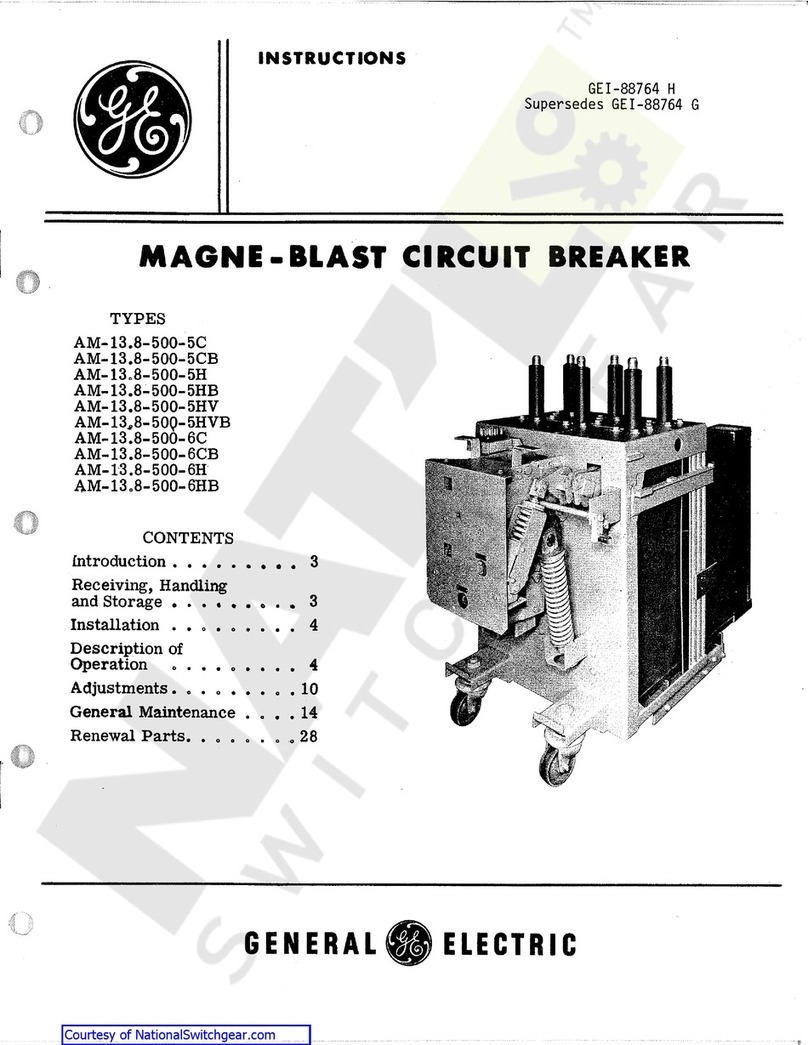

GE Magne-Blast AM-13.8-1000-3H User manual

Other GE Circuit Breaker manuals

GE

GE EntelliGuard L User manual

GE

GE POWER BREAK MICRO-VERSATRIP E39ME20 User manual

GE

GE AK-4-75 User manual

GE

GE SPRCS024 User manual

GE

GE AK-1-50 User manual

GE

GE AK-2-15 User manual

GE

GE Power Break II SPUV012DC User manual

GE

GE PowerVac GEK-86132F User manual

GE

GE SecoVac Series User manual

GE

GE MicroVersaTrip Plus Series User manual

GE

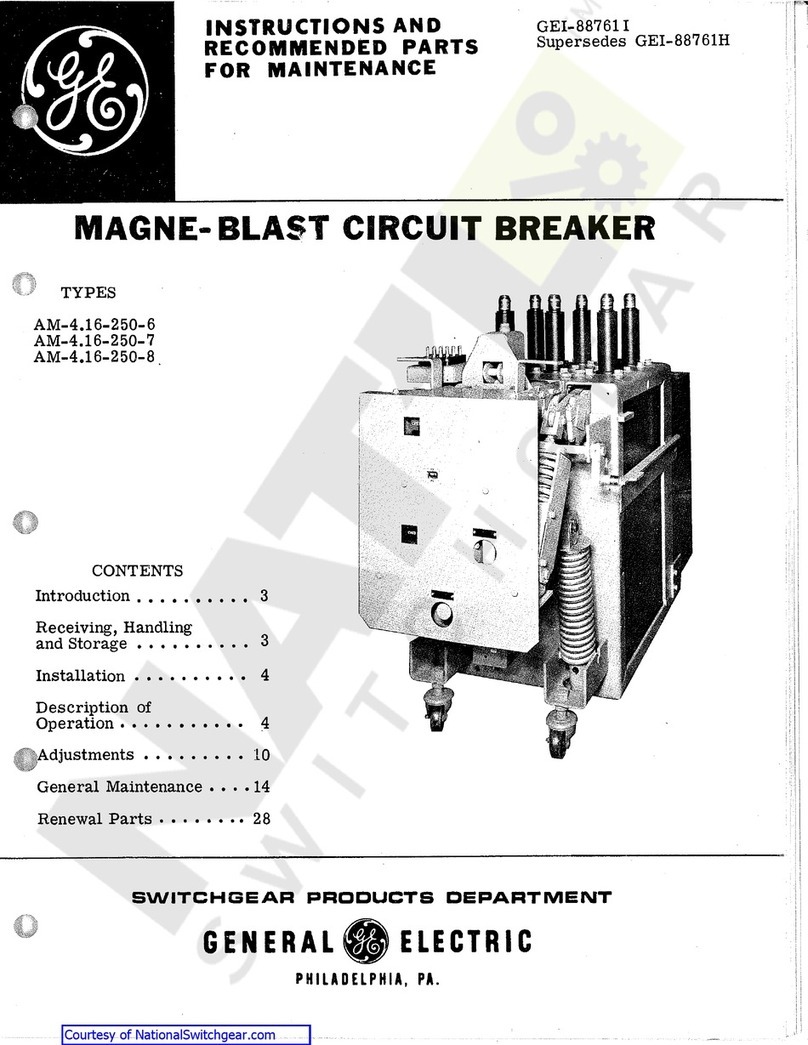

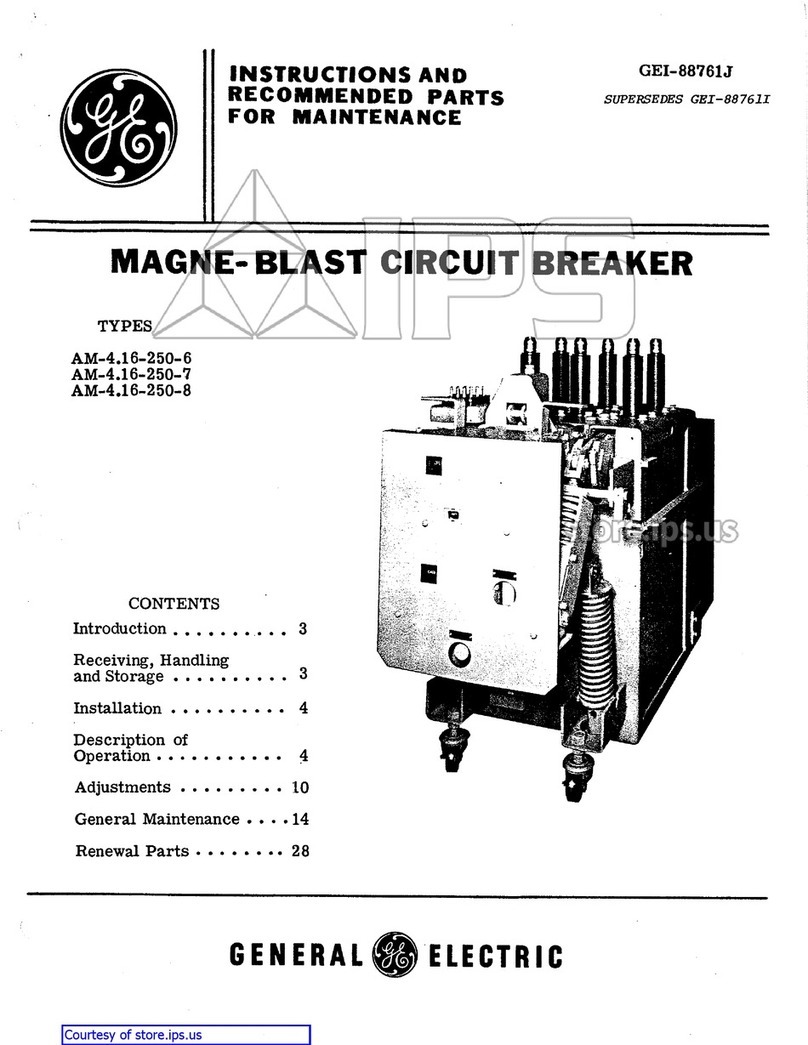

GE AM-4.16-250-6 User manual

GE

GE SD200SA User manual

GE

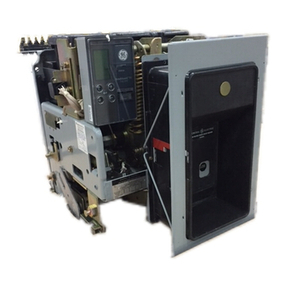

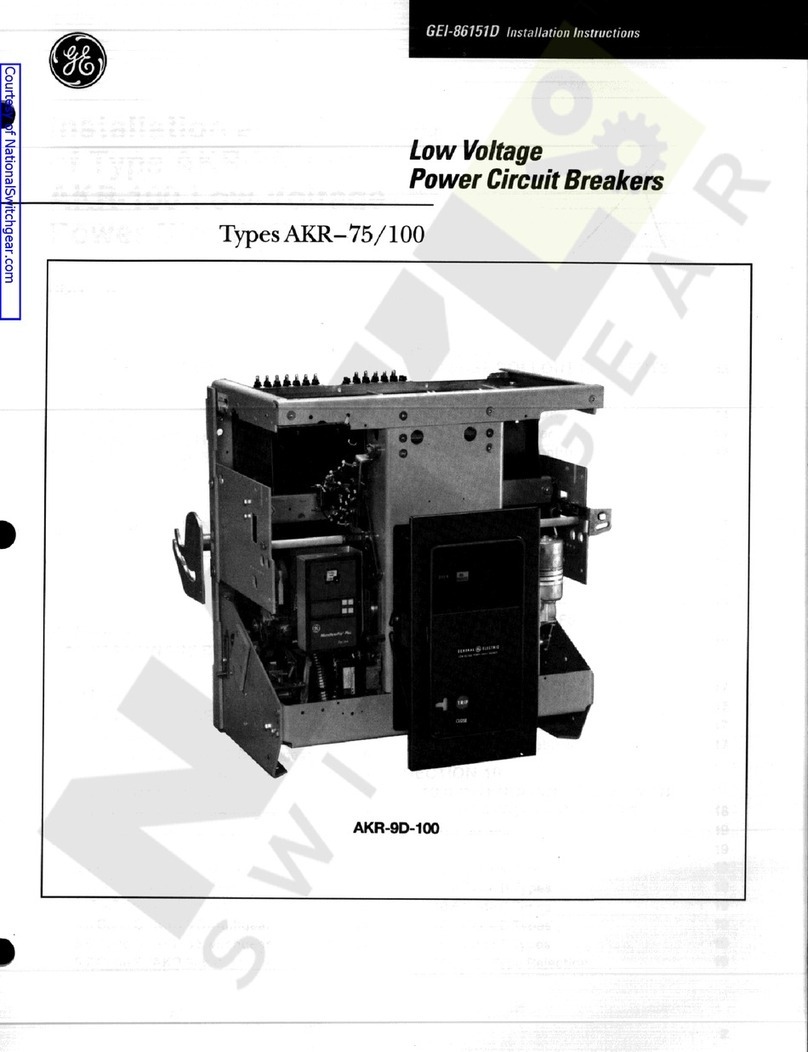

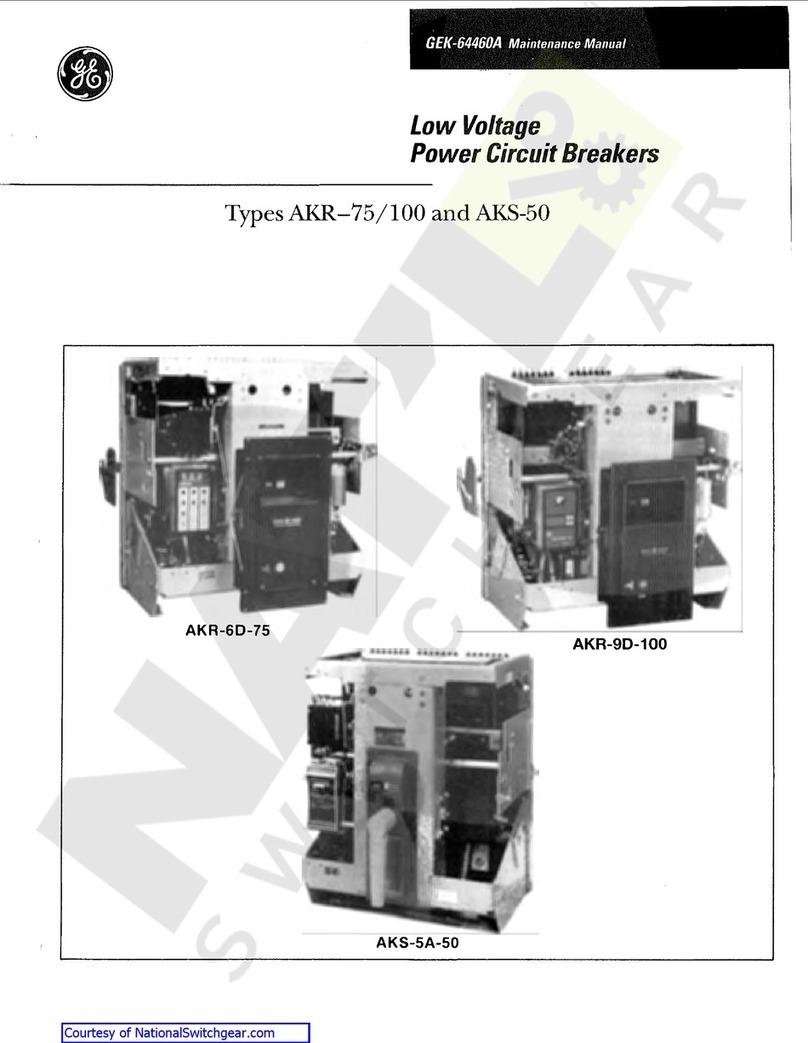

GE MicroVersaTrip AKR-75 User manual

GE

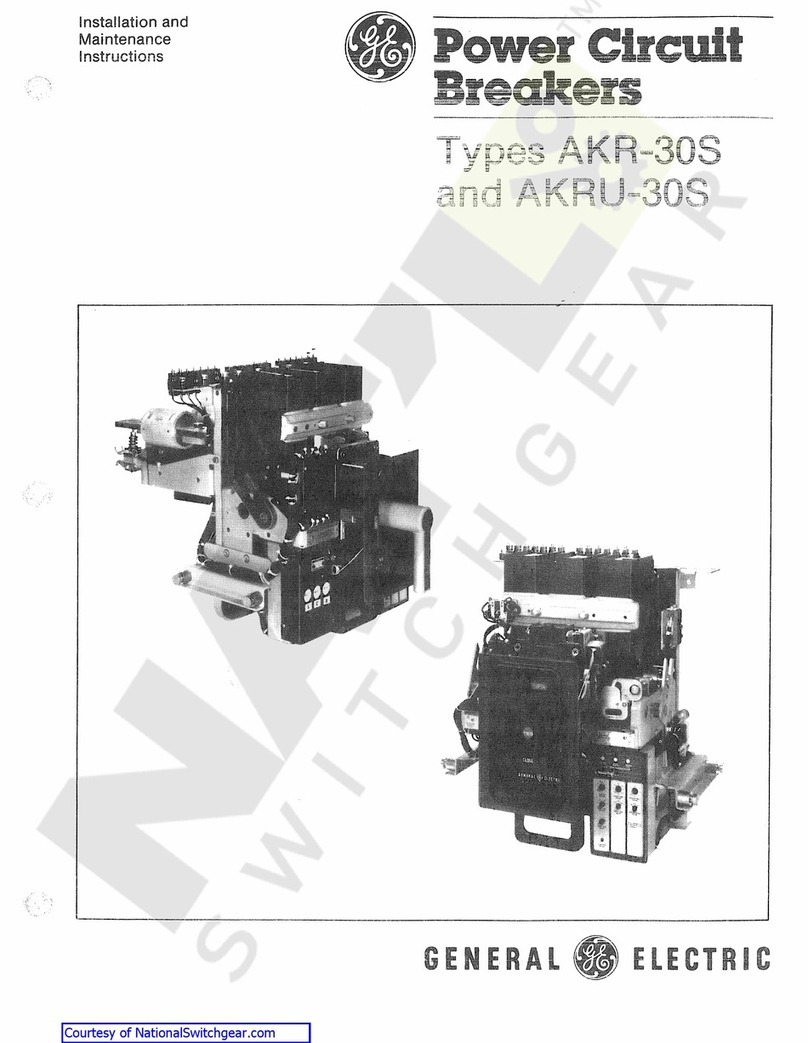

GE AKR-30 Series User manual

GE

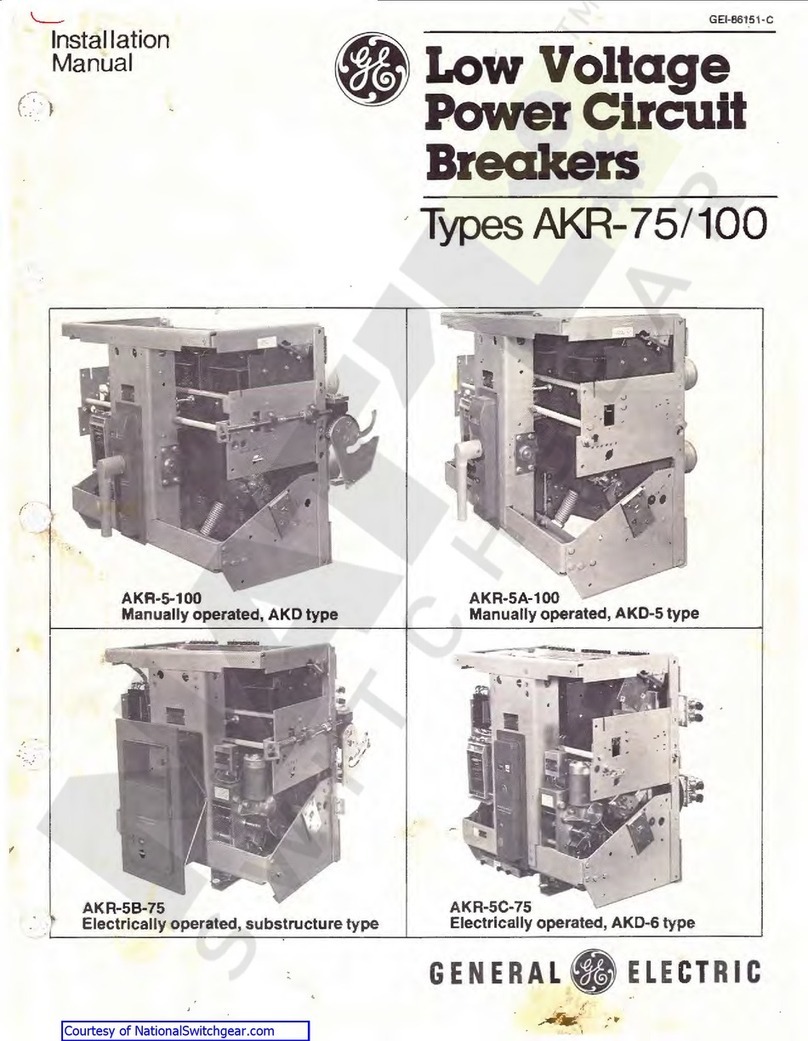

GE AKR-5-100 User manual

GE

GE AM-4.16-250-6 User manual

GE

GE AKR-30S User manual

GE

GE MicroVersaTrip AKR-75 User manual

GE

GE MicroVersaTrip AKR-75 User manual

GE

GE AKR-30S User manual

Popular Circuit Breaker manuals by other brands

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

hager

hager TS 303 User instruction

ETI

ETI EFI-4B Instructions for mounting

nader

nader NDM3EU-225 operating instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Gladiator

Gladiator GCB150 Installation instruction