www.gfsignet.com.

Service and Support

Product Registration Form

click here

Warranty Information

Product Registration

Safety Information

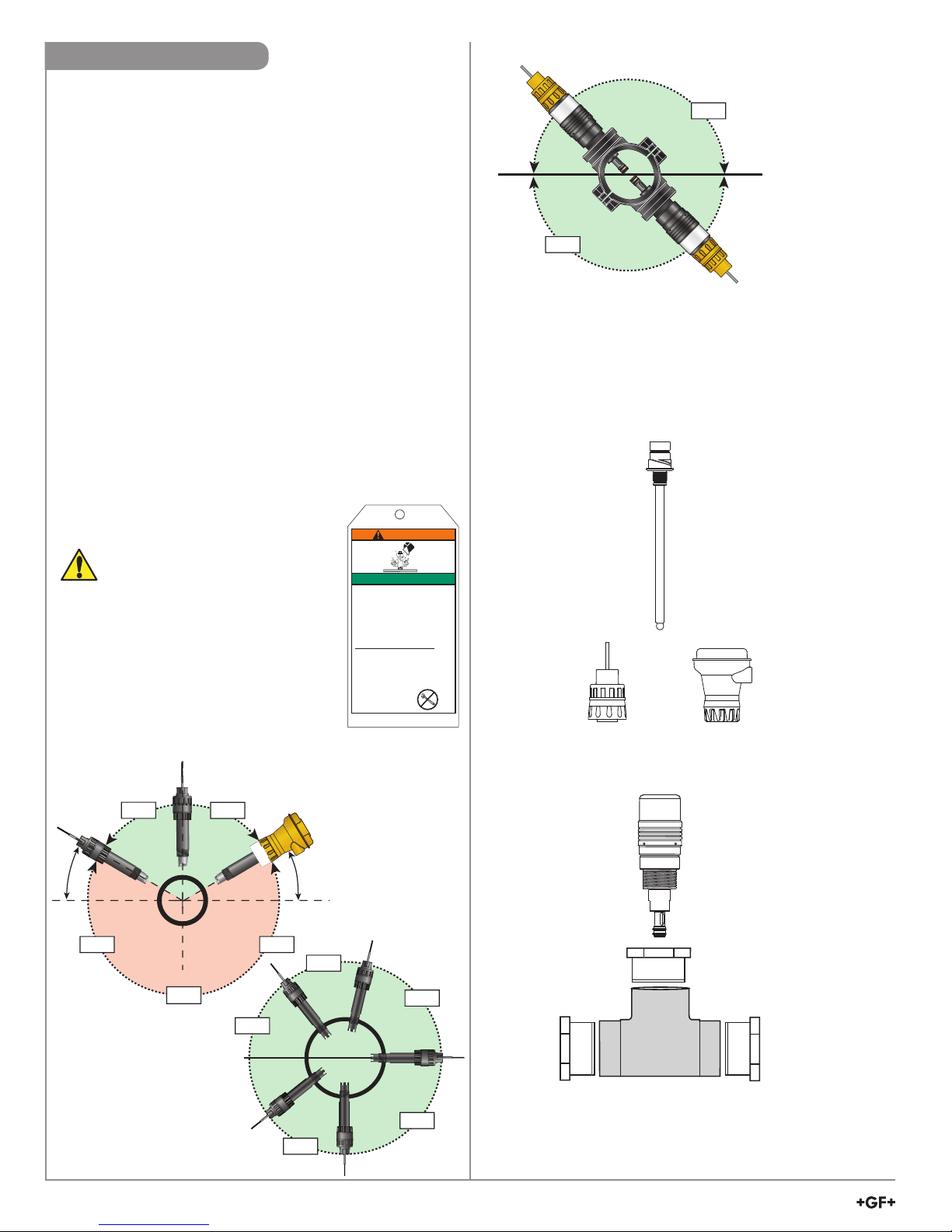

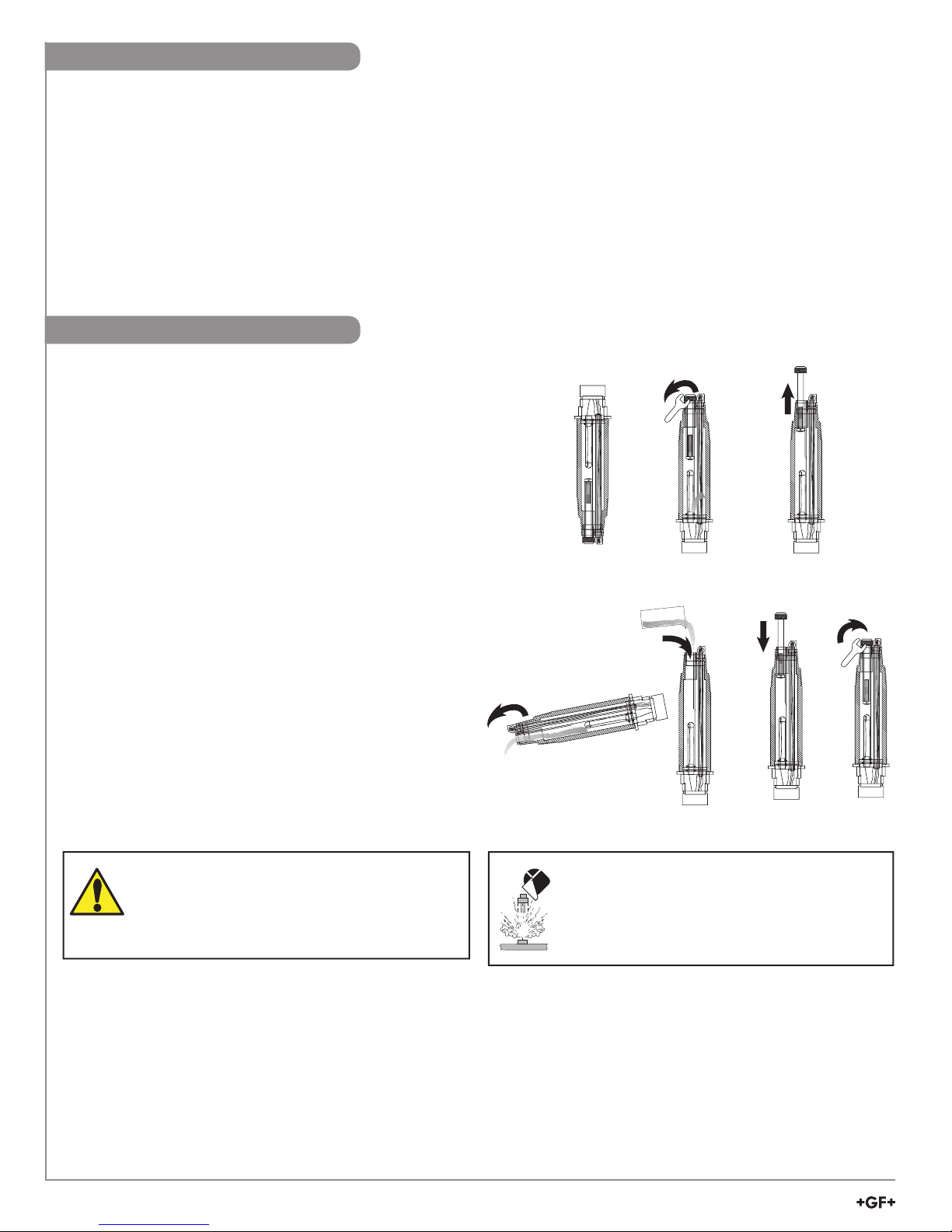

If installing into a threaded connection:

HAND TIGHTEN

DO NOT USE TOOLS

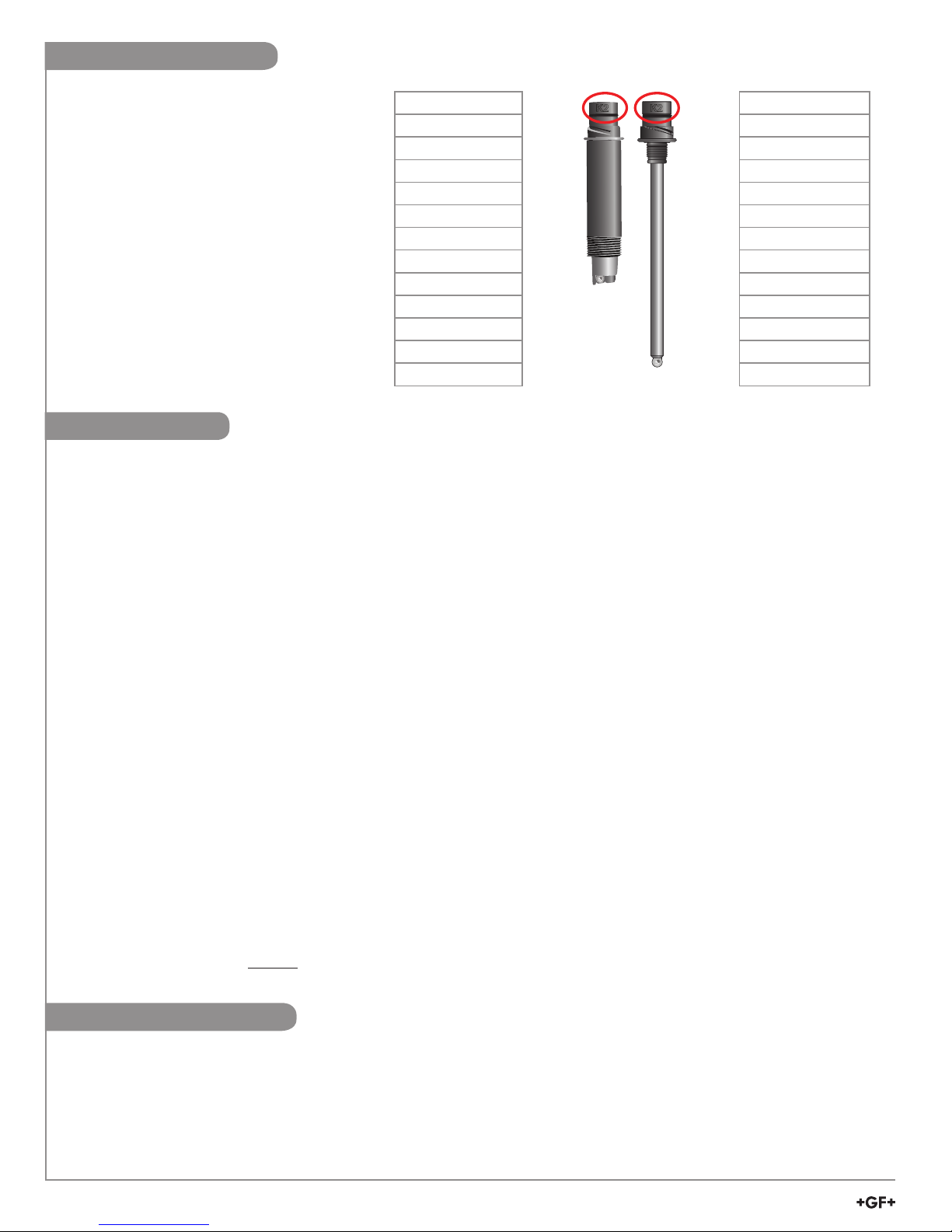

45 mm

(1.8 in.)

43 mm

(1.7 in.)

121 mm

(5.27 in.)

1 in.

NPT

¾ in.

NPT

¾ in.

NPT

32 mm

(1.3 in.)

276X Series

Differential

Electrode

277X Series

Bulb Electrode

277X Series

Flat Electrode

218 mm

(8.57 in.)

35 mm

(1.4 in.)

11.9 mm

(0.47 in.)

Dimensions

Caution / Warning / Danger

Personal Protective Equipment (PPE)

Pressurized System Warning

Hand Tighten Only

Do Not Use Tools

Note / Technical Notes

DO NOT

FREEZE

Do Not Freeze

Chemical Compatibility