4

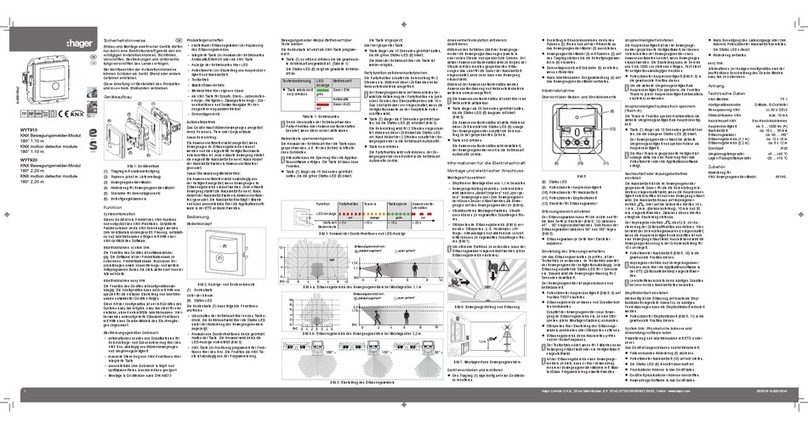

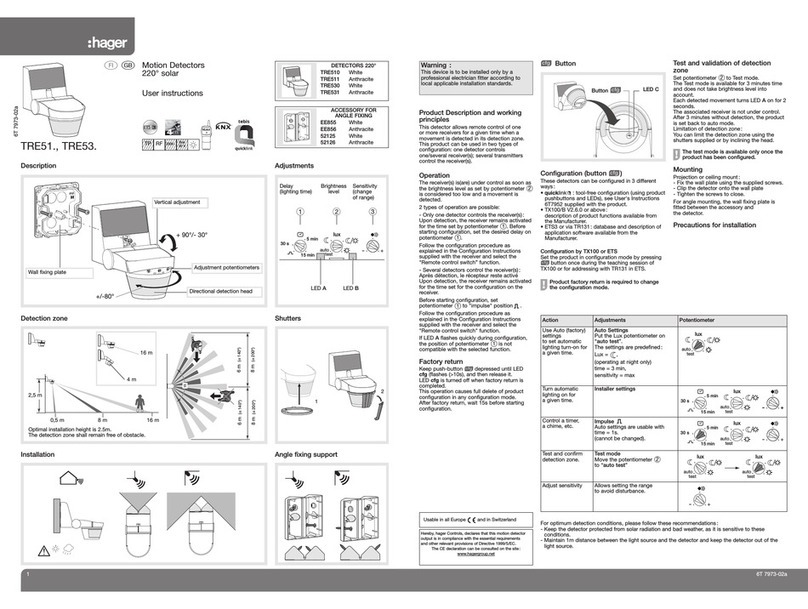

2. Installation

The detector comes ready powered. Simply lock it on to its base (step 4. Chapter 2.2. Installing the detector as a standalone device) to

put it in normal operating mode.

• The heat detector is not intended to replace smoke or gas detectors to ensure the safety of people and especially in rooms such as

bedrooms, playroom and other places of life.

• The heat detector is suitable for fire detection where an optical smoke detector can not be used.

• For minimum fire protection, a smoke detector should be installed at least in each corridor or stairwell and in each bedroom (refer to the

S155-22X smoke detector manual, for example).

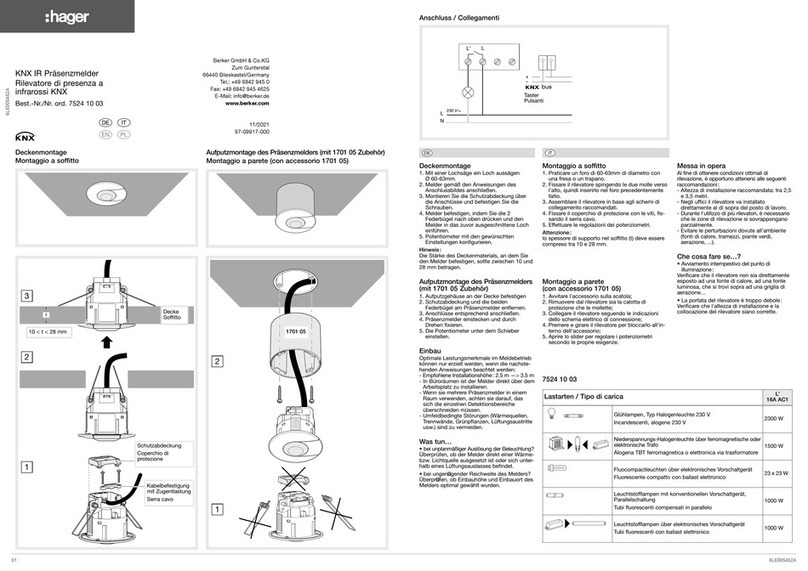

2.1. Choosing the best place to install the detector

The detector must be placed:

• in rooms where there is a fire hazard (living rooms with

fireplace, children’s bedrooms, occupied lofts or

basements, etc.) (Fig. A),

• preferably in the centre of the ceiling,

• far away from fan vents likely to spread smoke,

• more than 50 cm away from any obstacles (walls,

partitions, beams, etc.) (Fig. B),

• at each end of corridors if they are longer than 10 m.

If the detector cannot be installed horizontally on the ceiling,

fix it:

• at a distance of 40 to 50 cm from the ceiling (Fig. A),

• far away from any sources of electrical disturbance

(electricity meter, metal cabinet, electronic ballast, etc.).

The detector must not be placed:

• close to an electronic ballast, low voltage transformer,

energy saving light bulbs, fluorescent tubes, etc. (minimum

distance: 50 cm),

• in excessively dusty rooms,

• in a room where the temperature might drop below -10°C

or rise above +65°C, which would prevent the detector

from operating properly,

• at least 1 m away from heating, cooling or air circulation

vents likely to disseminate smoke or heat,

• at least 6 m away from a fireplace or wood burning stove

where the smoke from combustion might trigger an

unnecessary alarm,

• in a room where there might be condensation or damp (do

not use in bathrooms, laundries, etc.)

• at the centre of a pointed ceiling (A-shaped), as the air

pocket located here can prevent smoke from reaching the

detector (Fig. B),

• directly on to a metal wall: use a non-magnetic spacer

(wooden or plastic).

A

Recommended

location

d > 50 cm

50 cm > d > 40 cm

Accepta le

location

d > 50 cm

B

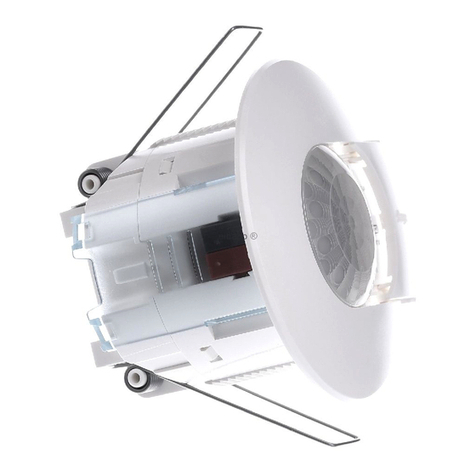

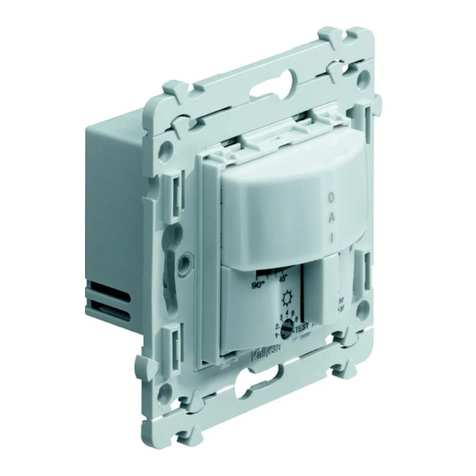

2.2. Installing the detector as a standalone device

Use the LED alignment arrow on the base in order to position the detector in the best possible manner (see Description).

Fix the base keeping in mind the precautions outlined

in the chapter entitled Choosing the best place to install

the detector. The detector can be fixed in 2 ways:

Fixing the detector on a flush-mounting box

• For Ø 60 mm boxes, use fixing holes marked 60.

• For Ø 78 mm boxes, use fixing holes marked 78.

• For Ø 85 mm boxes, use fixing holes marked 85.

• Fix the base using suitable screws.

Fixing the detector on a surface

• Place the base in the planned location and mark the

position of the 2 fixing holes with a pencil.

• Drill the holes using the right-sized diameter drill bit.

• Fix the base in place using suitable wall plugs and

screws.

1Optional locking of the detector on themounting base.

Optional locking is designed to prevent unauthorized

dismounting of the detector.

Using cutting pliers, cut out the locking slot.

2

Opening will now be possible only by

means of a flat blade screwdriver.