26

ENGLISH

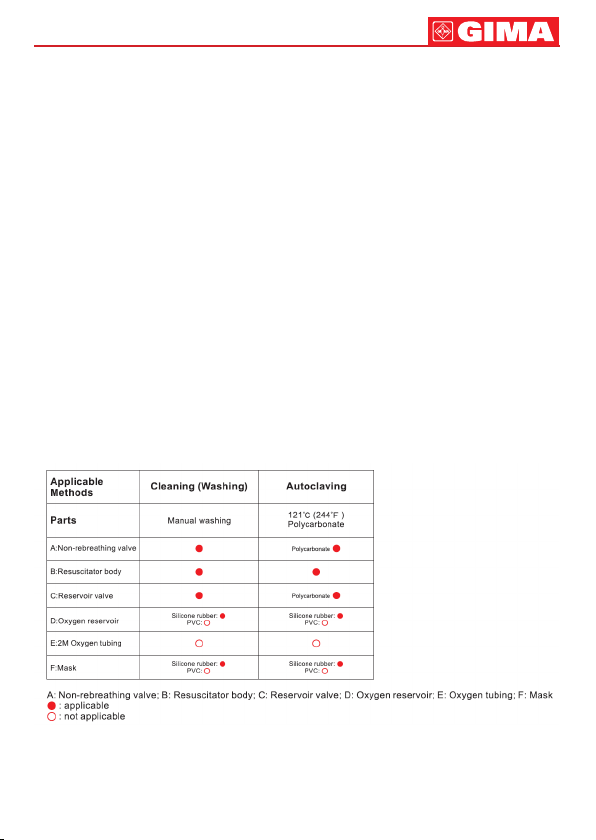

wear and replace them if necessary. Some methods may cause discolouraon of rubber parts

but will not aect their lifeme. In case of material deterioraon, e.g. cracking, the parts

should be replaced. Contact your distributor for part replacement.

3. Assemble the parts following the Assembly View.

4. Aer assembling the resuscitator, a label should be put on to indicate the handling date.

Storage

• For compact storage, e.g. in an emergency case, the inlet end can be pushed halfway into

the bag.

• Never store the resuscitator in a compressed or folded state.

• Never excessively squeeze the bag during storage. When the resuscitator is ready for use it

should not be kept in direct sunlight or in a heated environment.

• Storage temperature: -40°C to 60°C

• For long-term storage or transportaon the resuscitator should be kept in closed packing in

a cool place away from direct sunlight.

TESTING THE RESUSCITATOR

The Besmed Manual Resuscitator should be tested as follows:

• When rst using the new Resuscitator

• Aer cleaning and sterilizing

• Aer any new parts have been ed

• Monthly, if the Resuscitator is not frequently used.

Equipment required: Test lung, 0-100 cmH20 manometer (for Infant and

Child resuscitators only), ow meter, regulated gas supply, gas supply tubing.

Tesng the silicone bag:

1. Remove the non-rebreathing valve and the oxygen reservoir and valve (if ed).

2. Compress the silicone bag and occlude (block) the non-rebreathing valve outlet.

3. Release the bag. The bag should expand immediately and rell. If not, check that the intake

valve at the base of the silicone bag is correctly assembled.

4. While keeping the non-rebreathing valve outlet blocked, compress the bag again. The bag

should not compress easily. If this occurs, check that you are blocking the valve suciently,

and that the intake valve at the base of the silicone bag is correctly assembled.

Tesng non-rebreathing valve

1. Connect the non-rebreathing valve to the silicone bag. Connect the test lung to the outlet

on the non-rebreathing valve.

2. Compress and hold the bag. The non-rebreathing (duckbill) valve inside the non-rebreathing

valve should open and the test lung should ll. If not, check the connecon between the Re-

suscitator and the test lung, and check that the non-rebreathing valve is correctly assembled.

3. Release the bag. The non-rebreathing (duckbill) valve should close and as the test lung de-

ates, gas should ow through the expiratory ports in the non-rebreathing valve. If not, check

that the non-rebreathing valve is correctly assembled.

4. Venlate the test lung for a minimum oen cycles to ensure that the Resuscitator is fun-

coning correctly. Inspiraon must occur when the silicone bag is compressed and exhalaon

when the bag is released. If not, check that the non-rebreathing valve is correctly assembled.

To check the funcon of the pressure relief valve (Infant and Child Resuscitators)

Connect a 0-100cmH2Omanometer to the paent outlet of the non-rebreathing

Valve. Compress the bag. When the pressure relief valve acvates, the manometer should