www.gemu-group.com 5 / 54 GEMÜ 567 BioStar control

2 Safety information

The safety information in this document refers only to an indi-

vidual product. Potentially dangerous conditions can arise in

combination with other plant components, which need to be

considered on the basis of a risk analysis. The operator is re-

sponsible for the production of the risk analysis and for com-

pliance with the resulting precautionary measures and re-

gional safety regulations.

The document contains fundamental safety information that

must be observed during commissioning, operation and main-

tenance. Non-compliance with these instructions may cause:

•Personal hazard due to electrical, mechanical and chemical

effects.

•Hazard to nearby equipment.

•Failure of important functions.

•Hazard to the environment due to the leakage of dangerous

materials.

The safety information does not take into account:

•Unexpected incidents and events, which may occur during

installation, operation and maintenance.

•Local safety regulations which must be adhered to by the

operator and by any additional installation personnel.

Prior to commissioning:

1. Transport and store the product correctly.

2. Do not paint the bolts and plastic parts of the product.

3. Carry out installation and commissioning using trained

personnel.

4. Provide adequate training for installation and operating

personnel.

5. Ensure that the contents of the document have been fully

understood by the responsible personnel.

6. Define the areas of responsibility.

7. Observe the safety data sheets.

8. Observe the safety regulations for the media used.

During operation:

9. Keep this document available at the place of use.

10. Observe the safety information.

11. Operate the product in accordance with this document.

12. Operate the product in accordance with the specifications.

13. Maintain the product correctly.

14. Do not carry out any maintenance work and repairs not de-

scribed in this document without consulting the manufac-

turer first.

In cases of uncertainty:

15. Consult the nearest GEMÜ sales office.

3 Product description

3.1 Construction

Item Name Materials

1 Pneumatic actuator connection

2 Actuator housing 1.4305

3 Distance piece 1.4404

4 Valve body with leak detection hole 1.4435

5 CONEXO RFID chip

3.2 Description

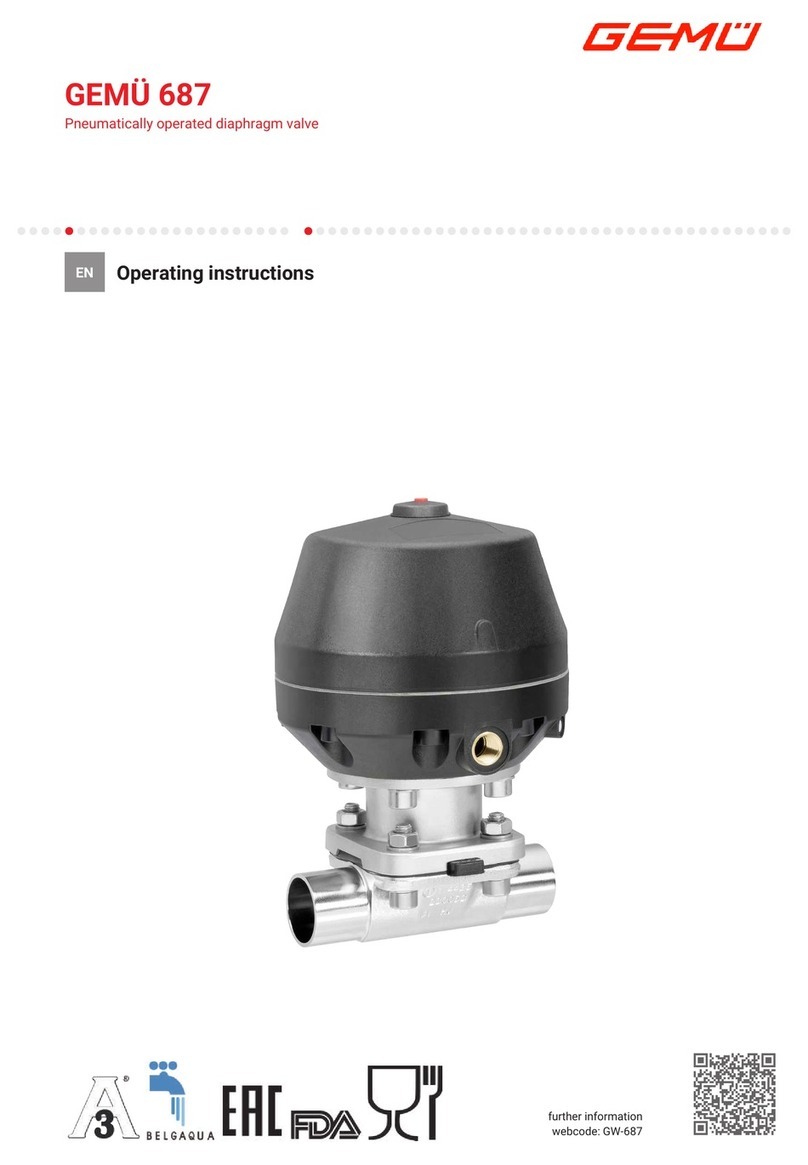

The GEMÜ 567 BioStar Control 2/2-way diaphragm globe

valve is designed for use in sterile applications. Flow rates

range from 80 l/h to 63 m³/h, depending on the version. The

sealing concept of the valve is based on the GEMÜ PD design.

All actuator parts (except the seals) are made from stainless

steel. Normally Closed, Normally Open and Double Acting

control functions are available.

3.3 Function

The product is a pneumatic 2/2-way diaphragm globe valve

made of stainless steel. The GEMÜ 567 2/2-way diaphragm

globe valve is designed for installation in piping systems and

has been equipped with a GEMÜ PD design. Flow rates of

between 80 l/h and 63 m³/h are possible, depending on the

version.

3 Product description