SR3 SERIES PROTECTIVE RELAY PLATFORM – COMMUNICATIONS GUIDE v

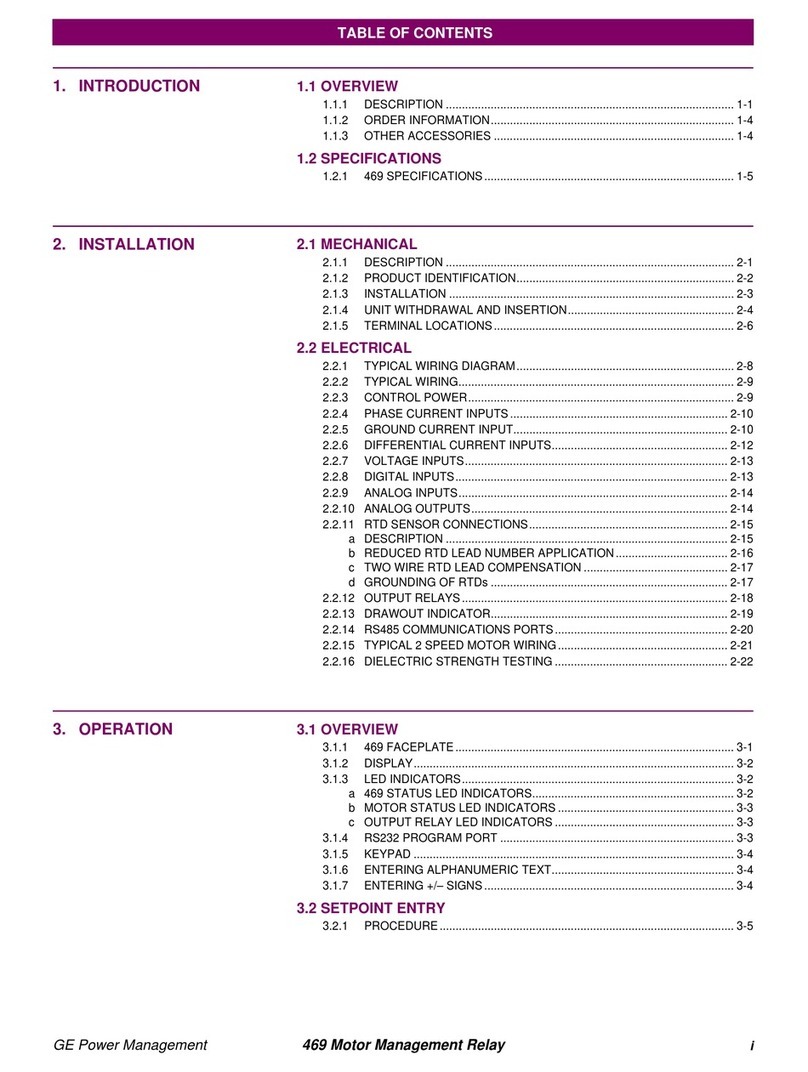

Table of Contents

1. INTRODUCTION Communications interfaces..........................................................................................1 - 1

2. RS485 INTERFACE Electrical Interface.............................................................................................................2 - 1

MODBUS Protocol ..............................................................................................................2 - 2

Data Frame Format and Data Rate.................................................................................2 - 2

Data Packet Format................................................................................................................2 - 2

Error Checking ...........................................................................................................................2 - 3

CRC-16 Algorithm.....................................................................................................................2 - 3

Timing ............................................................................................................................................2 - 4

3 Series supported functions ..............................................................................................2 - 4

DNP protocol settings......................................................................................................2 - 5

DNP communication...............................................................................................................2 - 5

DNP device profile....................................................................................................................2 - 6

DNP implementation ..............................................................................................................2 - 8

DNP serial EnerVista Setup ..................................................................................................2 - 12

DNP general................................................................................................................................2 - 14

IEC 60870-5-103 serial communication .................................................................2 - 16

Interoperability..........................................................................................................................2 - 16

Physical layer ...........................................................................................................................2 - 16

Link layer ....................................................................................................................................2 - 17

Application layer .....................................................................................................................2 - 17

Application level........................................................................................................................2 - 21

Application functions ............................................................................................................2 - 21

Type identification..................................................................................................................2 - 21

Function type............................................................................................................................2 - 22

Information number..............................................................................................................2 - 22

Data management ..................................................................................................................2 - 23

Digital states .............................................................................................................................2 - 23

Measurands...............................................................................................................................2 - 23

Commands ................................................................................................................................2 - 25

103 general settings ...............................................................................................................2 - 25

3. ETHERNET

INTERFACE

350 Redundancy Options ..............................................................................................3 - 1

350 Parallel Redundancy Protocol (PRP) .......................................................................3 - 3

350 High-availability Seamless Redundancy (HSR).................................................3 - 4

350 Daisy Chain........................................................................................................................3 - 5

350 LLA (Link Loss Alert) ........................................................................................................3 - 6

SNTP .........................................................................................................................................3 - 7

SNTP settings..............................................................................................................................3 - 7

SNTP modes................................................................................................................................3 - 7

MODBUS TCP/IP ..................................................................................................................3 - 8

Data and control functions..................................................................................................3 - 8

Exception and error responses..........................................................................................3 - 9

Request response sequence...............................................................................................3 - 9

DNP Ethernet protocol settings...................................................................................3 - 10

DNP communication...............................................................................................................3 - 10

DNP device profile....................................................................................................................3 - 11

DNP port allocation .................................................................................................................3 - 13

DNP implementation ..............................................................................................................3 - 14