© Guldmann GB/US-09/2016 • #550376_3

4

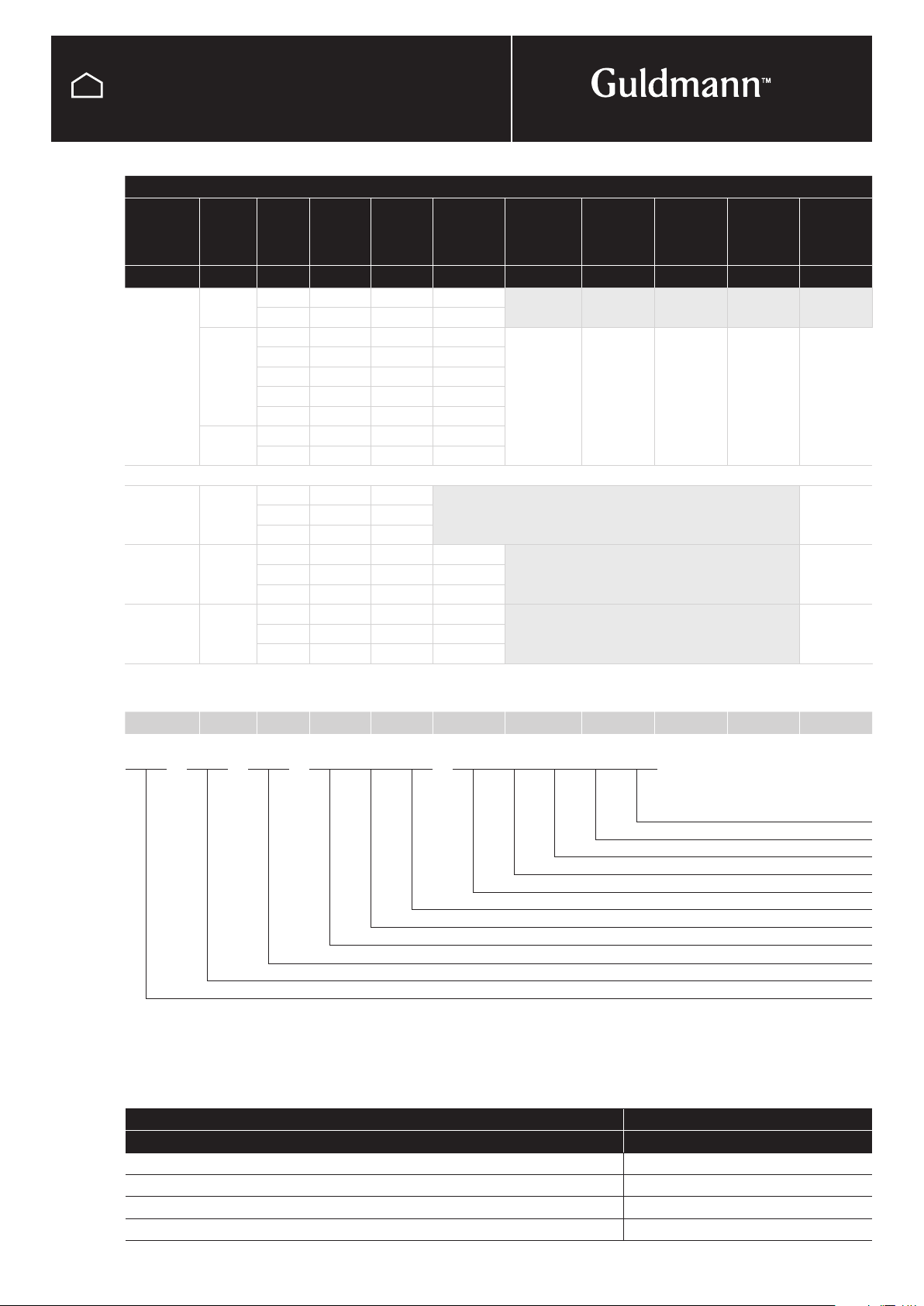

GENERAL INFORMATION

General conditions ................................6

Key to symbols and general information ...............8

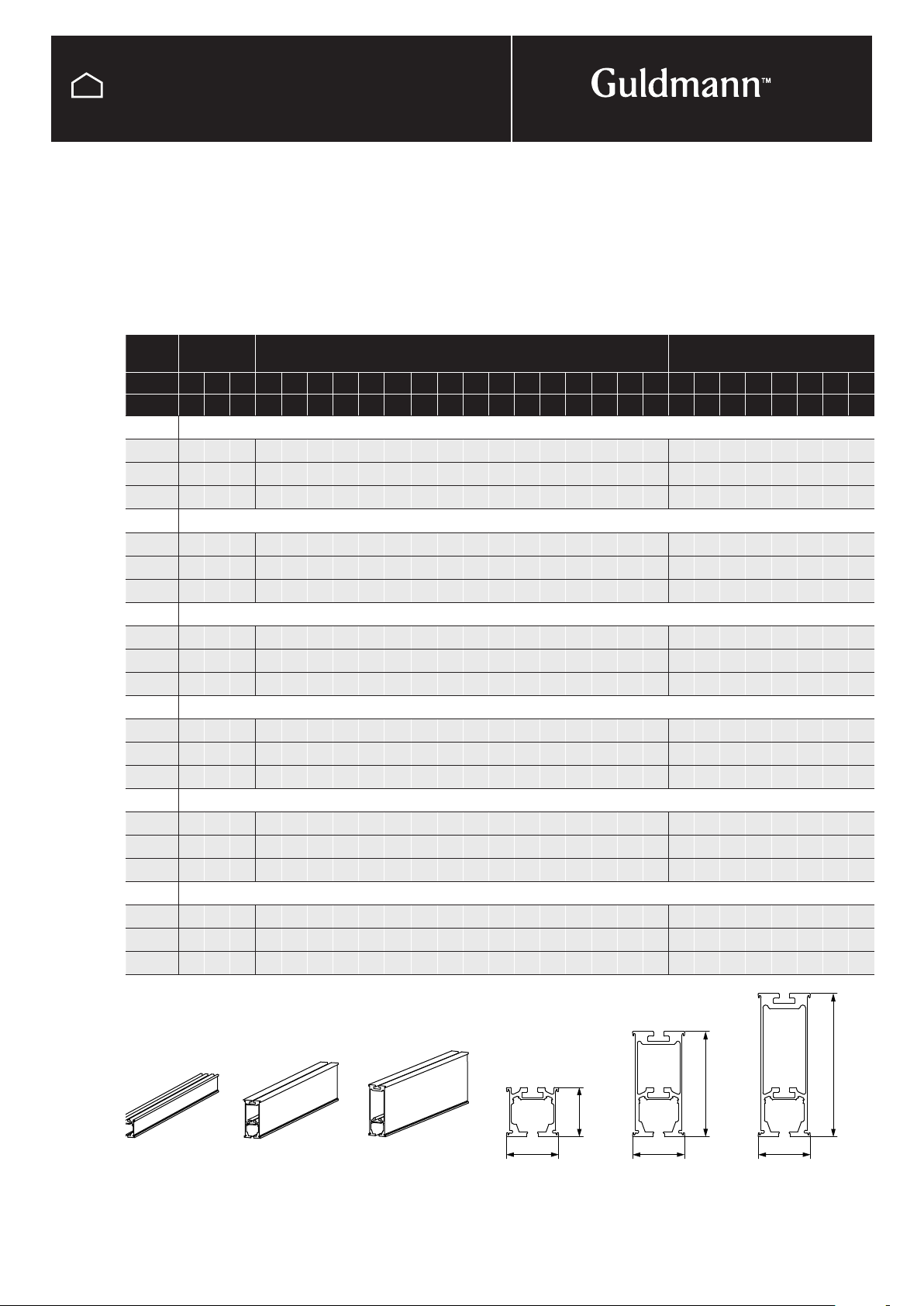

GH lifting modules, configurations ....................9

Types of rail .....................................10

GH3 & GH3+ .................................10

GH1 ........................................11

Technical specifications ...........................12

GH3 and GH3+ ...............................12

GH3 Twin ....................................13

GH1 ........................................14

GH1 F .......................................15

GH1 Q ......................................16

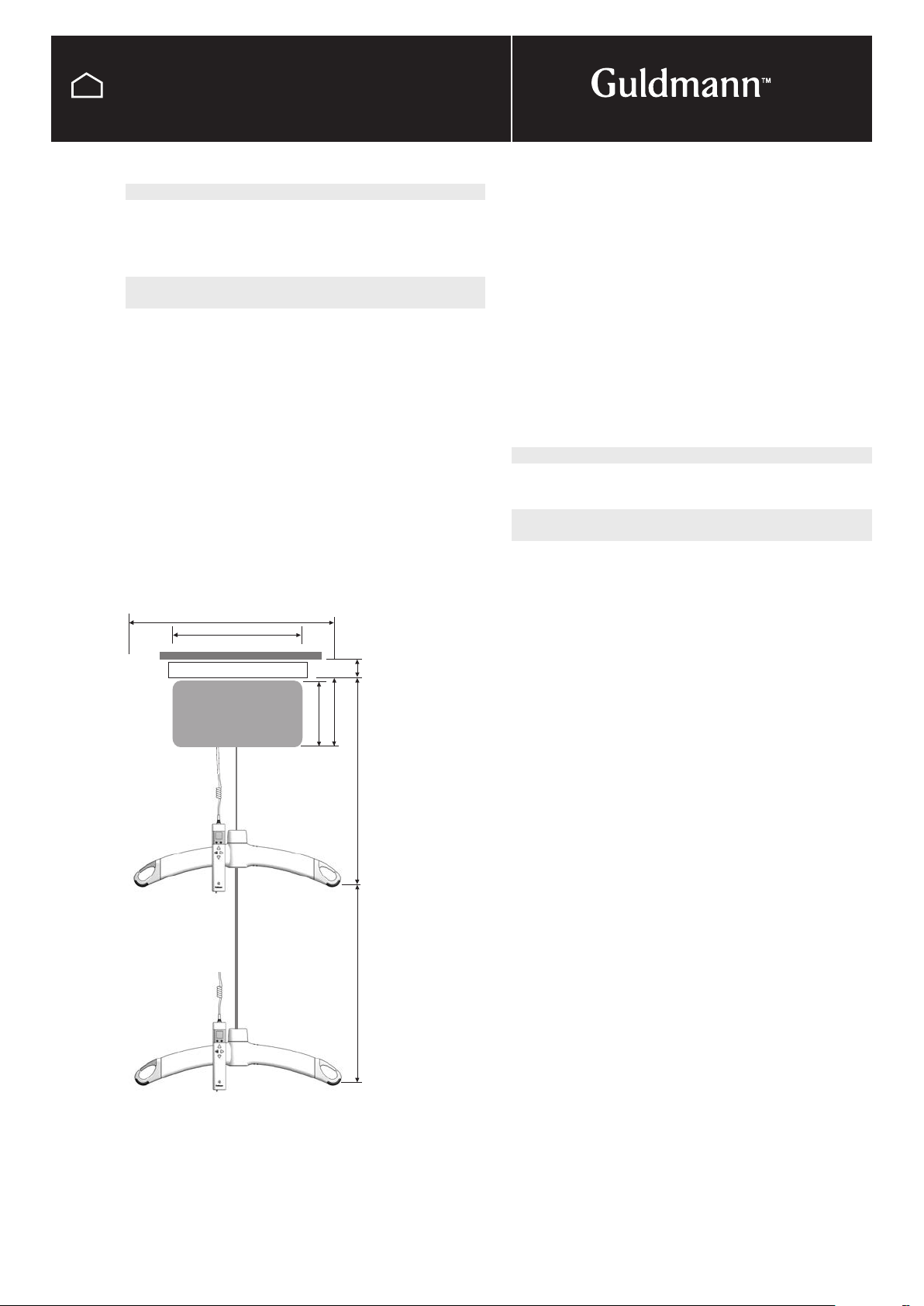

Trolley and Transport trolley for GH1 F .............17

Power supply....................................18

Electrical installations

Protection against electric shock ....................19

SERVICE AND REPAIR

GH3 ..........................................24

Before service or repair starts ....................24

Removing side covers ..........................25

Removing hoist from trolleys .....................26

Replacement of batteries - 1 drive belt .............27

Replacement of batteries - 2 drive belt .............28

Replacement or adjustment of hand control.........29

Replacement of lifting strap ......................32

Replacement of timing belt ......................35

Removing covers ..............................36

Replacement of safety control mechanism ..........38

Replacement of belt drive .......................39

Coating at GH1/GH3 during annual inspection.......41

Replacing or adding PCBs ......................42

Replacing the leader motor safety PCB ............43

Replacing the Auxiliary motor PCB ................45

Replacement a Communication PCB ..............46

Replacement of charger PCB ....................47

550548_01 Motor safety 2010 PCB, spare part ......48

550550_00 Communication PCB, addition ..........53

552714_01 Motor AUX, Spare part ................56

Wi-Fi PCB, Spare part ..........................59

WiFi sequence ................................60

WiFi description ...............................61

Installation of Wi-Fi PCB.........................62

Adjusting the bottom cover ......................64

Product and Wi-Fi Label ........................65

Upgrade GH3+ ...............................66

Cover cut-out instruction ........................67

GH1 ..........................................68

Before service or repair starts ....................68

Removing the side covers .......................69

Removing the Trolleys, GH1 & GH1Q ..............70

Removing top assambly, GH1F...................71

Removing the hoist covers.......................73

Replacing Battery ..............................74

Replacing the lifting strap .......................75

Replacing the Hand control ......................77

Replacing safety control mechanism...............78

Replacing the timing belt ........................79

Replacing belt drive ............................80

Replacing the charge PCB.......................81

Replacing the Motor safety PCB ..................82

Instructions for installing PCB and Battery unit .......83

GH1 F Trolley recomendations ...................89

Battery storage NiMH .............................90

IR remote control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Guidelines for troubleshooting ......................95

GH Combi lock ..................................98

Combi lock 3...................................103

Installing non-fric tape, fixed part.................109

Switch track GH ................................110

End stop ......................................125

Swivel assembly instruction .......................126

TECHNICAL DRAWINGS

Spare part overview .............................128

GH3+ .....................................128

GH3 .......................................130

GH3 twin....................................132

GH1 & GH1 Q ...............................133

GH1 F ......................................135

Wiring Diagram .................................137

GH3 200 kg & 250 kg .........................137

GH3 200 kg & 250 kg drive .....................138

GH3 Twin 250 kg & 500 kg .....................139

GH3+ 200 kg & 250 kg ........................140

GH3+ 200 kg & 250 kg drive ...................141

GH3+ 200 kg & 250 kg drive WiFi ...............142

GH3+ 300 kg, 350 kg & 375 kg drive .............143

GH3+ 300 kg, 350 kg & 375 kg drive WiFi .........144

GH3+ Twin 250 kg & 500 kg CLM ...............145

GH3+ Twin 250 kg & 500 kg load cell ............146

GH3+ Twin 250 kg & 500 kg CLM WiFi ...........147

GH3+ Twin 250 kg & 500 kg load cell WiFi ........148

GH1 .......................................149

GH1 F ......................................150

GH1 Q .....................................151