TNC 426/TNC 425/TNC 415 B/TNC 407

1 Introduction

1.1 The TNC 400 Series ............................................................................1-2

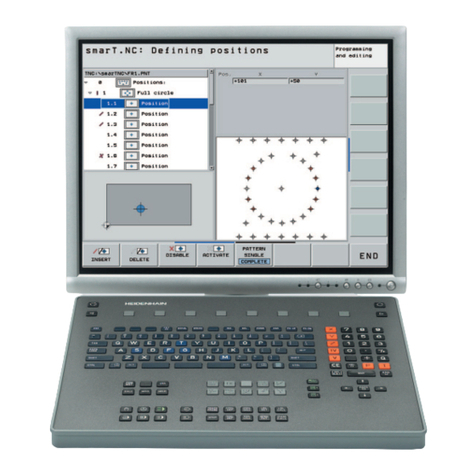

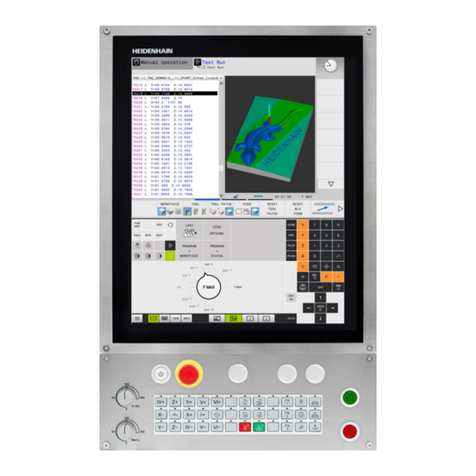

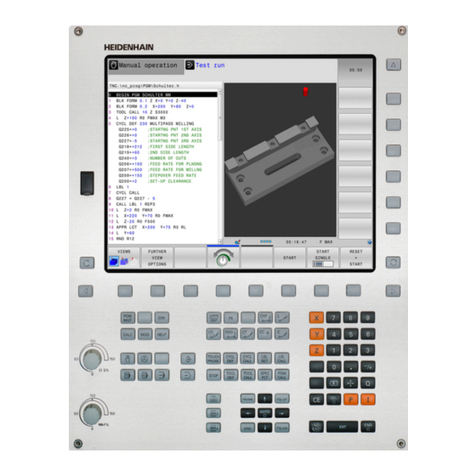

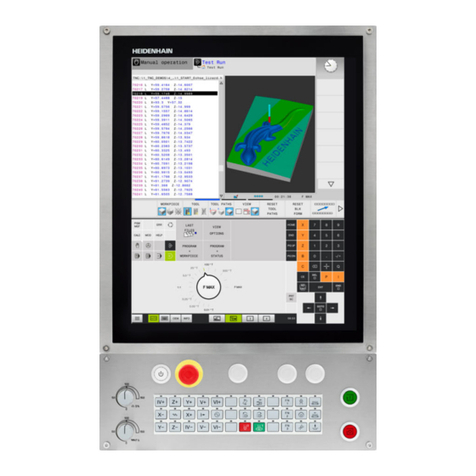

Keyboard........................................................................................................................ 1-4

Visual display unit .......................................................................................................... 1-5

TNC Accessories ........................................................................................................... 1-9

1.2 Fundamentals of NC.........................................................................1-10

Introduction .................................................................................................................. 1-10

What is NC? ................................................................................................................. 1-10

The part program .........................................................................................................1-10

Programming ............................................................................................................... 1-10

Reference system ........................................................................................................ 1-11

Cartesian coordinate system ....................................................................................... 1-11

Additional axes............................................................................................................. 1-12

Polar coordinates .........................................................................................................1-12

Setting the pole ............................................................................................................ 1-13

Datumsetting ............................................................................................................... 1-13

Absolute workpiece positions.......................................................................................1-15

Incremental workpiece positions ..................................................................................1-15

Programming tool movements ..................................................................................... 1-18

Position encoders ........................................................................................................ 1-18

Reference marks......................................................................................................... 1-18

1.3 Switch-On ..........................................................................................1-19

1.4 Graphics and Status Displays .........................................................1-20

Graphics during program run ....................................................................................... 1-20

Plan view...................................................................................................................... 1-21

Projection in 3 planes................................................................................................... 1-22

Cursor position during projection in 3 planes ............................................................... 1-23

3D view ........................................................................................................................ 1-23

Magnifying details ........................................................................................................ 1-25

Repeating graphic simulation....................................................................................... 1-26

Measuring the machining time ..................................................................................... 1-26

Status displays ............................................................................................................. 1-27

Additional status displays.............................................................................................1-27

1.5 File Management on the TNC 426 ...................................................1-30

Data security ................................................................................................................ 1-30

Calling the file manager ............................................................................................... 1-31

Functions for file management..................................................................................... 1-35

Selecting file types .......................................................................................................1-36

To copy individual files ................................................................................................. 1-36

To copy several files into another directory ................................................................. 1-37

To erase a file ..............................................................................................................1-38

To rename a file ........................................................................................................... 1-38

To protect a file ............................................................................................................ 1-38

To cancel file protection ...............................................................................................1-38

To convert a file ........................................................................................................... 1-39