Solenoid coil

VACC-S18-…-K4-…-EX4ME

II 2G Ex emb II T6, T5, T4

II 2D Ex tD A21 IP65 T80 °C, T95 °C, T130 °C

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions

(Original instructions)

8073493

2017-10d

[8073495]

Solenoid coil VACC-S18-…-K4-…-EX4ME English...........................

1 Further applicable documents

– Certification documents

– VOFC/VOFD assembly instructions

For all available product documentation èwww.festo.com/pk

2 Certified solenoid coils

Voltage Type Part no.

24 V DC/AC VACC-S18-35-K4-1U-EX4ME 562897

110 V DC/AC VACC-S18-35-K4-2U-EX4ME 562898

230 V DC/AC VACC-S18-35-K4-3U-EX4ME 562899

24 V DC/AC VACC-S18-120-K4-1U-EX4M E 3536527

110 V DC/AC VACC-S18-120-K4-2U-EX4M E 3536565

230 V DC/AC VACC-S18-120-K4-3U-EX4M E 3535568

60 DC VACC-S18-120-K4-27-EX4ME 3536569

48 DC VACC-S18-120-K4-7-EX4M E 3536573

24 V DC/AC VACC-S18-35-K4-1UF-EX4ME 570785

24 V DC/AC VACC-S18-120-K4-1UF-EX4M E 3535840

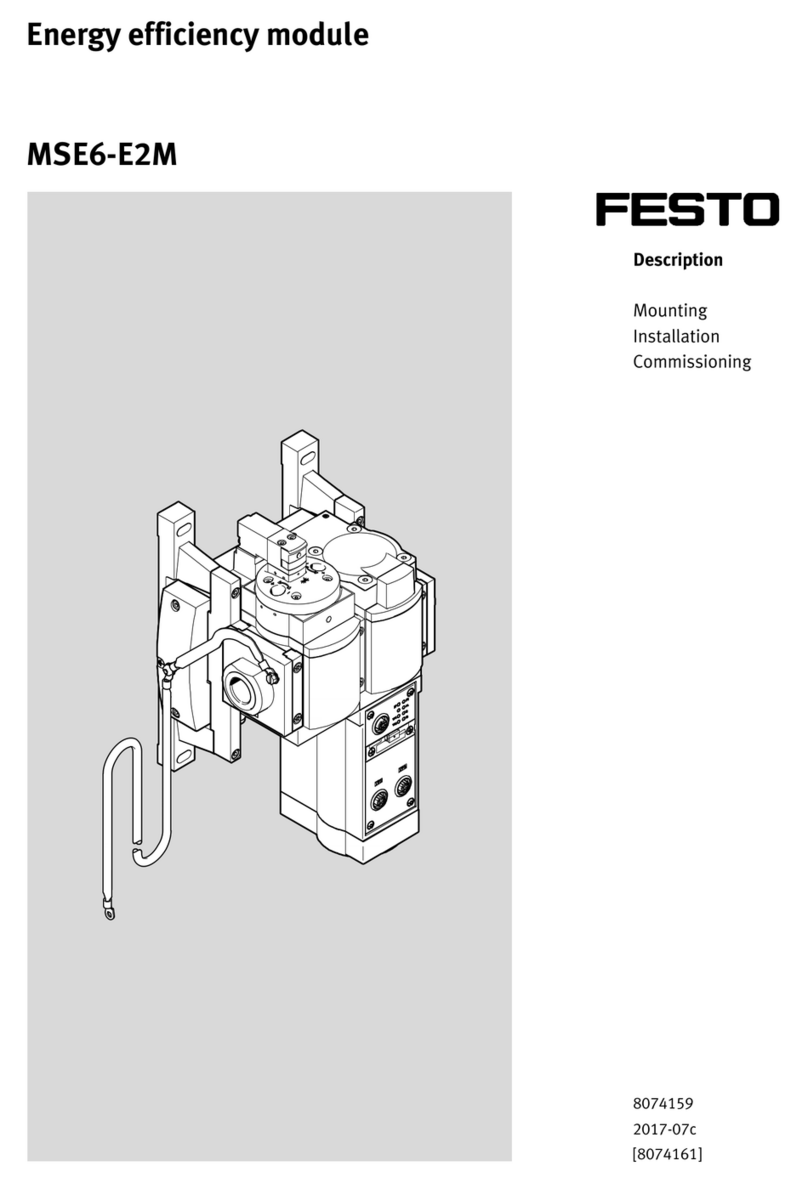

Fig. 1

3 Function

When switching on the voltage, the solenoid is energised and the valve is actuated.

A built-in bridge rectifier or a built-in varistor limits the switch-off overvoltage.

4 Application

The solenoid coil is intended to be used as an actuator for solenoid valves.

The solenoid coils can be used in combination with the specified solenoid valves

from Festo in zones 1 and 2 for potentially explosive gas atmospheres and in

zones 21 and 22 for potentially explosive dust atmospheres.

The suitability of other solenoid valves can only be determined in connection

with the assessment of further components of the subsystem. These must

achieve the same safety level.

Note

Label X: special conditions

Operate the solenoid coils (except variants -1UF-) only with upstream fuses.

èTechnical data and product label

Protect connecting cables that contain silicone or are not crack-resistant

against mechanical damage.

Protect the device from all mechanical damage.

For solenoid coils in direct current design -7- and -27-, the maximum permiss

ible ripple is 20 %.

Note

When using Festo solenoid valves:

Operate the solenoid valve only with compressed air or neutral gases.

The device is not intended to be used with other fluids.

Always draw in the operating medium outside the potentially explosive area.

Use only solenoid valves approved for potentially explosive areas.

5 Requirements for product use

Comply with all applicable national and international regulations.

Installation and commissioning should only be carried out by qualified electrical

specialists.

Use the device in its original status, without any unauthorised modifications.

The certification is no longer valid if the device is altered in any way by anyone

other than the manufacturer.

6 Commissioning

Observe the product labelling.

Operate solenoid coils only with upstream fuses (except variants -1UF-).

Do not commission the solenoid coil until after mounting.

Warning

The discharge of electrostatically charged parts can lead to ignitable sparks.

Prevent electrostatic discharge by taking appropriate installation and cleaning

measures.

Include the device in the system’s potential equalisation. The surface coating

of the Festo solenoid valves (VOFD-…) is electrically non-conductive.

Prevent charge-generating processes that are stronger than manual rubbing

of surfaces.

Do not mount the housing of the solenoid coils in an area of pneumatically

conveyed dusts (e.g. powder jet).

Note

Escaping exhaust air can swirl up dust and create an explosive dust atmosphere.