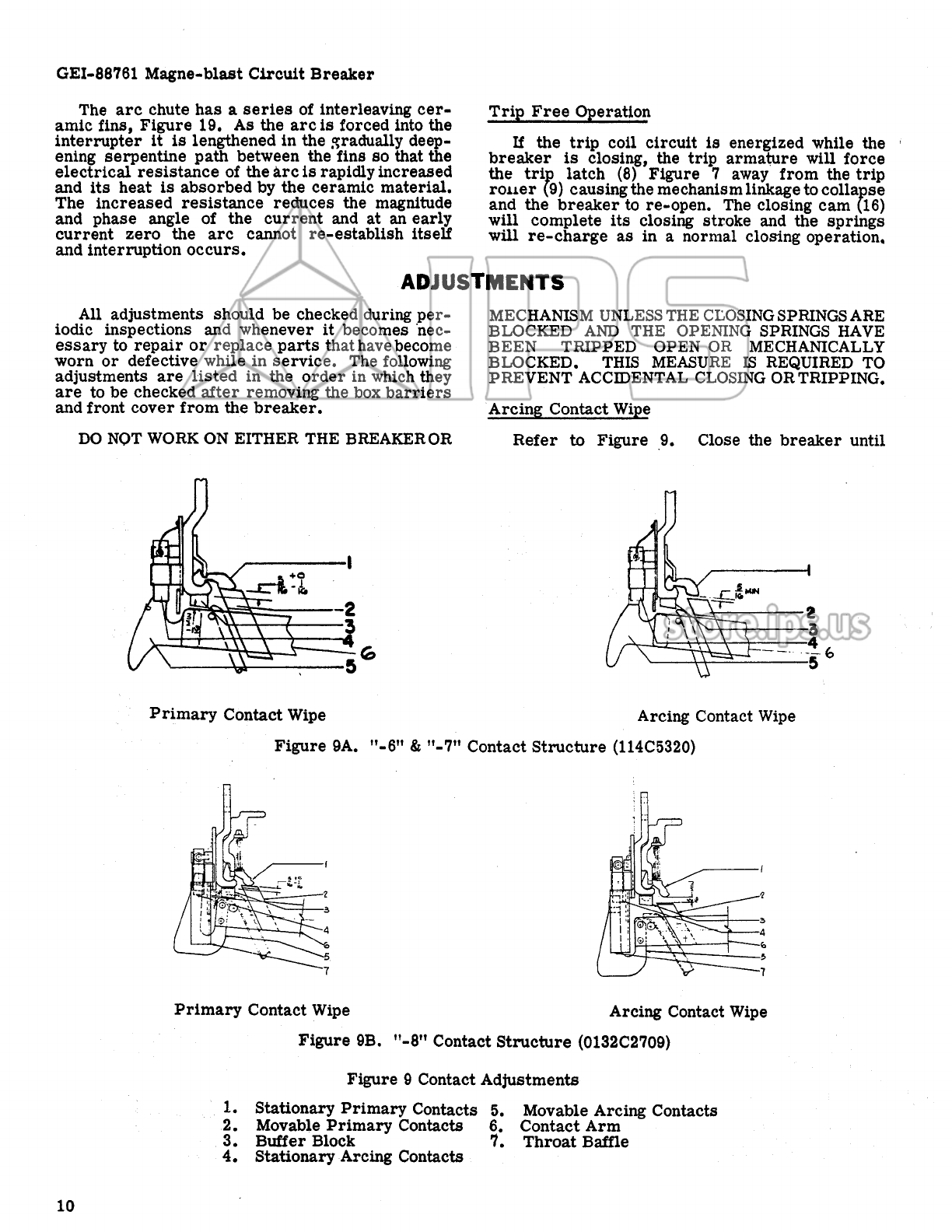

GE AM-4.16-250-6 User manual

Other GE Circuit Breaker manuals

GE

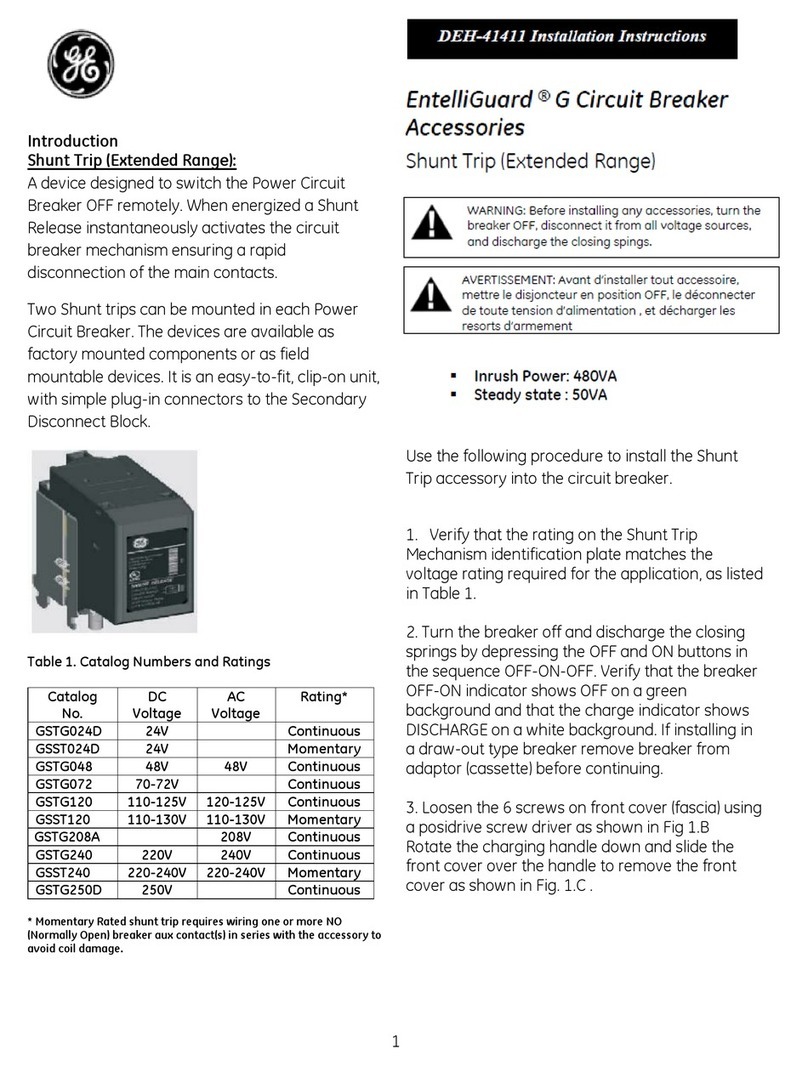

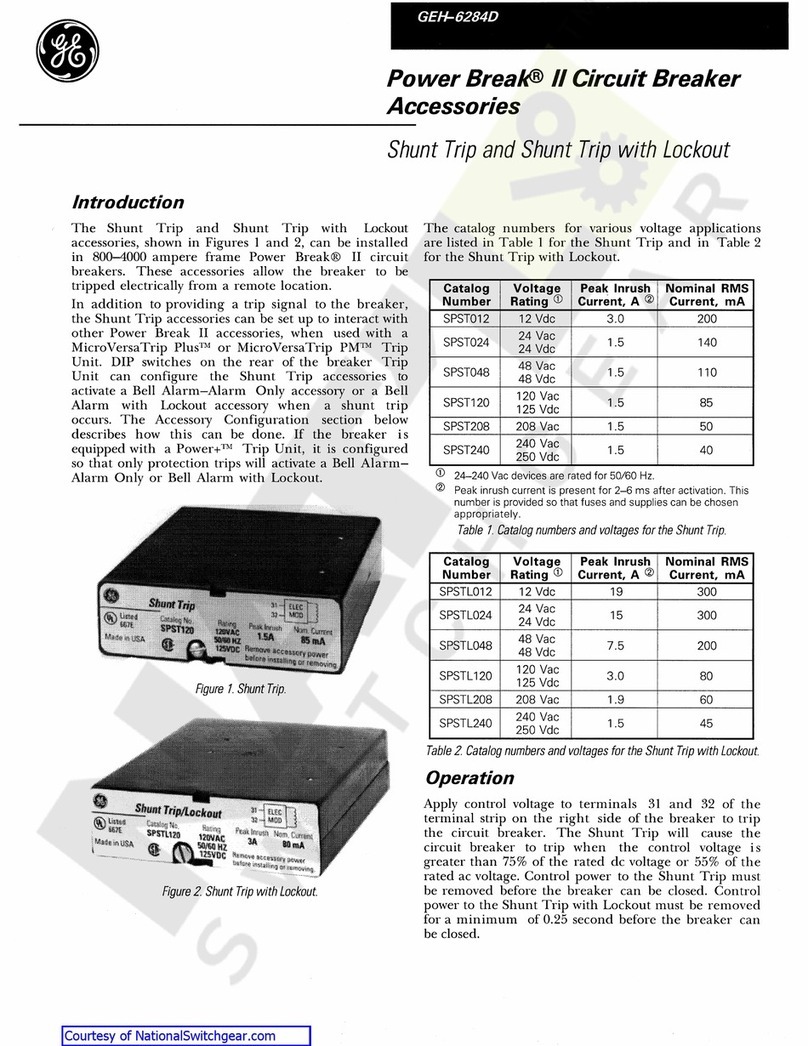

GE Shunt Trip User manual

GE

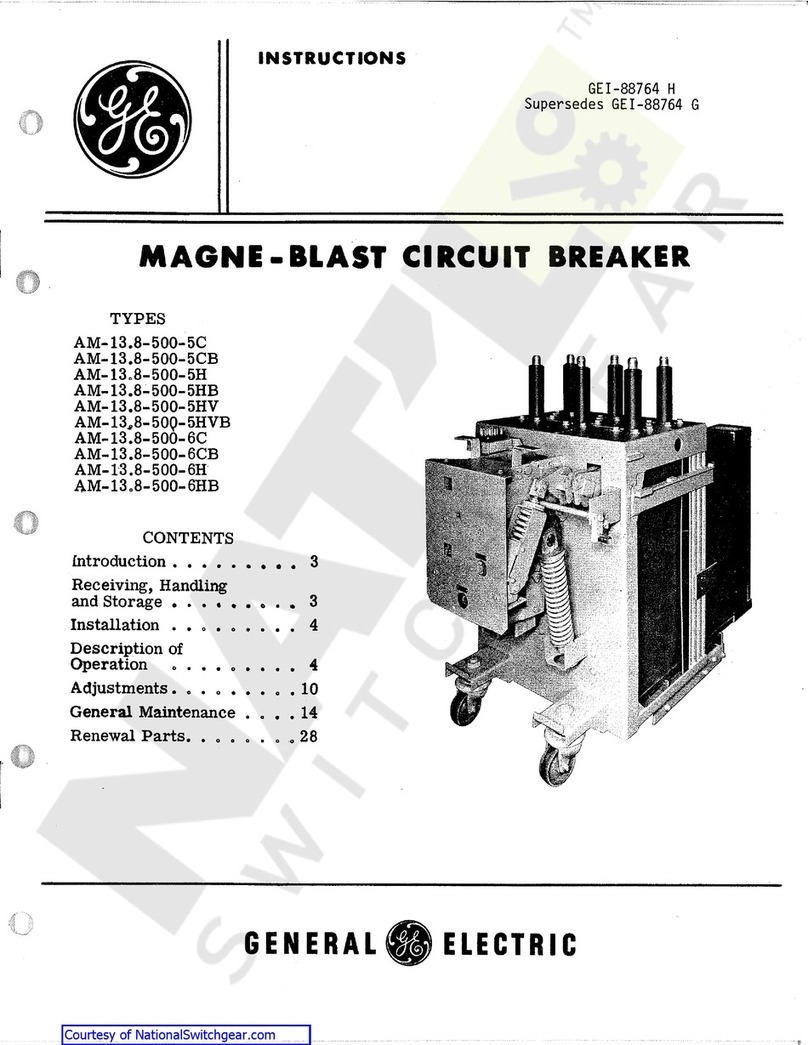

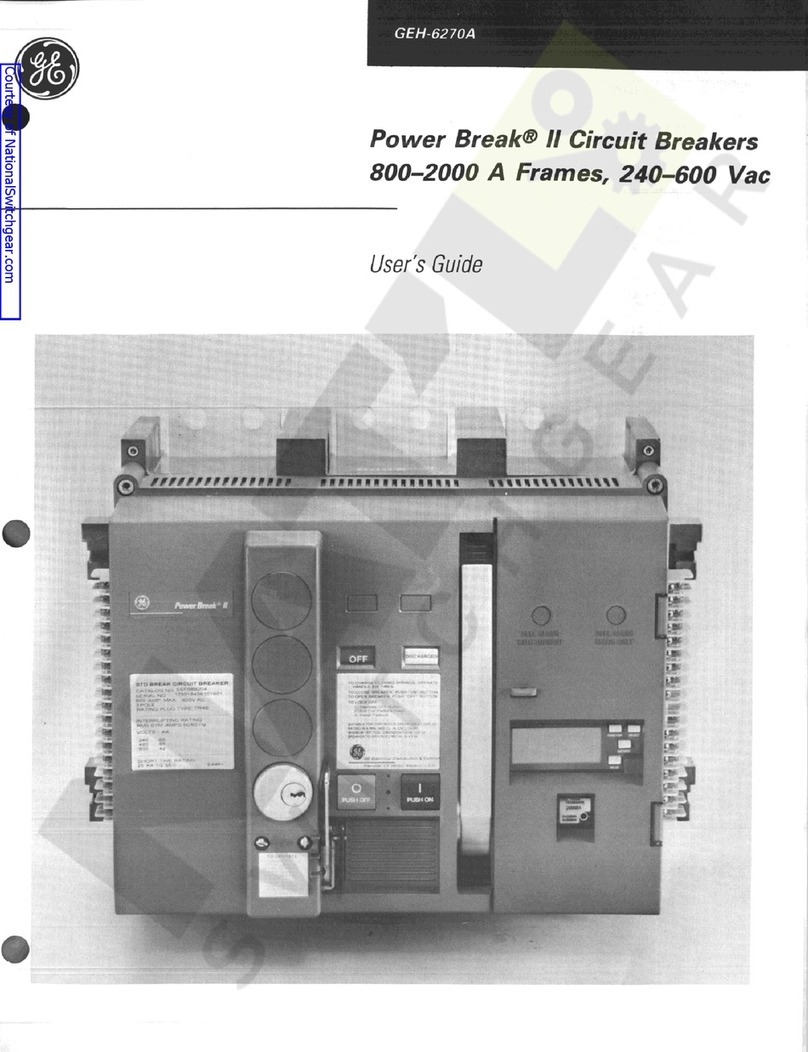

GE Power Break II User manual

GE

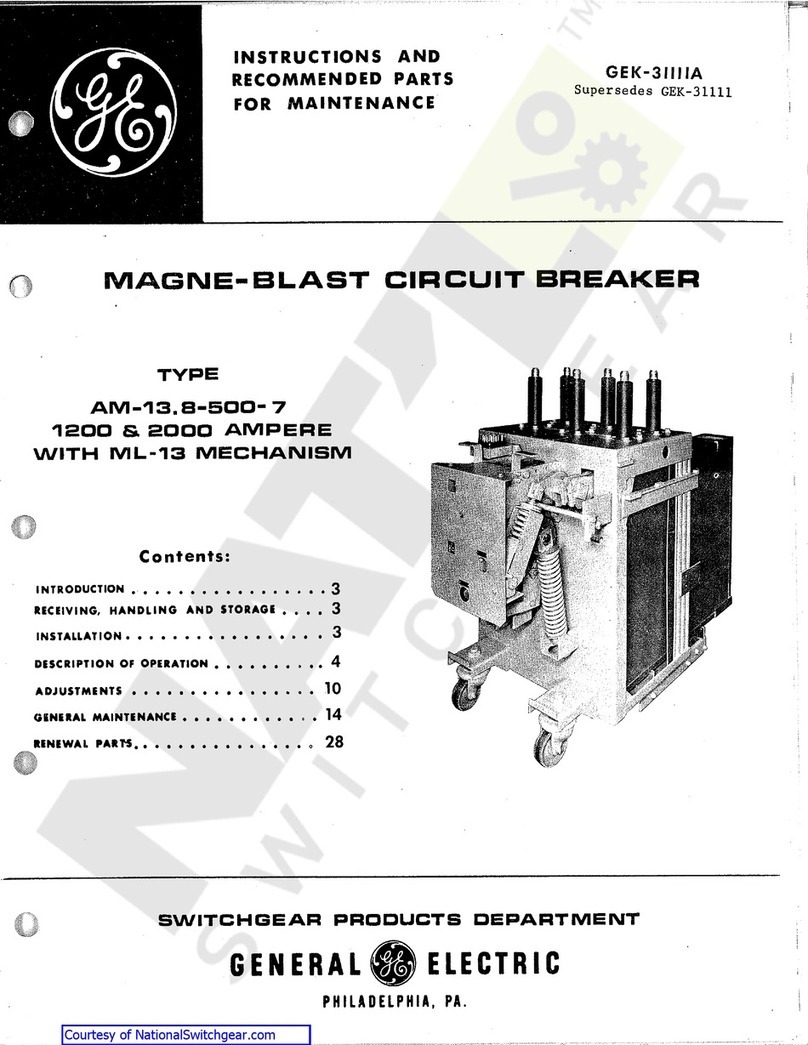

GE AM-13.8-500-7 User manual

GE

GE Rapid TripFix User manual

GE

GE AM-13.8-750-5 User manual

GE

GE AM-4.16-250-6C User manual

GE

GE AM-13.8-500-5A User manual

GE

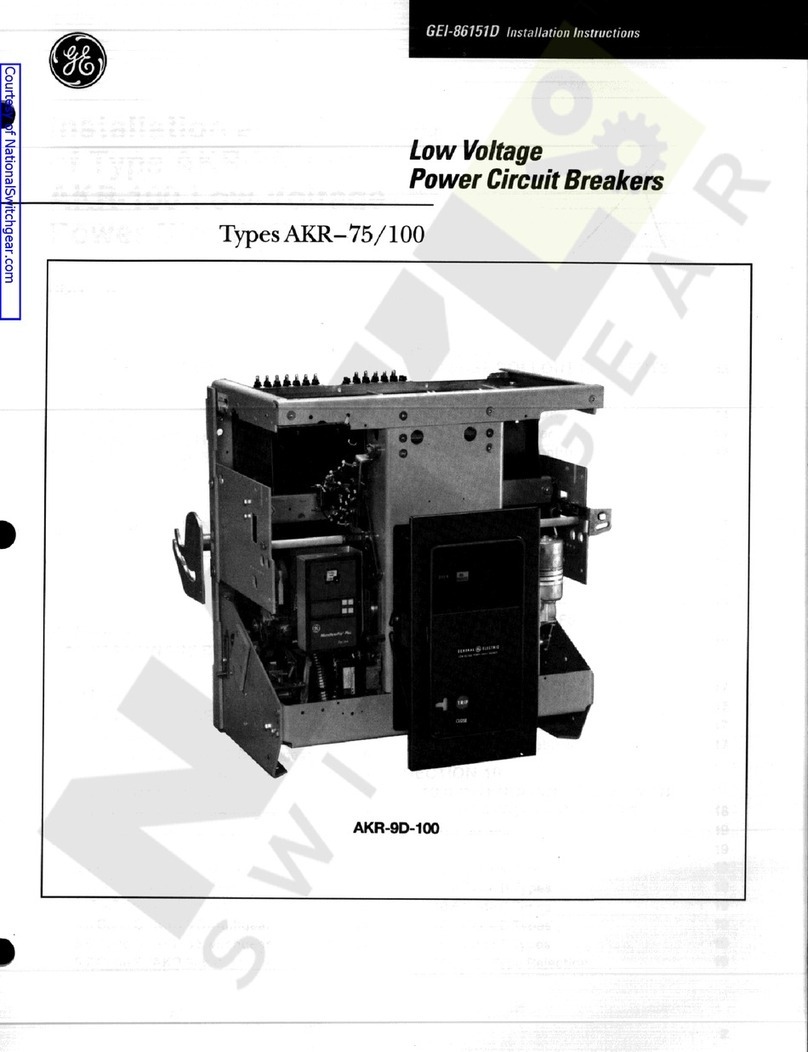

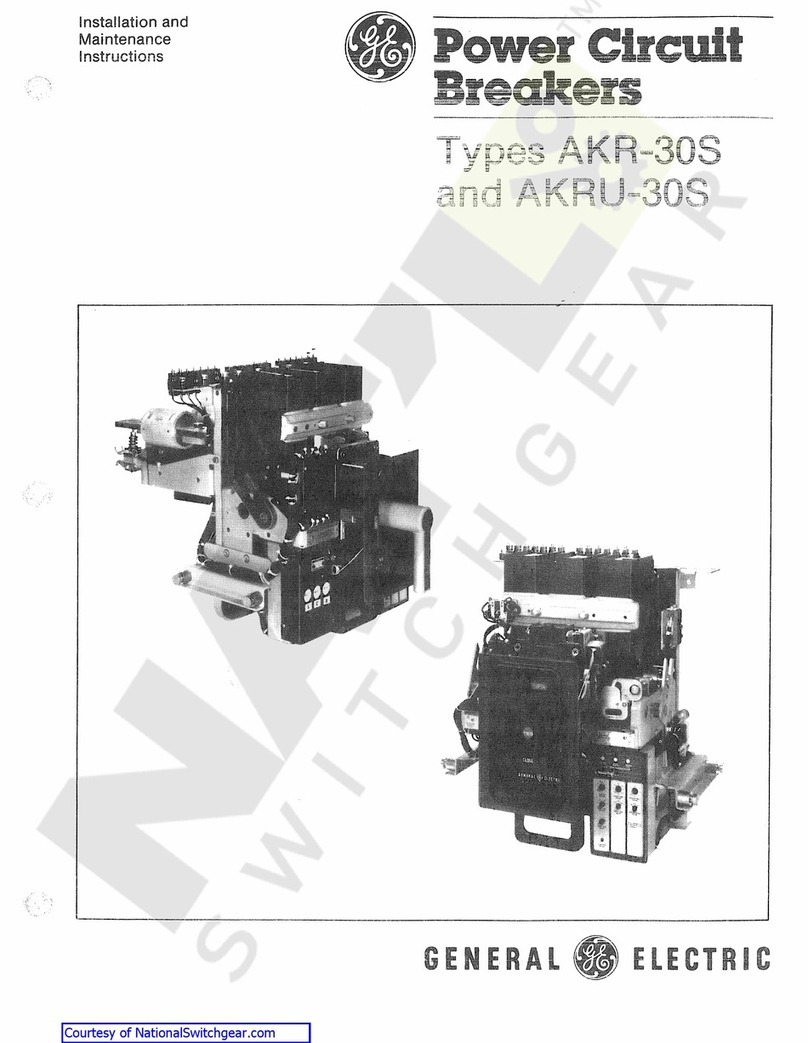

GE AKR-30 Series User manual

GE

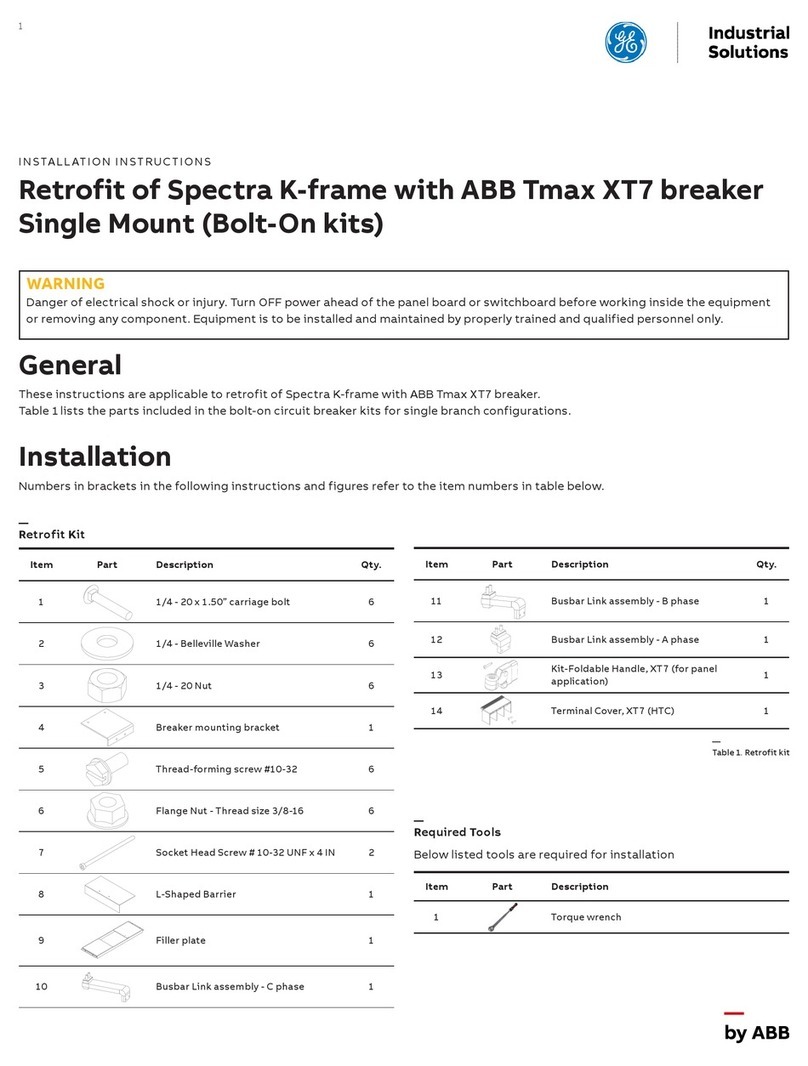

GE Spectra K-frame User manual

GE

GE POWER BREAK MICRO-VERSATRIP E39ME20 User manual

Popular Circuit Breaker manuals by other brands

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

hager

hager TS 303 User instruction

ETI

ETI EFI-4B Instructions for mounting

nader

nader NDM3EU-225 operating instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Gladiator

Gladiator GCB150 Installation instruction