DEH-41304C EntelliGuard® G Circuit Breaker

13 March 14 Table of Contents

©2012 General Electric All Rights Reserved 5

CLOSING PROCEDURE .....................................................................................................................................................................................................21

CONDITIONS WHEN CLOSING CANNOT OCCUR ................................................................................................................................................21

CIRCUIT BREAKER OPENING PROCEDURE.............................................................................................................................................................21

SECTION 5 –LOCKS AND INTERLOCKS

GENERAL INFORMATION ................................................................................................................................................................................................22

CIRCUIT BREAKER FRONT PANEL LOCKING ..........................................................................................................................................................22

Pushbutton Locking ..........................................................................................................................................................................................22

Key Lock for Breaker Trip Free Condition ..............................................................................................................................................23

DRAWOUT CASSETTE FRONT PANEL LOCKING...................................................................................................................................................23

Security Locking..................................................................................................................................................................................................23

Isolation Shutters Locking (If Installed) ...................................................................................................................................................23

Door Interlock Installation .............................................................................................................................................................................24

KEY LOCKS AND INSTALLATION..................................................................................................................................................................................25

TWO-BREAKER CABLE INTERLOCK INSTALLATION ...........................................................................................................................................25

Vertical Mounting...............................................................................................................................................................................................25

Horizontal Mounting.........................................................................................................................................................................................26

SAFETY SHUTTERS INSTALLATION.............................................................................................................................................................................26

Table 5.1: Fixed-Mounted Circuit Breaker Locking...........................................................................................................................26

Table 5.2: Drawout Circuit Breaker Locking.........................................................................................................................................26

SECTION 6 –ACCESSORIES DESCRIPTION

GENERAL INFORMATION ................................................................................................................................................................................................27

INDIVIDUAL ACCESSORIES.............................................................................................................................................................................................27

Motorized Spring Charging Unit .................................................................................................................................................................27

Table 6.1. Motor Operators ..............................................................................................................................................................27

Circuit Breaker Closing Coils –Standard and Commanded........................................................................................................28

Table 6.2. Closing Coil Characteristics .......................................................................................................................................28

Command Operation Module......................................................................................................................................................................28

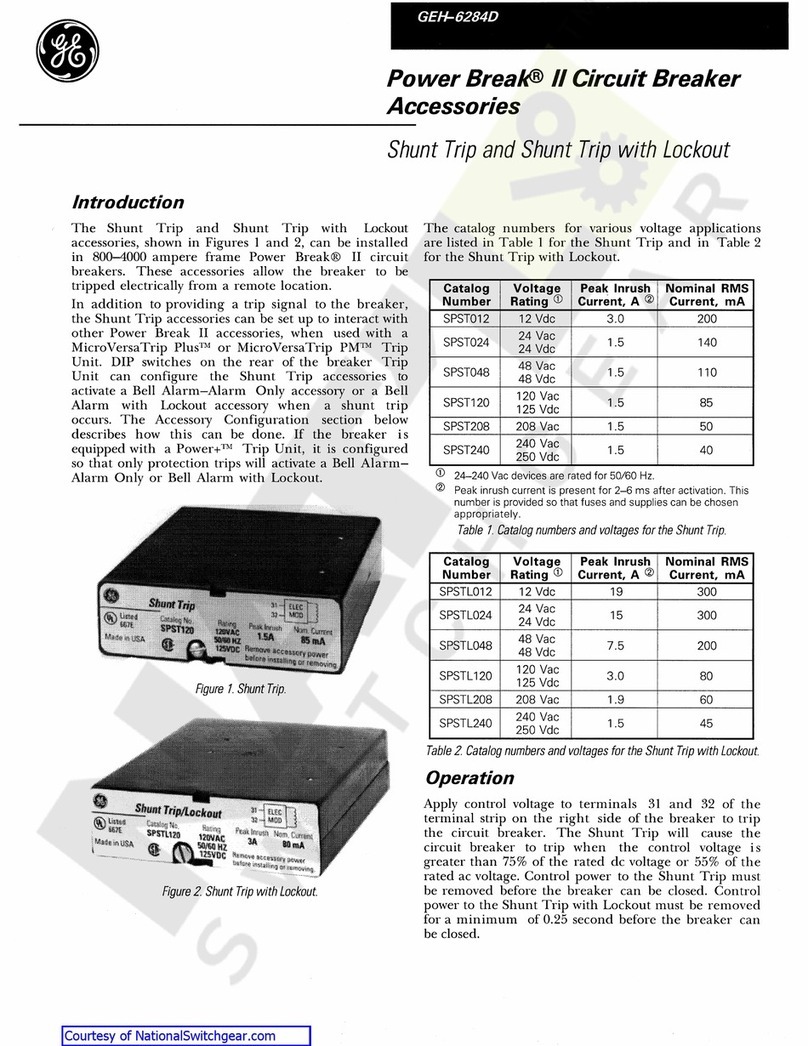

Shunt Trip (ST) ......................................................................................................................................................................................................28

Table 6.3. Extended Range Shunt Trip for UL Ground Fault and ANSI DC Rating Applications ...................28

Status Indication Switch (Coil Signaling Contact)..............................................................................................................................28

Table 6.4. Coil Signaling Contact Module .................................................................................................................................28

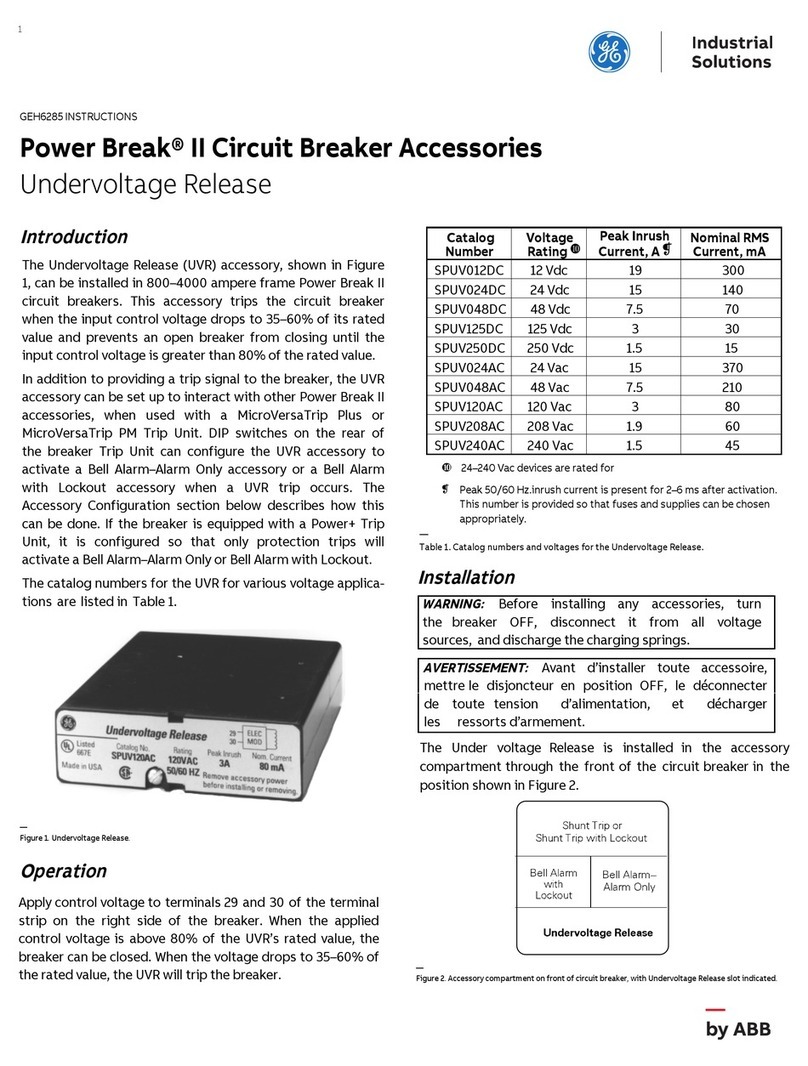

Under Voltage Release (UVR) with Fixed Time Delay.......................................................................................................................28

Table 6.5. UVR Operating Characteristics ................................................................................................................................29

Time Delay Module (TDM) for UVR (Externally Mounted) ...............................................................................................................29

Table 6.6. TDM Characteristics.......................................................................................................................................................29

Remote Operation Coil Combination.......................................................................................................................................................29

Table 6.7. Remote Operation Coil Combination....................................................................................................................29

Auxiliary Switches ..............................................................................................................................................................................................29

Table 6.8. Auxiliary Switches ...........................................................................................................................................................29

Table 6.9. Auxiliary Switch Ratings and Secondary Disconnect Points....................................................................29

Circuit Breaker –Key Interlock Facility....................................................................................................................................................30

Table 6.10. Key Interlocks and Door Interlocks .....................................................................................................................30

Carriage Position Switch (TOC) ....................................................................................................................................................................30

Table 6.11. Carriage Position Switches......................................................................................................................................30

Table 6.12. Carriage Position Switch Ratings (Common NO/NC Contact Configuration.................................30

Mechanical Interlocks (Cable/Rod)............................................................................................................................................................30

Table 6.13. Mechanical Interlocks (Cable/Rod)......................................................................................................................30

Cables.......................................................................................................................................................................................................................30

Table 6.14. Cables for Mechanical Interlocks.........................................................................................................................30

Table 6.15. Interlock Configurations ...........................................................................................................................................31

Bell Alarm with Lockout ..................................................................................................................................................................................31

Bell Alarm Switches...........................................................................................................................................................................................31

Table 6.16. Bell Alarm Switches........................................................................................................................................................31