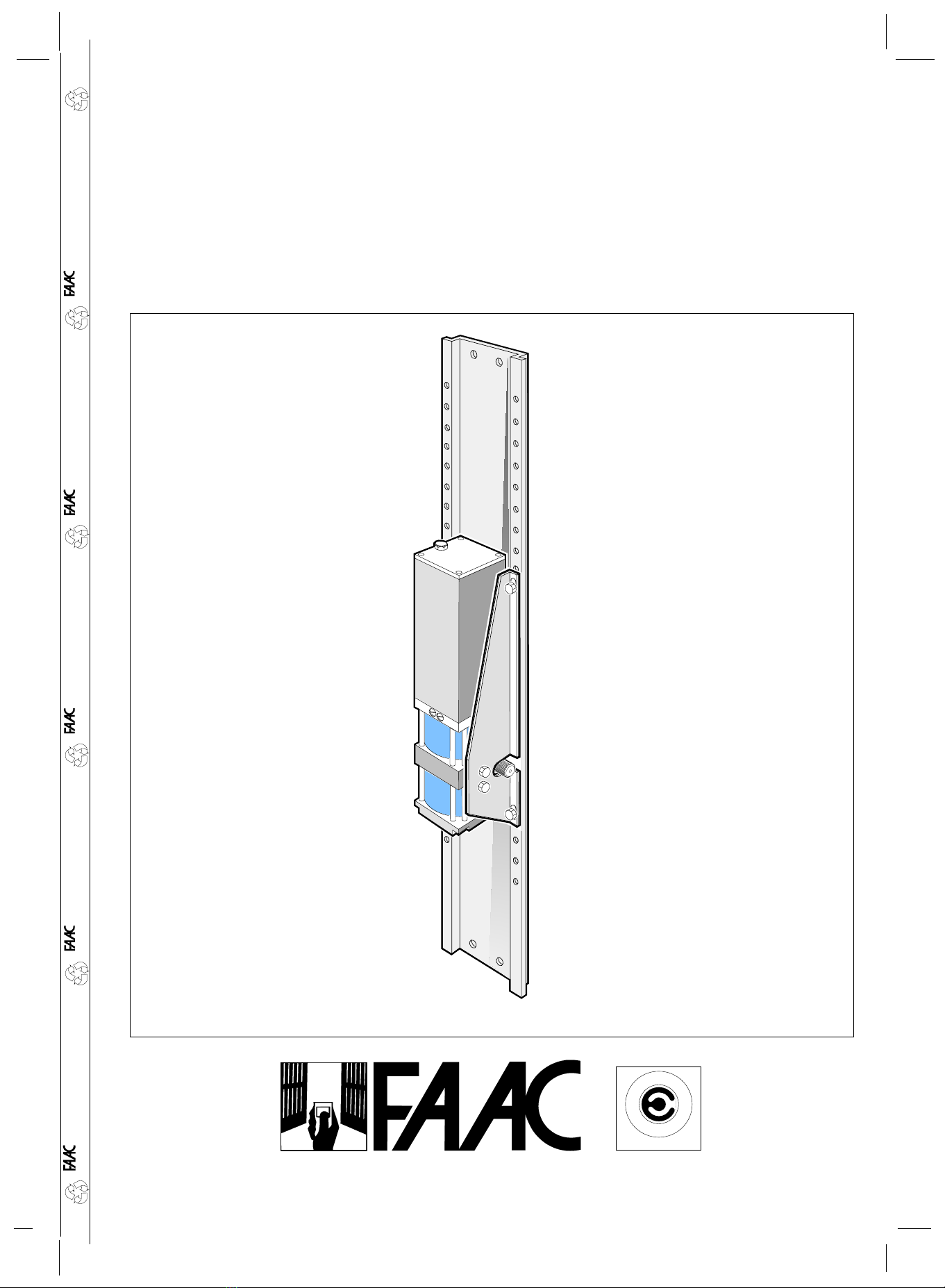

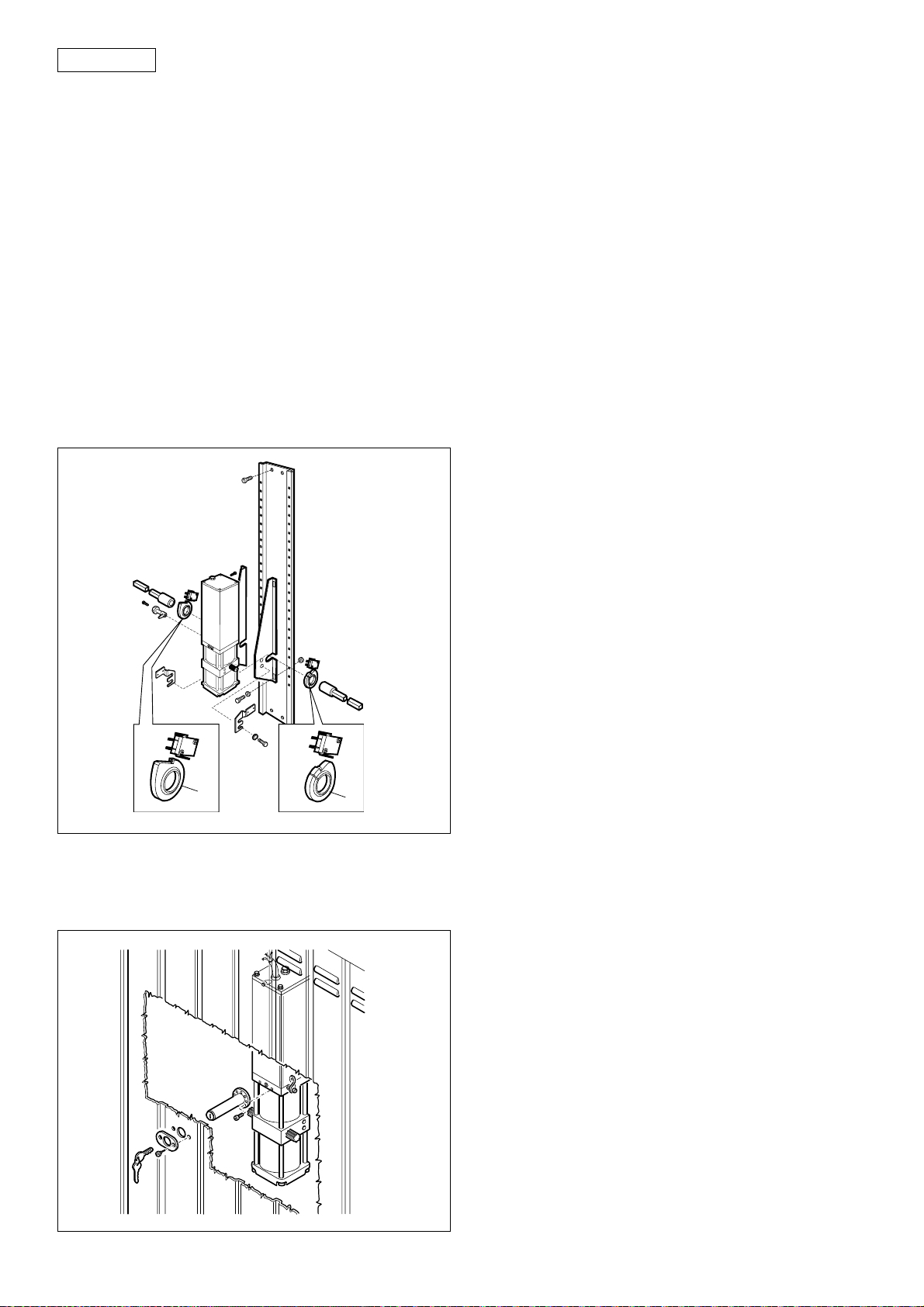

4.4. POSITIONING THE BACK PLATE / OPERATOR /

DRIVE SHAFTS

The back plate (Z) features two holes (M) and (N) which

allow for fixture to the upper cross bar of the door as

indicated in Aand Bof fig.4.

In the case of door heights of less than 2100 mm, fit the

backplate on the upper cross bar by means of (M) (see A).

With door heights above 2100 mm, fit the backplate by

means of (N) (see B, fig.4).

Drill two 6 mm holes (U) for backplate fixture onto the

centralreinforcementribbing of the door(fig.4).If the door

frameisnotsufficientlysturdy(thinsheet)usenutsandbolts.

Alternatively, use self-tapping screws.

Locate the point of rotation of the drive shaft at 10 cm

below the bottom pivot of the door’s own arm as shown in

figs. 8 and 9.

Removebleedscrew(F)andsecuretheoperatorbymeans

ofmountingbrackets(S)onthebackplateasshowninfig.4.

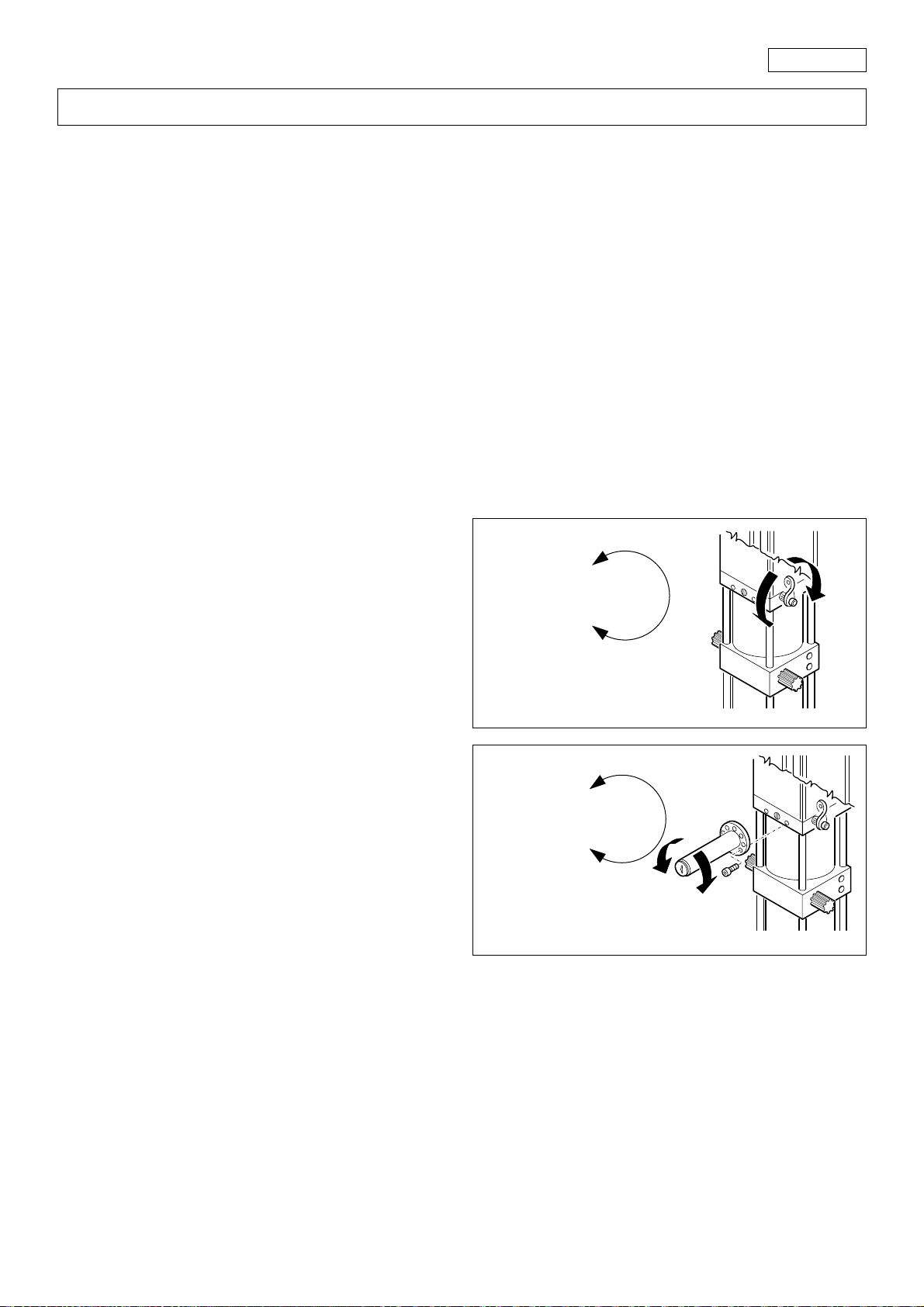

Disconnect the operator and open the garage door as

indicated in fig.12 and turn the operator drive gear in the

direction of the arrow to the piston limit. Rotate though

approx. 5° in the opposite direction.

Closethegarage door andfitdrive shafts (T- fig.4) overthe

operator drive gearsand cuttosize asshown in figs. 6/7.Fit

bushings(C)andbrackets(L)onthedriveshaftsandsecure

brackets (L) on the door reinforcement ribbing taking care

to maintain correct alignment of the drive shafts.

Straight telescopic arm:

refer to fig.8 -

Curved telescopic

arm:

refer to fig.9

Open the garage door and position the telescopic arm as

indicated in figs. 8 or 9. Cut the outer profile at point A. Cut

the inner profile of the telescopic arm at reference point B.

N.B.Leaveagapofabout1cmattheendsofbothprofiles.

Insertthedriveshafts(T)intheinnerprofileofthetelescopic

arm (Q - fig.4), already cut to size, and drill an 8 mm hole.

Secure by means of an M8 bolt.

To ensure smooth door closing operation install a cushion

pad (T - fig.14). Alternatively, to prevent garage door off-

balanceandensureoptimaloperatorfunctioning,construct

and install an “L” bracket as shown in fig.15.

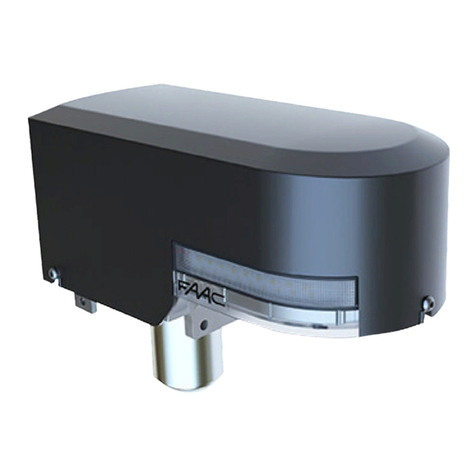

aelectronic control unit

bT 15 MP pushbutton

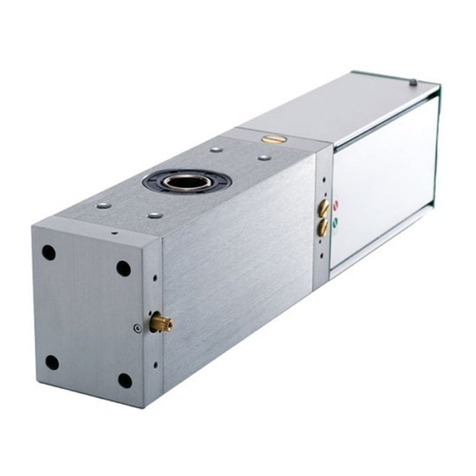

cFAAC 593 operator

dRx photocell

eplus radio receiver

fT 10 key-operated pushbutton

gTx photocell

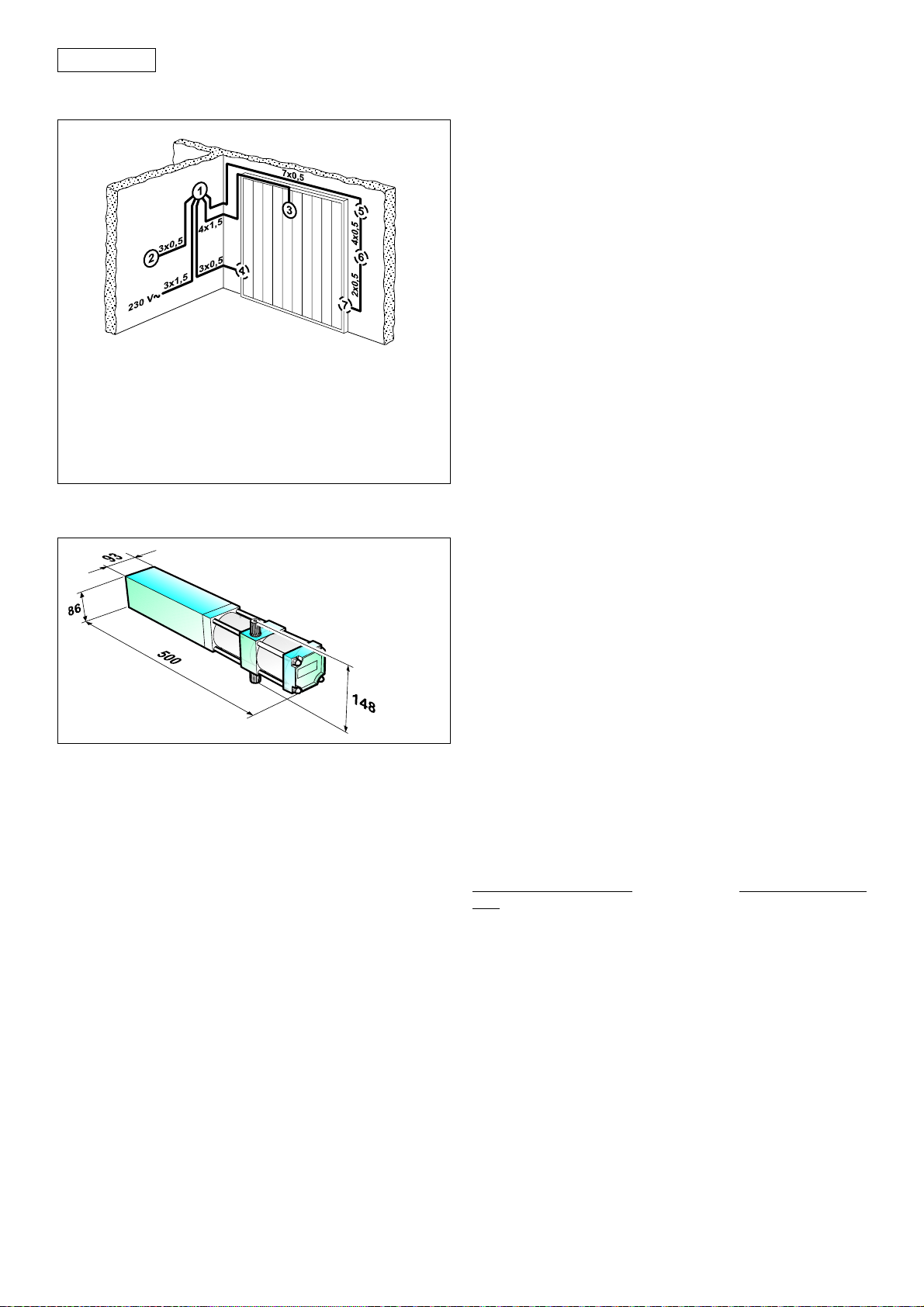

3. DIMENSIONS

Fig. 18

Fig. 17

4. INSTALLATION

4.1. PRELIMINARY CHECKS

Make sure that the dimensions of the door are within the

limits stated in the technical specifications. Make sure that

the door operates smoothly and has no stiff points. If

necessary, clean the tracks and lubricate them with a

silicon based lubricant. Do not use grease. Check the

condition of all door bearings and joints. Remove the

manual door locks so that when the door is closed it will be

locked only by the automation system. Make sure that

there is a 230 Vac power supply point in the garage, and

thatitis protected byan adequate residualcurrentcircuit-

breaker.

The FAAC 593 automation system is designed to operate

various types of garage doors with counterweights. Figs. 1,

2, and 3show the most common types: canopy door,

articulated panel, horizontal tracks. Either metal blocks or

bricks can be used as counterweights, though some door

manufacturersusespringsinsteadofweights.Checkinany

case that the door pivots correctly when opening and

closing.

4.2. INSTALLATION OF OPERATOR

Accessories of the FAAC 593 are supplied in two versions:

• “Welded assembly”: welded telescopic arms, drive

shafts, and mounting brackets.