GE;K-730~

Low

Voltage

Power

Circuit

Breakers

MANUAL

MAINTENANCE

- .

~

CLOSING

OF

ELECTRICAL

BREAKE~S

· An electrical

breaker

may be closed manually

by _means of the maintenance handle furnished

'with the

breaker.

·

·

To

observe

~e

operation of the

breaker

with- ·

out

power, with the

break~r

open and

springs

discharged, proceed

as

follows:

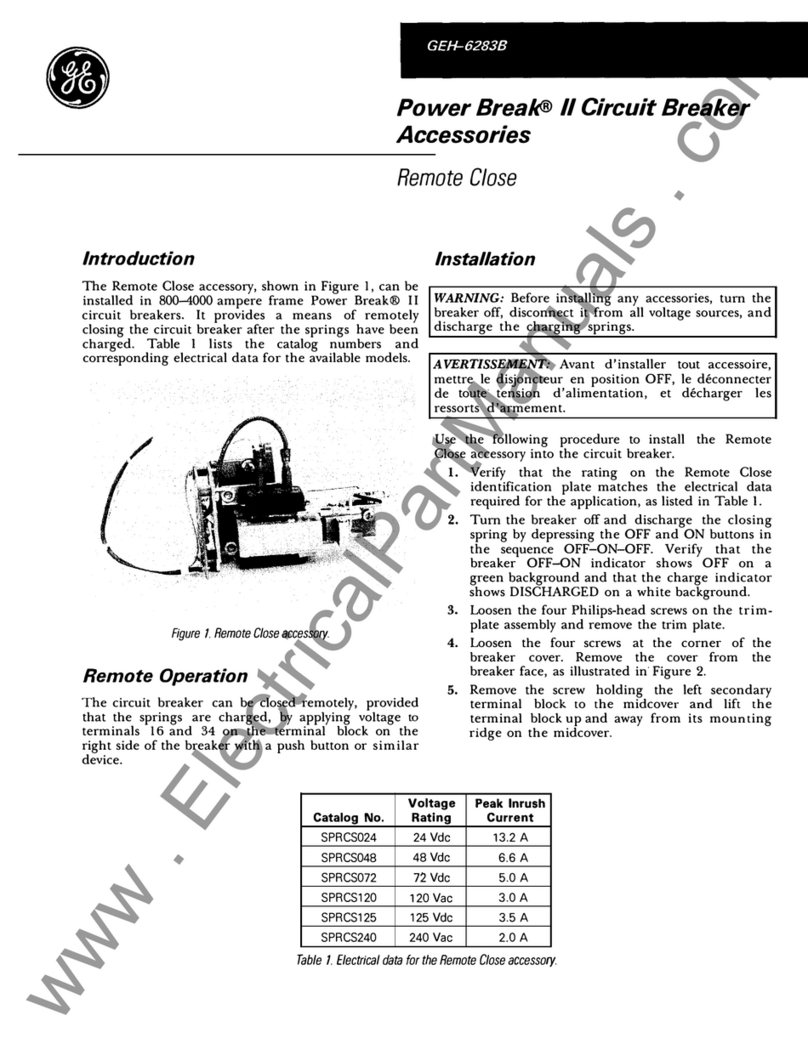

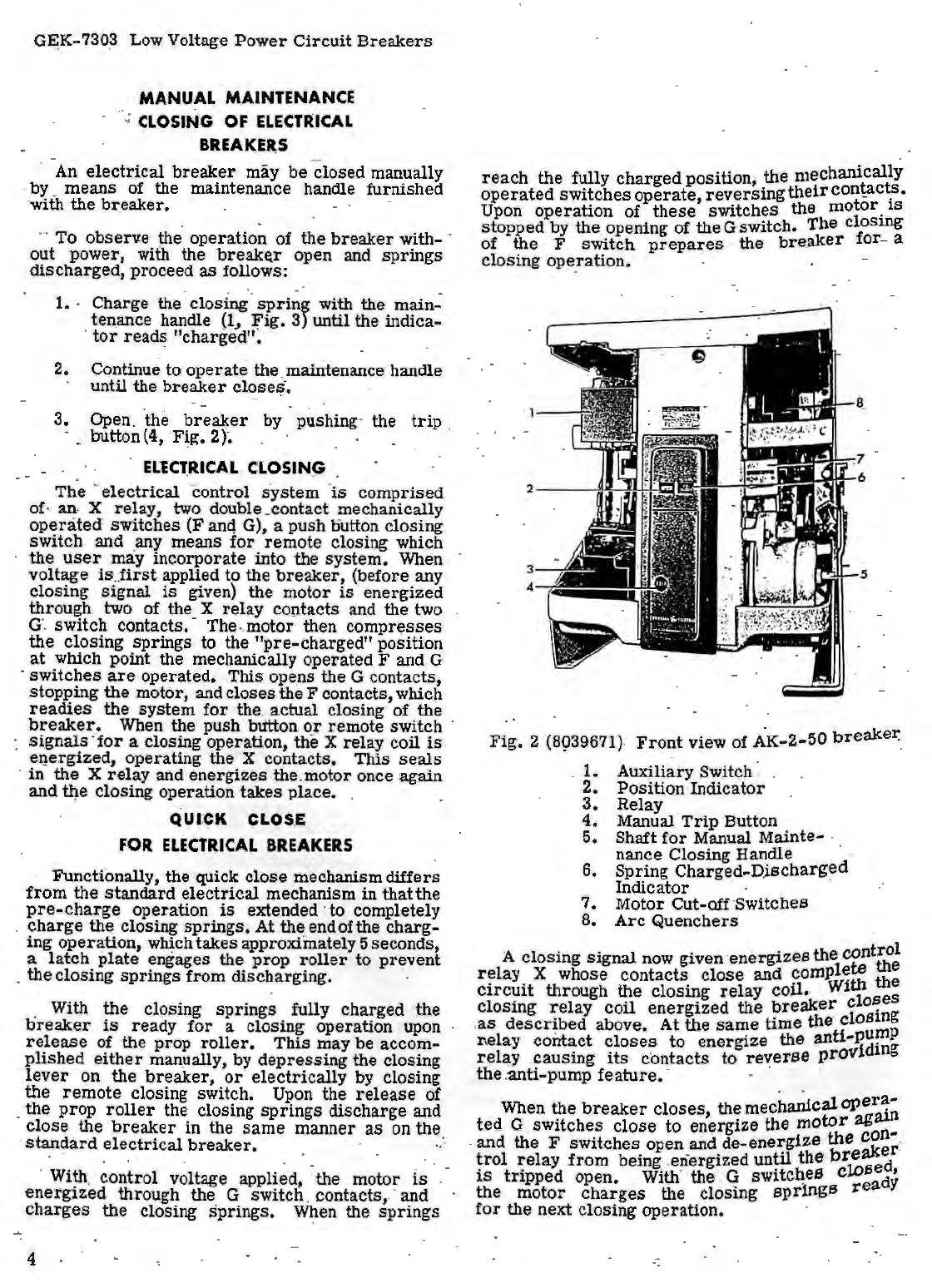

1. · Charge the·closing

spring

with tbe main~

te~ance

han~e

(1,

Fig.

3) until the indica-

tor

rea~

"charged": .

2. Continue to

operate

the.maintenance handle

until the

breaker

close~.

3.

Open. ·the

breaker

by . pushing· the

trip

.

· _·button(4, "

F~1t.

2)~

. . .

ELlCl'.RICAL

CLOSIN~

The

-

electrical

control s·ystem ·

is

comprised

of-an- X relay, two double_contact mechanically

operated

switches (F anq G), a push outton closing

switch

and _any means

for

remote closing which

the

user

may incorporate into the

system.

When

voltage

is

.

.first

.applied to the

breaker,

(before any

closing s'ignal

is

given) the motor

is

energized

through two of the X relay contacts and the two

a

·.

switch

contacts.· The-.motor then

compresses

the closing springs to the

"pre-charged"

position

at

which point the mechanically operated F and G

·

switc~es

are

ope_

rated.

This ope_

ns

the G contacts,

stop~mg the motor, and closestheF contacts,whicp

readies

the

system

for

the. actual closing of the

breaker

.. When the push button

~r

remote switch ·

signals

·

for

a closing operation, the X relay coil

is

e~ergized, operating the X contacts. This

seals

·

in

the

X

relay

and energizes the.motor once again

and

tl?,e

closing operation

takes

place. . .

QUt:CK CLOS.E

FOR ELECTRICAL BREAKERS

. Functionally, the ·quick close mechanismdiffers

from

the

standard

electrical

mecbanism

in

that

the

pre-charge

operation

is

extended ·to completely

charge

the closing

springs.

At

theendofthe

charg-

ing oper~tion,

w~ch

takesapproximately5seconds,

a

latch

plate

engages the prop

roller

to

prevent

_theclosing springs from discharging. .

. With

the

closing

springs

fully charged the

breaker

is

ready

for

a closing operation upon

release

of the prop

roller.

This

may be accom-

plished

either

m~ually,

by

depressi

.ng the closing

.

lever

on. the

breaker,

or

electrically

by closing

the

remote

closing switch. Upon the

release

of

. the prop

roller

the closing

springs

discharge and

close

the

breaker

in the

same

manner

as

on the

·

stan~ard

electrical

breaker.

·

Wi~

. control voltage appli~d, :the motor

is

·.·

energized

through the .G switch. contacts, ·and

charges

the closing springs. When the

springs

4

reach

the

fully charged position; the mechanically

operated

switches

operate,

reversing

their

coniact:S.

Upon

operation

of

these

switches the

motor.

1s

stopped by the.opening of theGswit~h. The closing

of the F

switch

prepares

the

bre

.

aker

for- a

closing

operation.

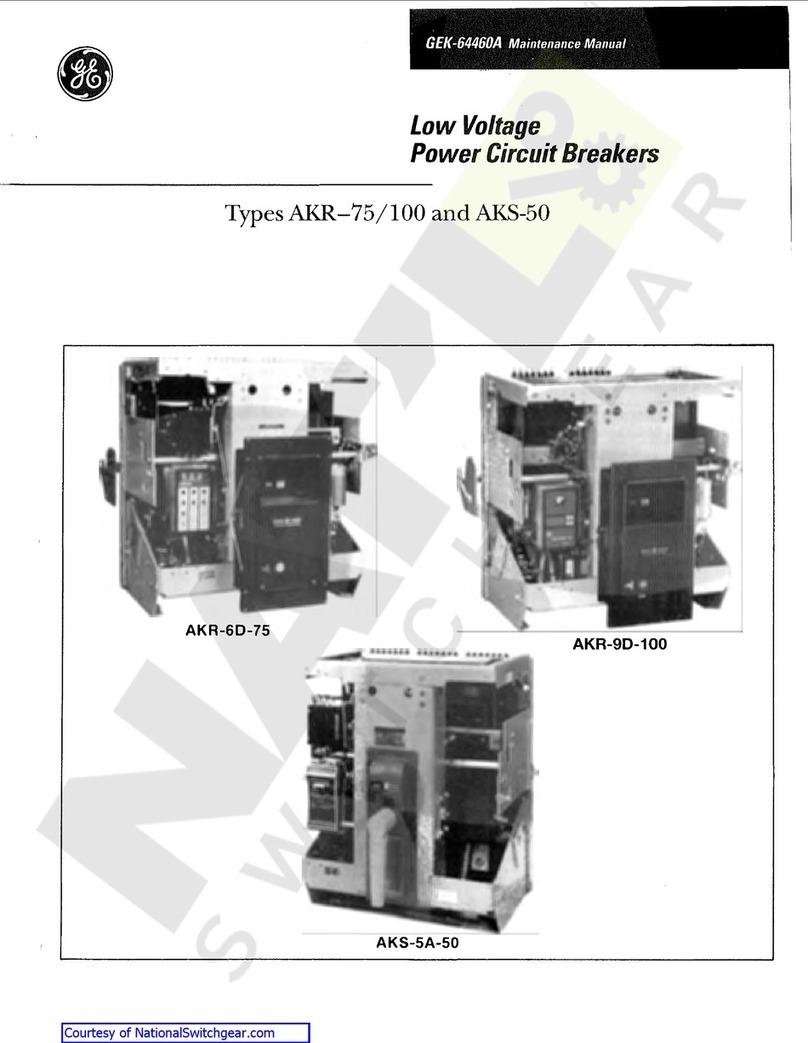

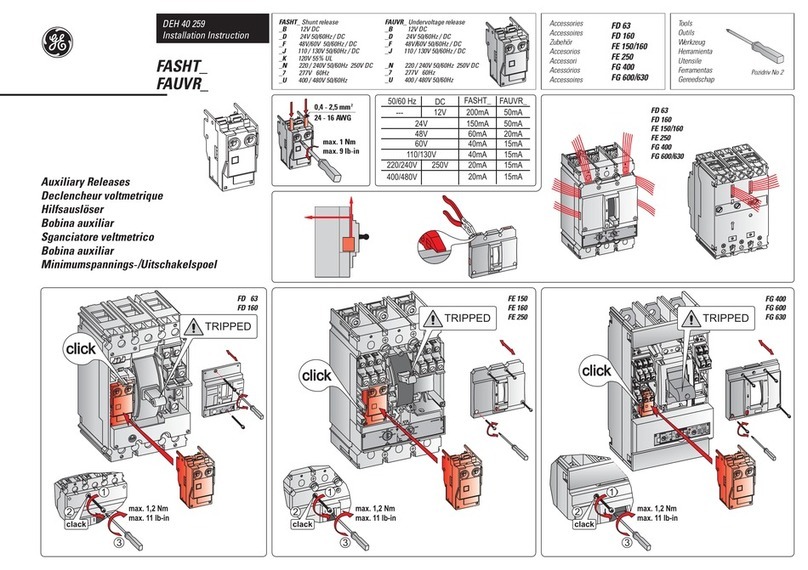

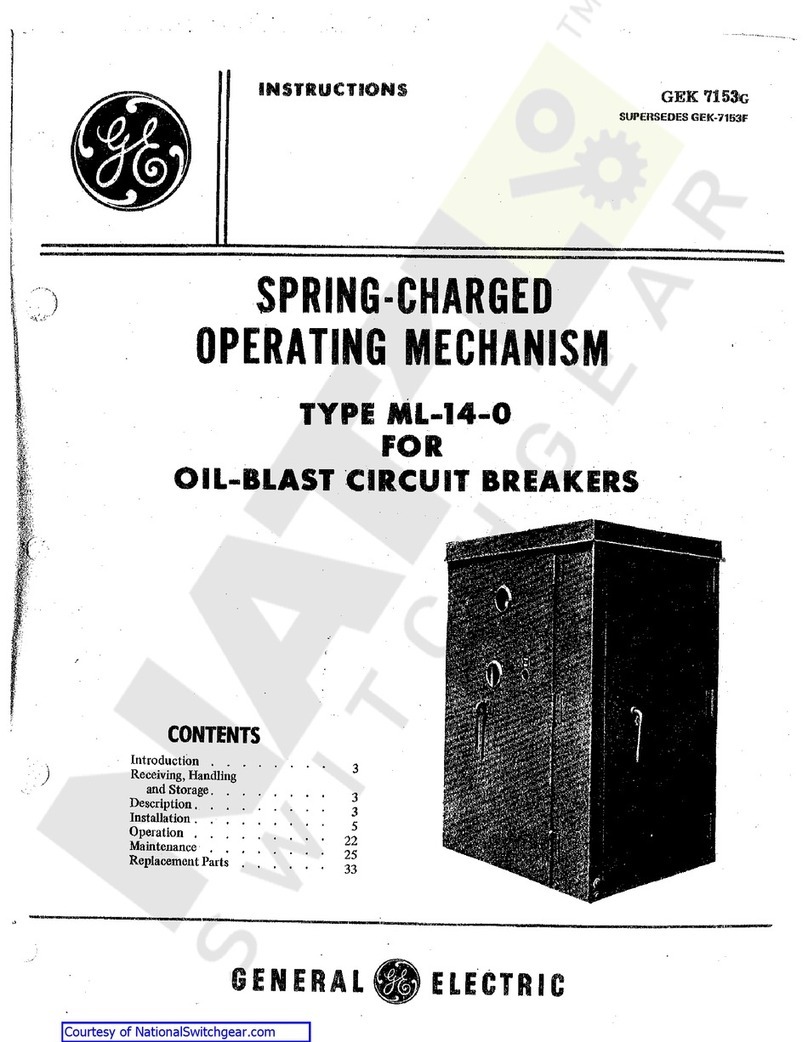

Fig.

2 (8939671)-

Front

view of AK-2-50

bre~e~

.

1.

Auxiliary Switch· .

2. Position Indicator

3.

Relay

4. Manual

Trip

Button

5. Shaft

for

Manual Mainte- ·

nance Closing Handle · ·

6.

Spring

Charged-Discharged

Indicator · ·

7. Motor Cut-off·Switches

8.

Arc

Quenchers

A closing

signal

now given·

energizes

the

cont;;

relay

X whose contacts

close

and

comple:

the

circuit

through the closing

relay

coil.

. Wi 8

closing

relay

coil energized the

breaker

clo~eg

.

as

descr~bed above. At the

same

time

the·

clos:P

l\elay contact

closes

to energize the anti-pU

rel~y .causing

its

c·

ontacts

to re\_'erse

providing

the.anti-pump

feature.

·

When the

breaker

closes,

themechanical

oper~~

ted

G switc

hes

close

to energize the

motor

ag~-

. and the F switches open and de-ene:1;gize

the

:er-

·

trol

relay

from

being .energized

until

the

brtsed

is

tripped

open. With' the .G switc~es c

dy'

the motor

charges

the closing

sprlngs

rea

for

the next closing operation.