Sub-D plug connector1), 9-pin Pin2) Allocation Function

1 C/Q Data communication

20 VVAL/OUT (PL) Load voltage supply

30 VEL/SEN (PS) Operating voltage supply

424 VVAL/OUT (PL) Load voltage supply

524 VEL/SEN (PS) Operating voltage supply

1) On the valve terminal

2) Pin 6 … 9 not allocated

Fig. 3

6 Addressing

Note

– Addresses may be shifted if the valve terminal is extended.

– If a monostable 5/2-way valve (requiring an address) is mounted on a valve

position that supports the actuation of 2 addresses, one address remains

unused.

6.1 Addressing rules:

– Address assignment is in ascending order without gaps, from left to right.

– Address assignment is independent of whether the manifold sub-base is

equipped with a valve or a cover plate.

– Depending on the integrated electronics module, a valve position, comprising a

manifold sub-base with electronics module, occupies the following number of

addresses:

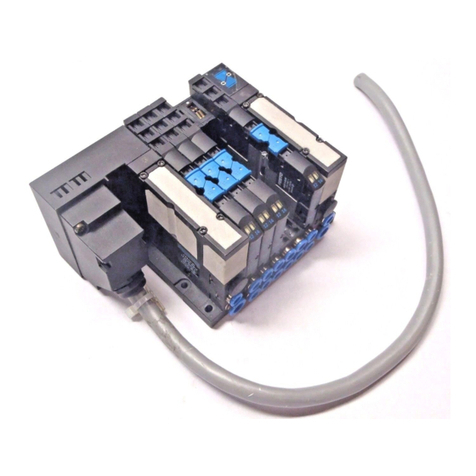

Colour of the electronics module Number of occupied addresses/valve position

Grey 1

Black 2 – Less significant address for coils 14

– Higher-value address for coils 12

Fig. 4

– A supply plate does not occupy an address (blue electronics module).

6.2 Addressing example

The following example shows the address allocation of the valve terminal with

8 valve positions (top view).

1

2

0

35

4

7

68

10

11

9

12

4

3

1

2

5

66 7

1Less significant addresses of coils 14

2Higher-value addresses of coils 12

3Supply plate with blue electronics

module

4Manifold sub-bases with grey elec

tronics module and valve

5Manifold sub-base with black elec

tronics module, without valve

6Manifold sub-bases with black

electronics modules and valves

7Manifold sub-base with black elec

tronics module, valve and addi

tional supply

Fig. 5

7 Installation and commissioning

Installation and commissioning of the pneumatics as well as maintenance

and modification of the valve terminal can be found in the description

MPAC-VI-...

7.1 IO-Link mode

The valve terminal can also be operated as an IO-Link device. The IODD configura

tion file required for this can be downloaded at èwww.festo.com/sp.

7.2 Malfunction and error handling

Malfunctions and statuses are transmitted in the form of event codes to the master.

Event code Malfunction and error handling Type

MSB LSB

50h 00h Device errors

Switch device off and back on. If the error is still present,

the device is defective and needs to be replaced.

Error

51h 12h Error in the load voltage supply

Check the load voltage supply

Warning

Fig. 6

8 Technical data

Valve terminal with I-Port/IO-Link interface:

General technical data èDescription MPAC-VI-...

Ambient temperature [°C] -5 … +60

Storage temperature [°C] -20 … +40

Maximum number of valve posi

tions

32

Maximum number of controllable coils 32

Degree of protection1) IP65/IP67 in accordance with IEC/EN 60529

IP69k in accordance with DIN 40050 part 9

NEMA6 in accordance with NEMA 250

Protection against electric shock, protec

tion against direct and indirect contact in

accordance with IEC/EN 60204-1

By means of PELV power circuit

Power supply valve terminal4)

– Operating voltage (PS), polar

ity-safe nominal value (toler

ance range)

[V DC]

24 (18 … 30)

– Load voltage (PL) nominal

value (tolerance range)

[V DC]

24 (18 … 30)

Valve terminal intrinsic current consumption at 24 V DC

– Operating voltage supply

UEL/SEN (PS)

[mA] 30

– Load voltage supply

UVAL/OUT (PL)

[mA] 30

Current consumption (per coil, with LED) at 24 V DC

– Nominal pick-up current [mA] 50

– Pick-up duration [ms] 25

– Nominal current with current

reduction (holding current)

[mA] 10

Mains buffering time

(only operating voltage (PS))

[ms] 10

I-Port/IO-Link connecting cable

– Wire cross section, at least [mm²] 0.5

– Max. length, unshielded [m] 20

IO-Link characteristics

– Operating mode (data transfer rate) COM 3 (230.4 kBaud)

COM 2 (38.4 kBaud)

– Specification Revision 1.1 (backwards compatible)

– Data out 4 bytes (1 … 32 valves)

Electromagnetic compatibility (Emitted in

terference2), resistance to interference3))èDeclaration of conformity (www.festo.com)

Tightening torque

– Electrical connecting cable [Nm] 0.5 ± 10 %

1) Requirement: valve terminal completely mounted, plug connector inserted. Observe that connected

devices might only satisfy a lower degree of protection, a smaller temperature range, etc.

2) The valve terminal is intended for use in an industrial environment. Measures for interference suppres

sion may need to be implemented in residential areas.

3) Use connecting cables with a length of maximum 30 m.

4) The operating voltage supply is provided via the CTEU bus node or IO-Link master. The load voltage

supply is through the CTEU bus node or, for IO-Link, through a separate feed. Separate fuses are re

quired for operating and load voltage.

Fig. 7