LL

ODELS

and

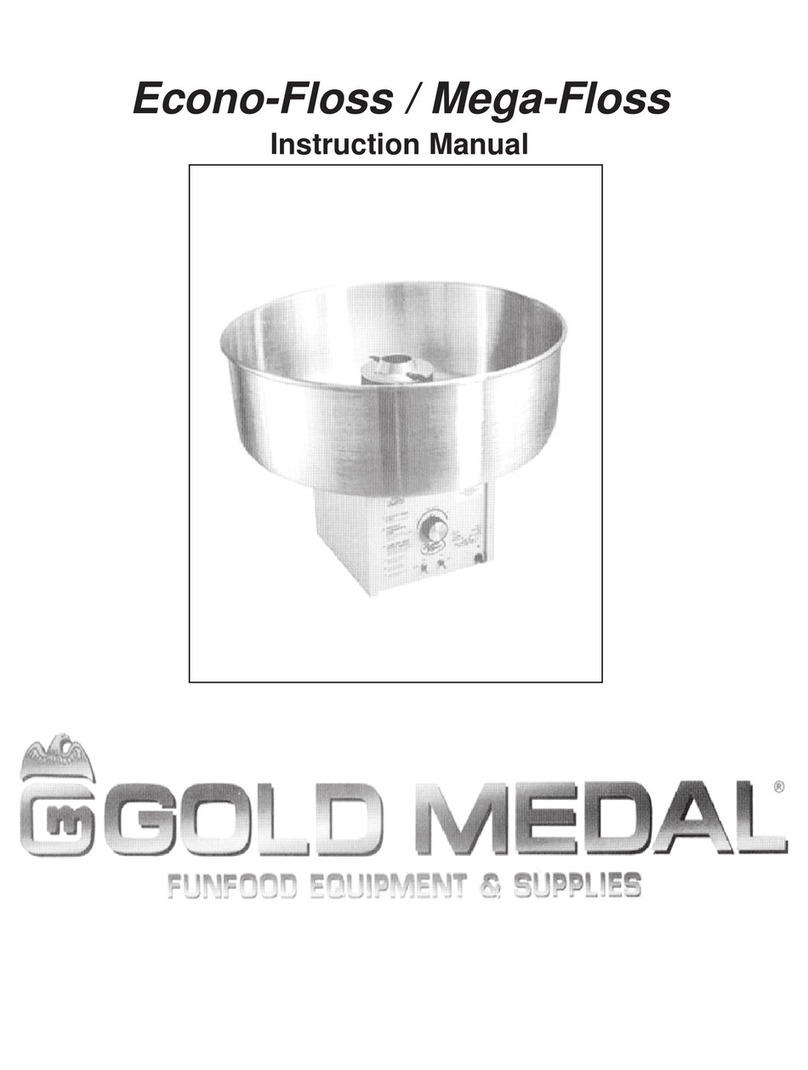

MAKING FLOSS

1. Before operating your machine, read this section on how to make floss.

2. Using a damp cloth, moisten the inside of the floss pan. This will cause the floss to adhere to

the sides of the pan. The Whirlgrip Floss Stabilizer Model No. 3010 works more effectively to

prevent floss from leaving the pan and is offered by Gold Medal at a modest price. See the

illustration on page 6 which shows proper installation of the Whirlgrip Floss Stabliizer.

3. After reading this entire section, operate your machine as described in the operating

instructions for your machine following this section.

4. Pay attention to the direction of the floss as it is spun out of the head. It should be thrown

against and adhere to the sides of the floss pan. Attached to the top plate of the spinner head

are two floaters, these give additional air current for floss control. By twisting the leading edge

of the floaters down, you get more lift and the floss will go upward. With the leading edge up,

the floss will go down. A little practice should give you good control in any climatic condition.

5. To pick up floss: Once you practice awhile, anyone can be an expert at rolling the web of

cotton candy onto the cone. First, pick up the cone. If it sticks in the stack of cones, do not

pull, but twist it off the stack. Hold an inch or two of the pointed end of the cone between your

two fingers and your thumb. With a light flicking action, break the web of floss that is building

up in the pan. Usually some floss will stick to the cone. Lift up the cone with the ring of floss

attached and, by rotating the cone, wind the floss onto it. Do NOT roll floss onto the cone

while it is inside the pan. This will just pack the floss onto the cone, causing you to use more

floss to fill the cone, and result in less cones of floss per load of sugar. For additional help,

reference Floss Making Procedures section.

If you experience difficulty in getting the floss to stick to the cone, it will be helpful to pass the

cone over a damp sponge. One pass over the sponge should cause the floss to stick, allowing

easier floss pick-up. Many experienced operators prefer to lift the ring out of the pan and, with a

flick of the wrist, turn the ring into a figure eight and whip it around the cone. This leaves giant air

pockets and makes it appear that you are serving a larger portion.

Shut Down Procedure

When completing operation for the day (or any prolonged period), run all the sugar out of the

floss head. When empty, turn the heat to highest position for approximately one minute to

“clean” the band by baking off remaining sugar. NEVER put water in the floss head.

Cleaning Instructions

Machine must be properly grounded to prevent electrical shock to personnel.

DO NOT immerse in water.

Always unplug the equipment before cleaning or servicing.

025_020314

Burn Hazard. DO NOT touch spinner head. Allow to cool before cleaning or

servicing. Avoid contact with molten sugar.

006_010914

Unplug the machine and wait for the floss head to cool down to room temperature. Wipe all

surfaces with a clean, damp cloth. Make sure all parts are dry before resuming operation.