Translation of the original instructions

1 Identification EX

Identification

II 2G Ex h IIC T4 Gb

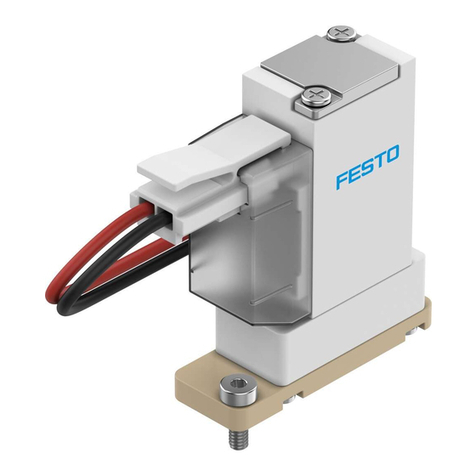

II 2D Ex h IIIC T105°C Db

–5°C£Ta£+40°C

Tab. 1

2 Further applicable documents

NOTICE!

Technical data for the product can have different values in other documents. For

operation in an explosive atmosphere, the technical data in this document always

have priority.

All available documents for the product èwww.festo.com/pk.

3 Safety

3.1 Intended use

The solenoid valve is intended for controlling pneumatic actuators.

3.2 General safety instructions

– The device can be used under the stated operating conditions in zones 1 and

2, explosive gas atmospheres, and in zones 21 and 22, explosive dust atmo

spheres.

– Carry out all work outside potentially explosive areas.

– Observe the operating instructions for the solenoid coil.

– Installation and commissioning should only be conducted by qualified per

sonnel.

– Only use media in accordance with the specifications.

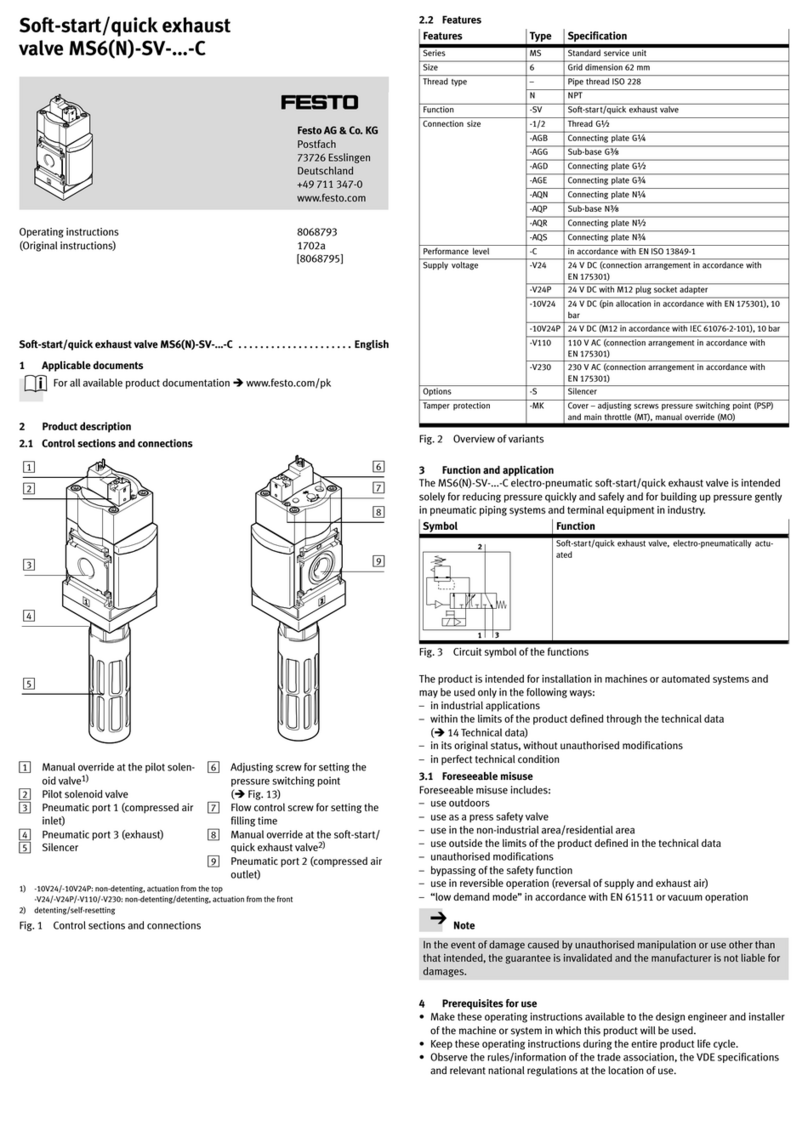

4 Function

By means of external electric switching, the valve pressurises the downstream

compressed air flows alternately or simultaneously. The bistable valve is

rerouted through reciprocal switching on of the voltage to the solenoid coils and

maintains the switching position up to the countersignal even after the signal is

removed.

5 Application

The explosion protection category of the entire system is dependent on the cat

egory of the combination of the solenoid valve and the solenoid coil.

6 Commissioning

WARNING!

The discharge of electrostatically charged parts can lead to ignitable sparks.

• Prevent electrostatic discharge through the use of appropriate installation

and cleaning measures.

• Include the device in the system’s potential equalisation.

NOTICE!

Related type of ignition protection: c (constructional safety)

NOTICE!

Strong chargegenerating processes can charge nonconductive layers and coat

ings on metal surfaces.

NOTICE!

Particulate matter in the compressed air can cause electrostatic charges.

NOTICE!

Escaping exhaust air can swirl up dust and create an explosive dust atmosphere.

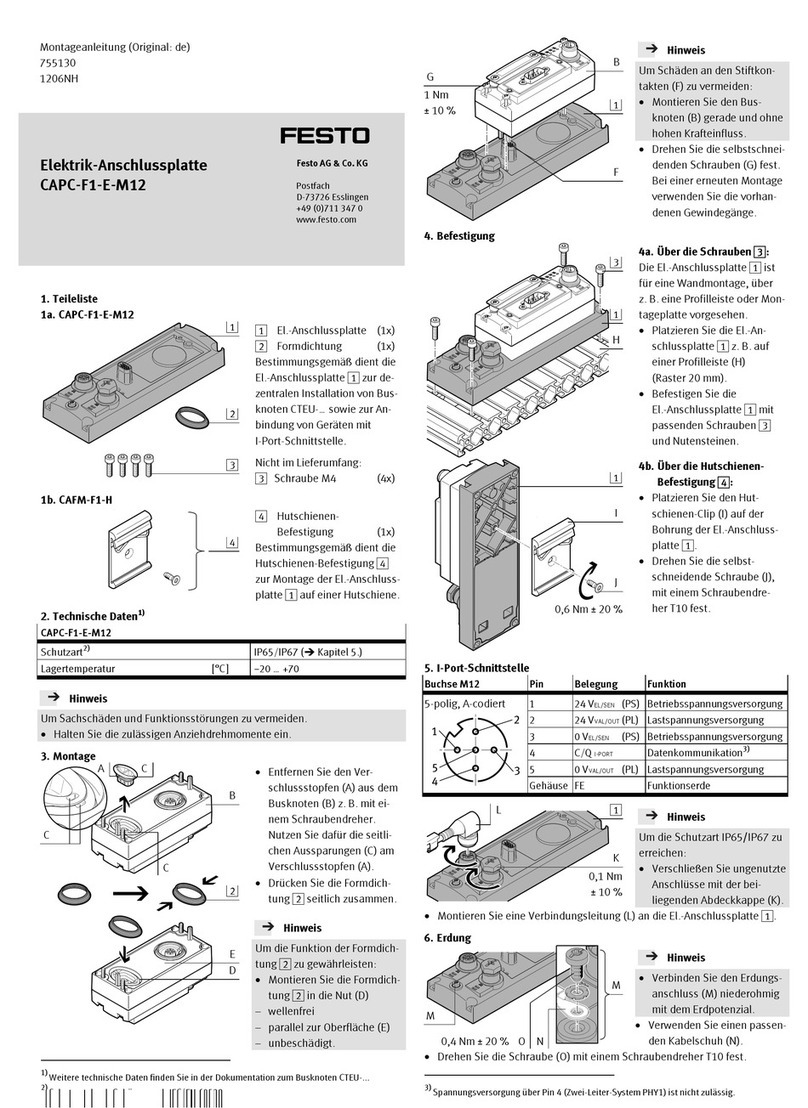

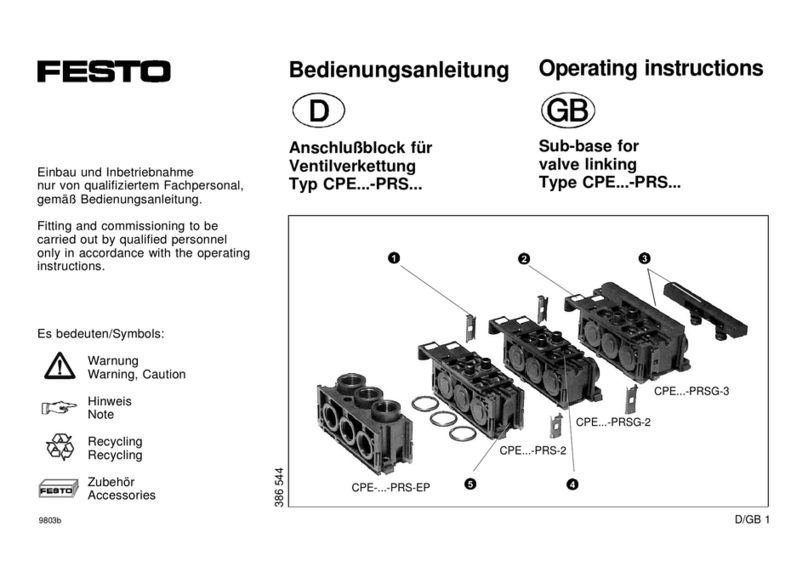

– For battery/block mounting, mount the valves to the manifold rails or mani

fold blocks intended for it.

The solenoid coil is mounted on the electrically actuated valves using the sup

plied spring washer and knurled nut.

– Push the solenoid coil and spring washer over the armature guide tube, tight

en the knurled nut. Tightening torque: 1…1.5Nm

WARNING!

Impact movements involving rust and light metals and their alloys can result in

the formation of sparks.

• No not use any tools with corroded surfaces.

• Protect the product from falling objects.

– Limit the number and dimensions of disassembled connections to a minimum

and use short tubing.

– Ensure that no mechanical stresses can occur.

– Seal unused openings with blanking plugs or slot covers.

– Ensure that surfaces to be cleaned can be easily accessed.

7 Operation

– Draw in operating medium outside potentially explosive areas.

– Do not operate the device with separate pilot air. Do not turn coding.

– Do not use LR intermediate pressure regulator plates in potentially explosive

areas. The vented air can stir up dust.

8 Malfunctions

Malfunction Remedy

Audible leakage at the connections Check fittings of the connections.

Incomplete ventilation of an output Ensure constant pressure in the system.

Switching failures

Considerably slower switching times

Check switching function of the valve for fluctu

ations in current, signal errors or delays.

Protect against penetration of foreign matter.

Replace device.

Tab. 2

9 Service and care

– Only clean the device with a damp cloth.

– Service device after 5 million cycles or not later than after 6 months.

The replacement of wearing and spare parts is possible in individual cases.

Repairs of this type must only be carried out by trained and authorised special

ists.

– Please contact your Festo technical consultant.

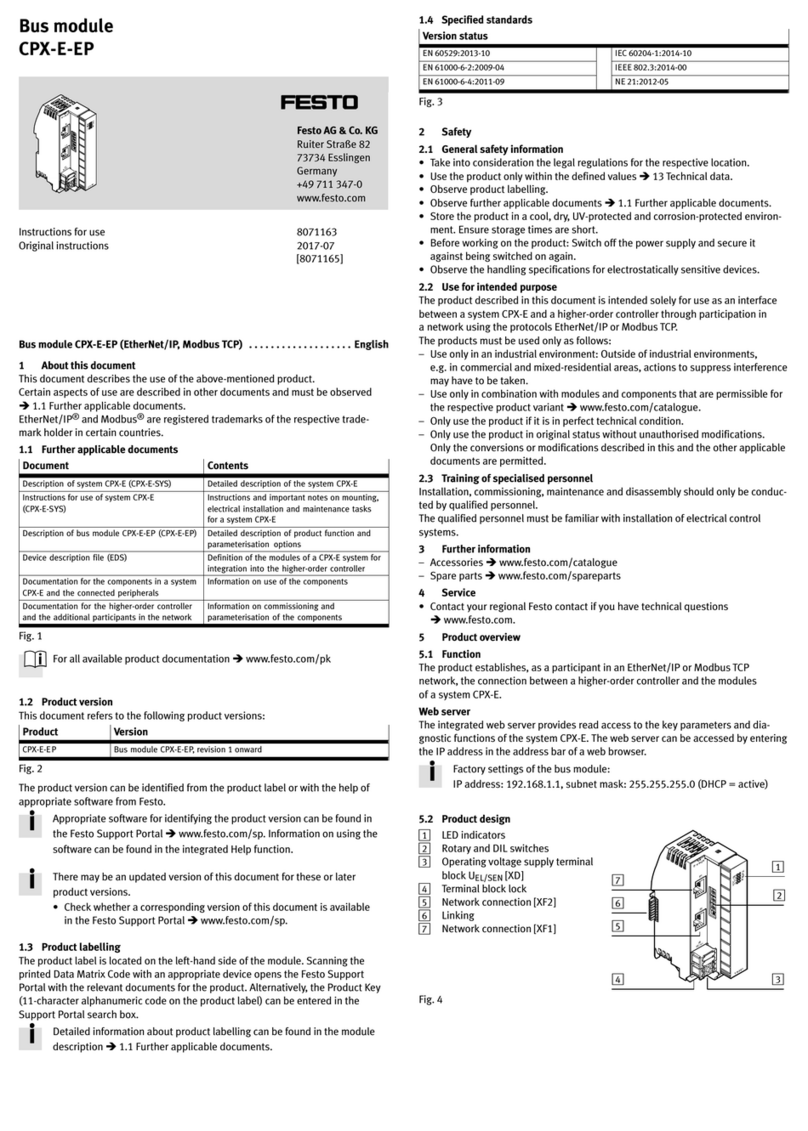

10 Technical data

Operating conditions

Operating medium Compressed air to ISO 85731:2010:[5::]

Max. operating pressure [bar] 10

Max. pilot pressure [bar] 10

Mounting position Any

Temperature ranges

Ambient temperature

(with solenoid coil)

[°C] -5…40

Temperature of medium [°C] -5…40

Tightening torque

Fitting [Nm] 1.5…2

Valve fastening [Nm] 3.5…4

8086852

(J)MFH...D...C-EX

Solenoid valve ISO

8086852

201805b

[8086854]

Operating conditions|EX

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com