SN?

hola

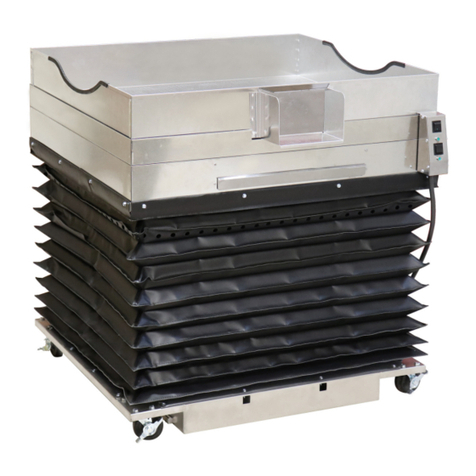

Cernados. °Model Series 2149, 2258, and 2297 (100, 110, and 101, 111) Cy.

Table of Contents

susenpneseausanueassasuseavenssenvavannseusuensorsenserecssousncussnsusauezaveususpsasscoracesnessnsnsnentsesensocosacosecosaveseesveseravocesosssensavesarevensecosacrecesente

SAFETY PRECAUTIONS .ssssccssssscsssssscssssessssscesnsstsssesestenseessssssesarsavseeszacenseeesesceuenssesenssenavevesnsonsearaeasseenearnoneessree d

INSTALLATION INSTRUCTIONS ,....s.00.soususnasaeanensssenssasecnsecessvecursousecaonssceesracsuscusostsosennevseavenseocesanensunsecenaneces5

Inspection Of ShipMENt wcesssessssssnssseseresesessesstssessessssssssnstertsetartseerersieernssneeseestnseneesaeennnasnernsnesnnes 5

Manual ...-cscssssnssssssssossnnsecescscssssaesoassonenesnsssnsessnssssneetnsessessnesenaseevneszseasnnsapnnnannnensnneanaesensaseatsesseensenenevenan 5

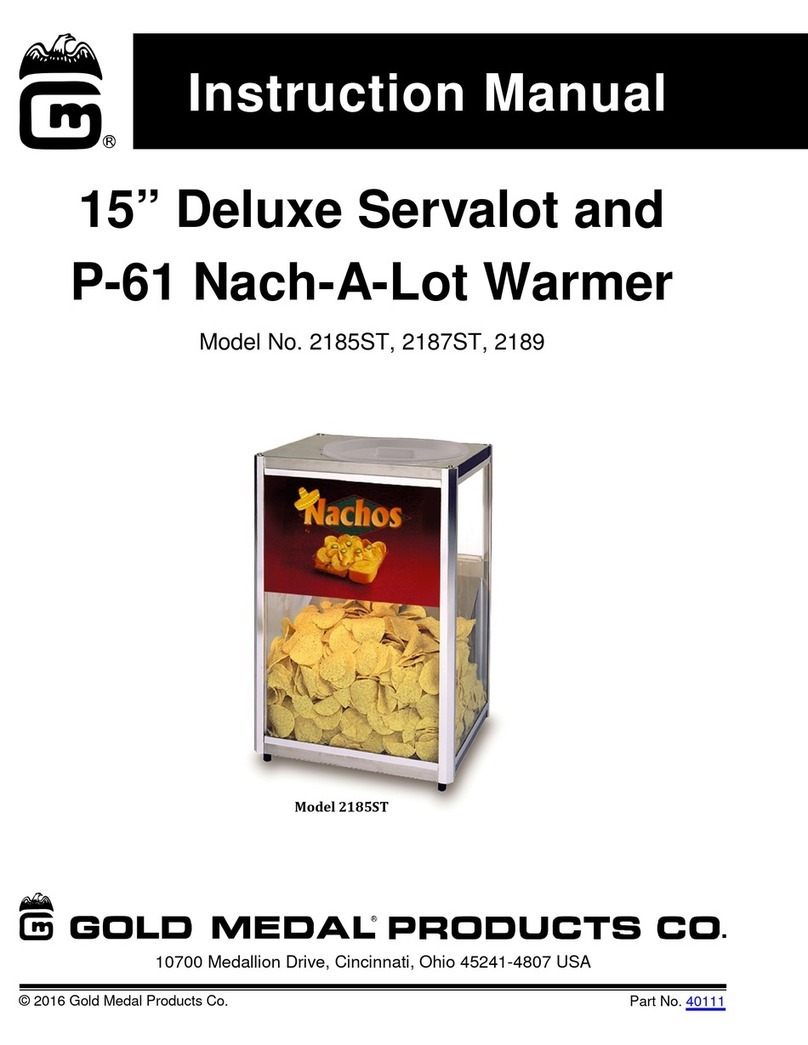

Model Description ....ssssssssssssussssssnassssssssnestenssnssssatessssstssssnstsssesisssasanensesensussssusssussessesesesscnsssssusssssnne 5

Items Included with this Uniteessusssssssssusssessarssssatissnessssutssssssssetssesesunesesuesasessesassseesnese 5

SEtUPaeysessrsaeetsersesnnssnssntieesnessrsesenssessetsnstertnerertastasesestentesseesseennssnenatseesnsnneasnenasenasesanesaneesnnaneneen 6

Electrical REQUIFEMENES oessssssssesssssersesssesnssvssonasesenenaneesnsesnneetnesssanessneenesesvneeseasesnsnsansnseaneaneansuneeeee 8B

Before You Plug In Machine seeessassassssssssssctsesutscrsetisrtsesseiesictsstsssnssussesusiesasistusesusssseseesnssen 10

OPERATING INSTRUCTIONS eccssssssssssnsssssessnsscssssassenscnssevenresnsansentsarernsestssnsnessensiasessonssesecessssesgeeseecs 11

Controls and Their FUNCtIONSsesessssesastssnressesesarteeitusnstutuinumuiusasisiisistiieseseseesseees 11

Program the E-Z Set Timerascsscccssssssssssssssscceresnesasaasevuseaveveseccssesensssonntosceassuvesuaseososzensescesnenesenesvesreczase 14

Popping Corn Instructions.............Sousoueearsnsasensouuseconseesevecnoceseessesaeesevaronsacuaccossessossassoesaacasncesencesseazrensezes 15

Care and Cleaning «ssssecsssssssessccssssssssssssssissstsssssestensesesensesscosssseaesevsrnsucesuaceasersscenssncsesssuesseressesensucsecenaracvess 17

Troubleshooting .-ssscsssssnssunseseeesarsssssssessssenssuasessassssasesnatsnasseteersensatenistsanastsniussessessccessesesscg, 20

MAINTENANCE INSTRUCTIONS ssessssessscsrsesssetssessssseseessserstssstesstrstenetennssanareatntesiusssseseesessescoes22

Removing Agitator Assembly and Shaft Maintenance scsssssesssssusssnseseesteseressseoescs.cc,enenssens 23

Replacing the Packing Cord on Kettle HUD..sssssesssssssssssessaretssssstsnmttnuststtssusseesesecc..., 24

Kettle and Drive Shaft Alignment...sscssssssessssussasssusssuesensetsiarsttetinttimattinuttinuseesoesccc.,., 25

Electronic Temperature COntrOle.essessssantssasssssasseinsuaenarsnarenessinsitnastittieeseocc,., 26

Operation .erssumenmennneneensienenaeisninenettttsiineenaenminiintuniitiiueeseeeses.. 26

Control Description sermsemmmentemsnmiunsnnineenteneiieinunneenuniiuninitieecccc.., 26

Programming the Electronic Control .asmsmunnnmntsnustinsinsinueinmunniiniiiieececccc., 27

Error Conditions for the Electronic Control -smssusmutnusinnnennanninunitititeeecccc.., 28

Kettle Circuit Breaker..sssssssssssssnsnssssscomnsssesssnssssssssessssnsssessussessessestssssuasnteesessessseees.,sessensserssore 29

ORDERING SPARE PARTS.ecssssssssscssscessssssecassscerseavessessuavovanencenennecenscncnsauensacencoseususnesesnentaressessensnestonseccreresenee 30

Unit Exterior ?Front View ?Filter..esmsmumunninennnnetntineuninnuiiiiniuieceeeec., 31

Unit Exterior ?Kettle Mount ~Parts BreakdoWNmessunenssnninuninasutsniiiinieneescc, 33

Kettle Assembly (36, 48, and 60 02.) ~Parts Breakdown susnnnttuntinuteeeeeeec..., 35

36 02, Kettle Bottom ?Element VieW.oemmunmnnnnntnsinsnnenananansitinininuueeseeesc.., 37

48 02. Kettle Bottom ?Element VieWeesumutmnsaianenetstnansnasineniunniniiupeieseec., 38

60 02. Kettle Bottom ?Element VieW..sssersessanaunnienssnenestenatuntriiniinunneeeseseec.., 39

Pedestal Interior ~Motor and Shaft .ecsssnmssmnsusisieeesnueinunneeneauitiiniupiueceees.., 40

Pedestal Interior ?Electrical ?Parts Breakdown ssessssmensninsnnnienentisniiuneeeececs, 41

Control Box/Control Panel ?Parts Breakdown sssnnenninuenunnunenutiettsupeeeeeeee., 43

Safety Labels crrsssssreeneenetnseneenerneesenttaerreneenrsasantesanssnterssttsnustiatestssissististsintiatisiisuetuesneseeeeee 44

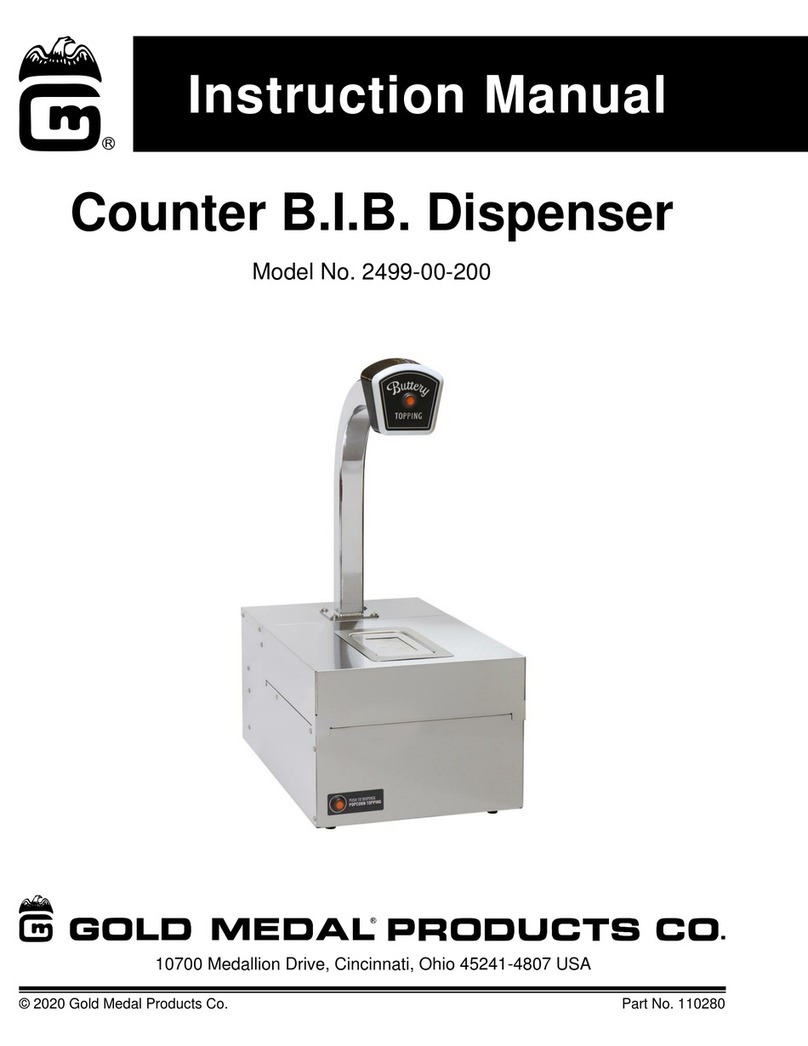

ACCESSOTIES svsesssseseernsernercornetnternenssnnsoanneneaneenstntenneeeeeesseeneeusstastnestsntissiaatiestttstiasiueiusieseceesese, 45

Wiring Diagram sesssssssssssseseennennsensussconsonsssonssssssesrasessanessserseuessnenesevesuecrsossesunrocssseaesesesesvvseussesuueseueerssenns 46

WARRANTYvessssessrscevssesressesseoesscsnsouserssesnenussesnssecsnsonsonesseveocouaussnsustouasansssncassesesonseoressoresonssesserscosssszesascenseseseaneons 47

SS Page 2°~ gmpopcorn.com