Floor Ceiling Air-Conditioning Unit

8

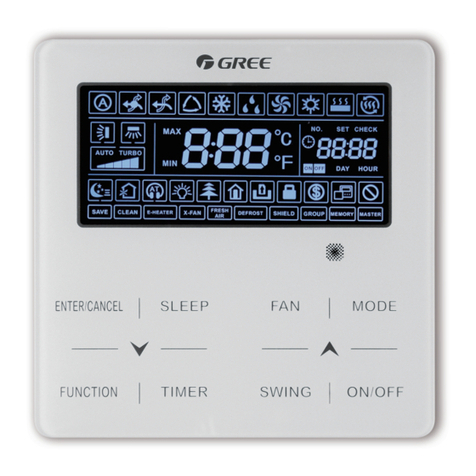

(1) Interface of the Power Supply

a. The interface CN1 of the power supply module board is for the connection board of the

external power cord, the terminal AC-N for the neutral line, the terminal AC-L for the live line and

the middle terminal keeps open.

b. The interface CN4 of the power supply module board which is for the power supply of the

display board, is connected with the interface CN1 of the display board through the two-core wire

provided by Gree.

(2) Communication Interface

The interfaces CN2, CN3, CN4 and CN5 of the display board are for communication, and CN2

namely COM4 is for the communication o the duct type unit (2-pin); CN5, CN4, CN3 namely COM1,

COM2, COM3 respectively are for the communication of the multi VRF system (3-pin).

5.1.3 Preparation and Connection of the Communication Line

a. The communication line between the centralized controller and the unit should be prepared

by the user according to the actual project.

b. Preparation and connection of the communication line for the multi VRF system

①One three-core communication line is needed to connect one set of multi VRF system to

one interface (COM1, COM2 or COM3) of the smart zone controller.

②One end of the communication line is connected with the smart zone controller and the

other is connected with the three-pin socket of the indoor unit.

c. Preparation and connection of the communication line for the duct type unit

①The communication line for the duct type unit is the two-core line provided by Gree (one

end is the two-core head and the other end is the crystal head, code: 40113325)

②Where there are N sets of duct type units, then N+1 communication lines are needed.

③Connect the two-core head of one communication line to the port COM4 of the smart zone

controller and connect the two-core heads of N communication lines to the two-pin socket

of the wired controller of the duct type unit.

④The user can prepare the extension line and connect the wires inside the crystal head

according to the actual need.

Note: one set of Multi VRF system consists of one multi VRF outdoor unit and one or more

than one multi VRF indoor units. And one set of duct type unit consists of one duct type outdoor

unit and one duct type indoor unit.

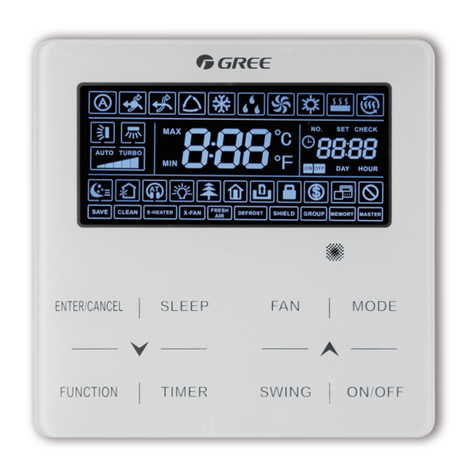

5.1.4 Installation

The installation can proceed on when the installation location is selected and the installation

steps are as follows:

a. Firstly make sure where to install the smart zone controller.

b. Embed the power supply box (2) as Fig.4.6 for the installation of the bottom case (3).

c. Connect the power cord and the communication line of the display board and then let both

go through the power supply box (2).

d. Fix the bottom case on the power box (2) by screws.

e. Tidy up the power cord and the communication line inside the smart zone controller.

f. Close the cover (5)