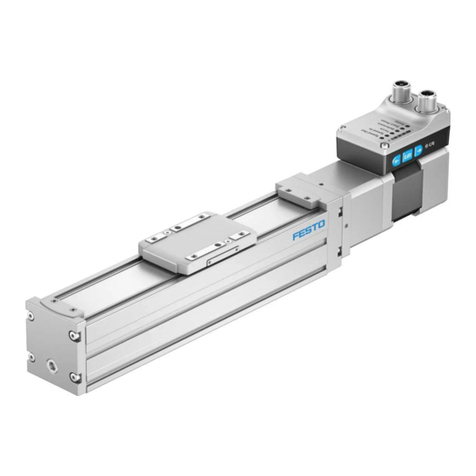

DFPI-...-ND2P-C1V-...-A

Linear drive

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Addendum document | Operating conditions EX

8168968

2021-11b

[8168970]

Translation of the original instructions

© 2022 all rights reserved to Festo SE & Co. KG

1Identification EX

Identification

II 3G

II 3D

Ex ec IIC T4 Gc X

Ex tc IIIC T120°C Dc X

Tab. 1: Identification

2Applicable documents

NOTICE

Technical data for the product can have different values in other documents. For

operation in an explosive atmosphere, the technical data in this document always

have priority.

All available documents for the product è www.festo.com/sp.

3 Certified products

Type Part number Type Part number

DFPI-100-...-ND2P-C1V-A 1548004 DFPI-100-...-ND2P-C1V-P-A 1548005

DFPI-125-...-ND2P-C1V-A 1548020 DFPI-125-...-ND2P-C1V-P-A 1548021

DFPI-160-...-ND2P-C1V-A 1548026 DFPI-160-...-ND2P-C1V-P-A 1548028

DFPI-200-...-ND2P-C1V-A 1548030 DFPI-200-...-ND2P-C1V-P-A 1548032

DFPI-250-...-ND2P-C1V-A 1548037 DFPI-250-...-ND2P-C1V-P-A 1548039

DFPI-320-...-ND2P-C1V-A 1548041 DFPI-320-...-ND2P-C1V-P-A 1548044

Tab. 2: Certified products

4Safety

4.1 Safety instructions

–The device can be used under the stated operating conditions in zone 2, explo-

sive gas atmospheres, and in zone 22, explosive dust atmospheres.

–Operate the device with compressed air that as a minimum conforms to the

quality class in accordance with ISO 8573-1:2010: [7:4:4]. Information on the

operating medium: oiled operation not permitted.

–The device is not intended for use with other fluids.

–Extraction of the operating medium outside the potentially explosive area.

–The device may only be used in the delivered configuration in a potentially

explosive atmosphere.

–Use the device in its original status, without any unauthorised modifications.

–Installation, commissioning, maintenance and disassembly should only be con-

ducted by qualified personnel.

–All work must be carried out outside of potentially explosive areas.

–Avoid lateral forces and torques on the piston rod.

4.2 Intended use

The linear drive is intended for the transported of masses and the transmission of

forces.

4.3 Identification X: special conditions

–Danger of electrostatic discharge.

–The device must be operated only in an environment with a minimum of con-

tamination level 2, as defined in IEC 60664-1.

–Ambient temperature -5 °C £ Ta £ +50 °C.

5 Function

Pressurising the cylinder chambers causes the piston in the pipe to move back

and forth. The piston rod transfers the movement outwards.

The integrated positioner performs position control of the piston rod within the

available stroke range.

The integrated displacement encoder transmits the current piston position to the

higher-order system as an analogue voltage signal.

6 Commissioning

WARNING

The discharge of electrostatically charged parts can lead to ignitable sparks.

• Prevent electrostatic charging by taking appropriate installation and cleaning

measures.

• Include the device in the system equipotential bonding.

• The piston rod is electrically insulated from the actuator. Include the piston rod

separately in the system equipotential bonding.

WARNING

Combustible sparks can occur with coated metal parts.

• Prevent processes that are strongly charge-generating.

WARNING

Unsuitable accessories affect the type of protection.

• Only use cable connectors approved for Ex-e type of protection with a corre-

sponding IP degree of protection or the NHSB connecting cable.

NOTICE

Escaping exhaust air can swirl up dust and create an explosive dust atmosphere.

–Connect the device outside the potentially explosive area with the connecting

cable or in a type of protection suitable for zones 2 and 22.

7Maintenance and care

–Check the operational reliability of the device regularly. Interval: 2 million

movement cycles or after 6 months at the latest.

–When using the device in a dusty environment: check the guide rods and

bearings at shorter intervals to ensure that they are functional according to the

ambient conditions.

–Wear and spare parts can be replaced in individual cases. Work of this type

must be carried out by trained and authorised specialists only.

Malfunction Remedy

External damage after visual inspection Replace device.

Audible leakage at the rod seal Replace device.

Cylinder not securely mounted, mounting on

piston rod not secure

Tighten the retaining screws.

Dry lubricant residue stuck firmly to the

piston rod

Clean the piston rod with a soft cloth.

Longitudinal ridges on the piston rod Replace device.

Non-uniform running behaviour Replace device.

Deterioration of the guide qualities due to

increased bearing play

Replace device.

Increased noise generation Replace device.

Tab. 3: Fault clearance

8 Technical data

DFPI-...-ND2P-C1V-...-A

Operating pressure [MPa] 0.3 … 0.8

Ambient temperature [°C] -5 … +50

Temperature of medium [°C] -5 … +50

Relative humidity [%] 5 … 100

Operating medium Compressed air according to ISO 8573-1:2010:[7:4:4].

Lubricated operation not permissible.

Operating voltage range [V DC] 22.8 … 26.4

Nominal operating voltage [V DC] 24

Signal connections

Initialisation [V DC]

[mA]

22.8 … 26.4

2.5

Setpoint input [mA] 4 … 20

Actual value output [mA] 4 … 20

Degree of protection IP65, IP67, IP68, IP69K NEMA 4

Materials

Piston rod High-alloy stainless steel

End cap Anodised wrought aluminium alloy or

Anodised and painted wrought aluminium alloy or

Painted cast aluminium

Bottom cover (bearing cap)

Cylinder barrel

DFPI-100/-125/-160/-200 Anodised wrought aluminium alloy

DFPI-250/-320 High-alloy stainless steel

Screws