Safety and Operating Instructions

• The absolute shaft encoders of the type RA 58-P/RA 59-P model series are

quality products manufactured in accordance with established electrical

engineering standards.

The units have been delivered from the factory in perfect conformance to

safety regulations.

To maintain this condition and to ensure trouble-free operation, please ob-

serve the technical specifications of this document.

• Installation and mounting may only be performed by an electrotechnical

expert!

• The units may only be operated within the limits specified by the technical

data.

•Maximum operating voltages must not be exceeded!

The units are designed complying with DIN EN 61010-part 1, protection class III.

To prevent dangerous structure-borne currents, the equipment has to be run

on safety extra-low voltage (SELV) and must be in an area of equipotential

bonding.

Please use an external fuse for protection (see Electrical Data).

• Fields of application: industrial processes and controls.

Overvoltage at the connecting terminals must be limited to overvoltage-

class-II values.

• Please avoid shocks to the housing – especially to the encoder shaft – and

axial or radial overload to the encoder shaft.

• Maximum accuracy and durability of our shaft encoders are only granted

when using suitable couplings.

• The high-quality EMC-specifications are only valid together with standard-

type cables and plugs. When using screened cables, the screen must broadly

be connected with ground on both ends. Likewise, the voltage-supply cables

should entirely be screened. If this is not possible you will have to take

appropriate filtering measures.

• Installation environment and wiring are influential on the encoder's EMC:

Thus the installer must secure EMC of the whole facility (device).

• In electrostaticly threatened areas please take care for neat ESD-protection

of plug and connecting cable during installation work.

• Specified maximum shaft loads are only given under restrictions:

– Full bearing life of 1 x 1010 revolutions (typ.) will be reached at 35% of

full rated shaft load

– a bearing life of 1 x 108revolutions (typ.) will be reached at 100% of full

rated shaft load.

Installation instructions

Absolute Shaft Encoders RA 58-P/RA 59-P,

Interbus (K3)

Item No. 2 543 043 Edition: 25.02.99

Hengstler GmbH

Postfach 11 51 Tel. 07424 – 890

D-78550 Aldingen Fax 07424 – 89370

Introduction

These installation instructions are provided for the connection and starting

procedure of your shaft encoder.

For further informations see user guide:

•RA 58-P/RA 59-P with Interbus (K3): Item No. 2 543 003

General aspects

The shaft encoder of the type RA 58-P/RA 59-P can be programmed via the

Interbus. Due to this function the encoder may be used universally; thus the

range of variants as well as the storage will be reduced for the customer.

A lot of calculating time and expense on the host system will be saved by

data processing within the encoder.

The RA 58-P/RA 59-P is equipped with an EEPROM for remanent storage of

the parameters. When the device is turned on the parameters are transferred

automatically to the memory.

This sign marks paragraphs particularly to be observed to assure

proper use and to avoid risks.

Mechanical data

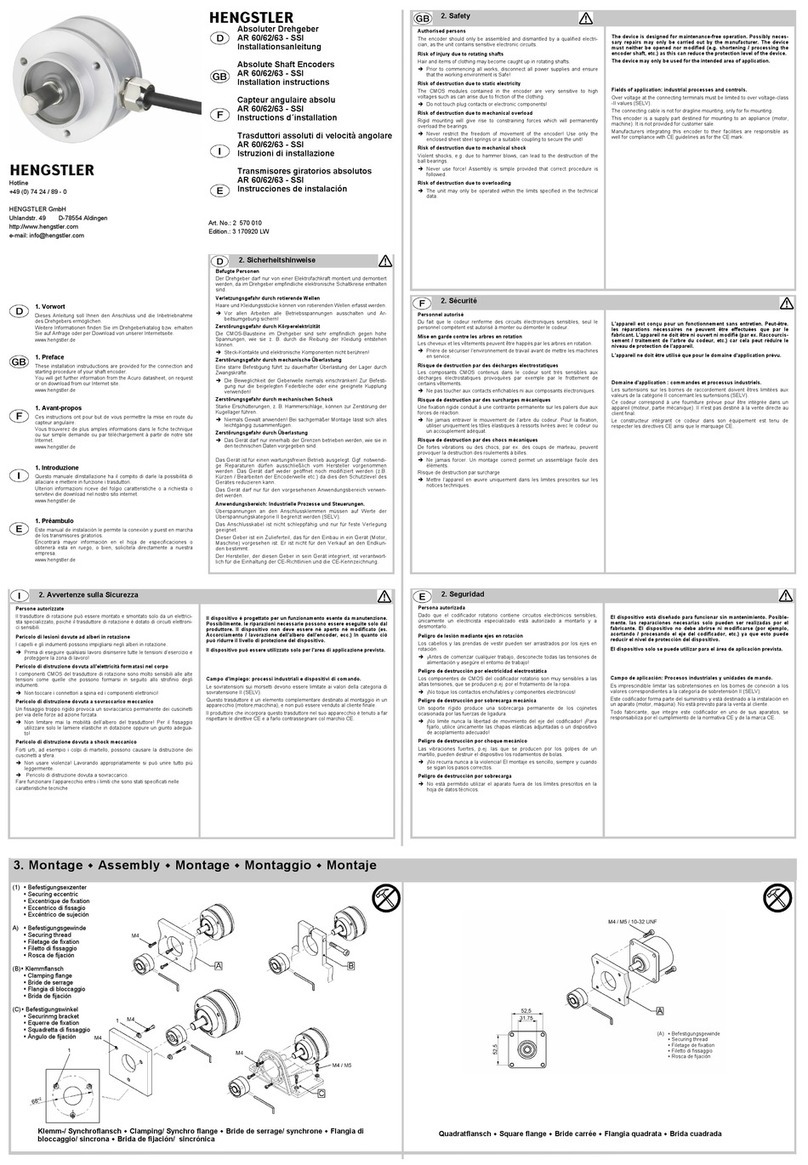

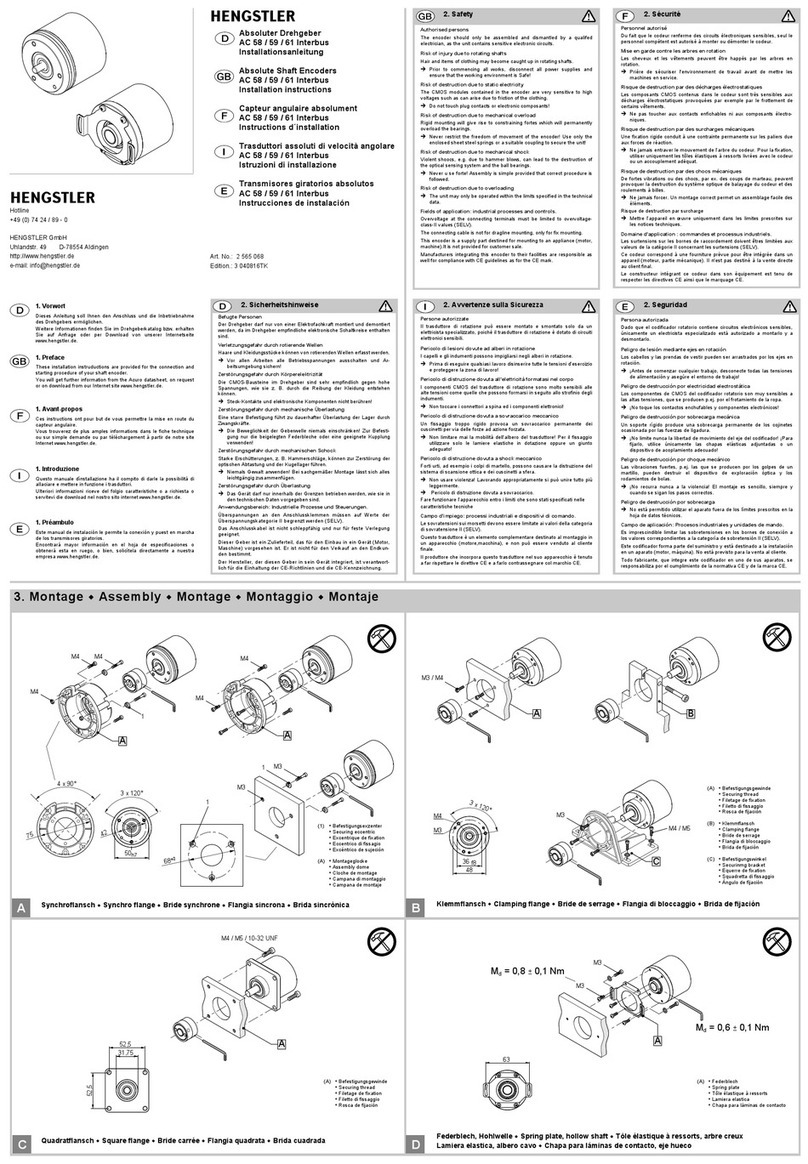

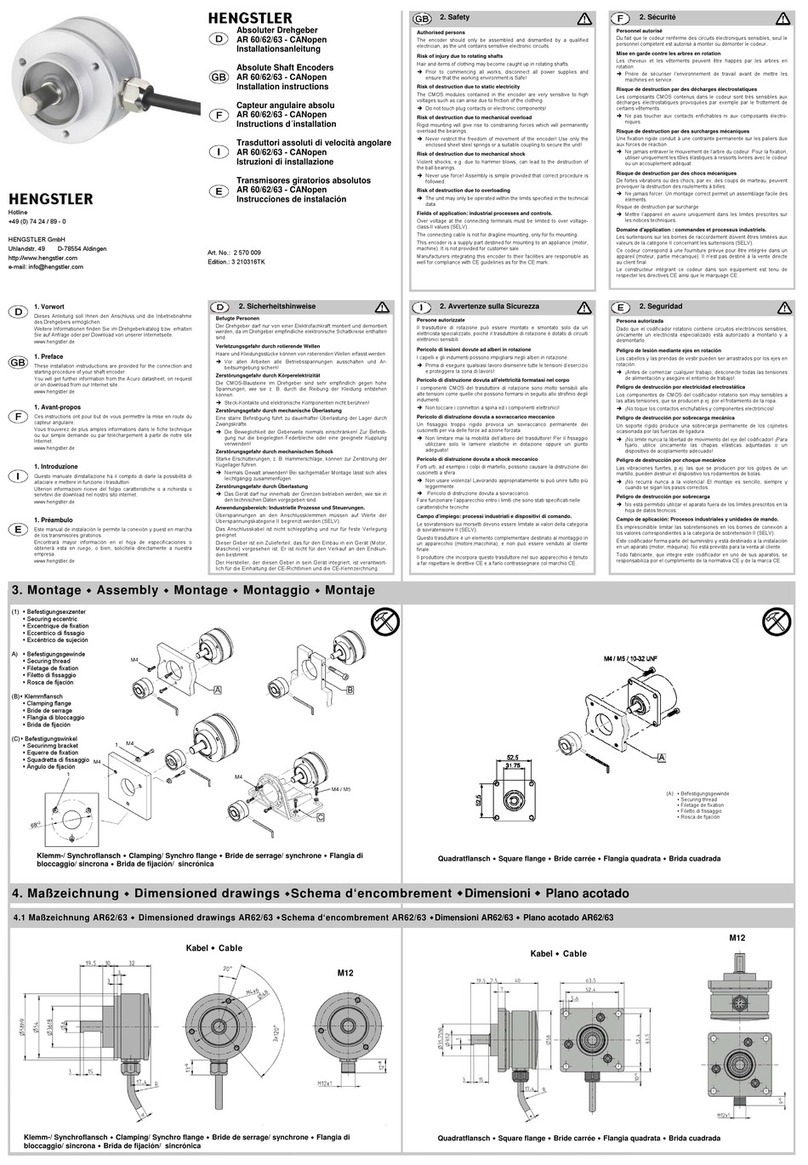

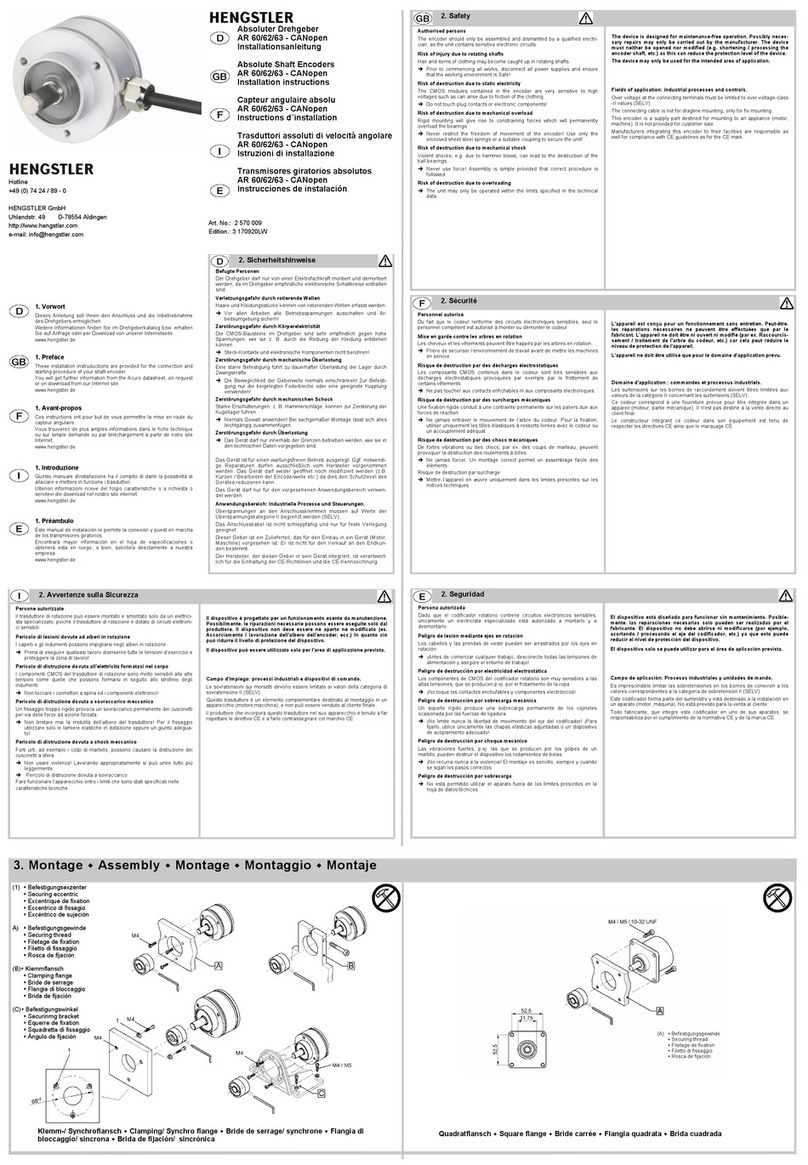

Shaft diameter 6 mm (synchro flange) / 10 mm (clamping flange)

Max. shaft load ∅6 mm: axial 60 N (13 lbs), radial 110 N (24 lbs)

∅ 10 mm: axial 107 N (24 lbs), radial 160 N (35 lbs)

Speed 10000 RPM (short term), 6000 RPM (continuous duty)

Torque ≤ 0.5 Ncm

Moment of inertia synchro flange approx. 14 gcm2,

clamping flange approx. 20 gcm2

Protection class (EN 60529) housing IP 65*, bearing IP64*

Operating temperature –10 … +60 °C

Storage temperature –25 … +85 °C

Vibration performance (IEC 68-2-6) 100 m/s2(10 … 500 Hz)

Shock resistance (IEC 68-2-27) 1000 m/s2(6 ms)

Types of connection cable axial/radial, connector axial/radial,

connector 2-fold radial, bus terminal box

Housing aluminium

Flange S = synchro flange**, K = clamping flange***

Weight 350 g approx.

Bearing life 1 x 1010 revolutions (typ.) at 35 % of full rated shaft load

1 x 109revolutions (typ.) at 75 % of full rated shaft load

1 x 108revolutions (typ.) at 100 % of full rated shaft load

* IP 67 for singleturn versions on request

** Mounting with screws M4 *** Mounting with screws M3 or M4

General design as per EN 61010-part 1, protection class III,

contamination level 2, overvoltage class II

Supply voltage1) 10 ... 30 VDC (SELV) with pole protection

Power consumption max. 0.2 A

Recommended external fuse T 0.25 A

Max. current for througoing max. 4.5 A (connector 2-fold),

voltage supply; max. 2 A (bus terminal box);

recommended external fuse T 4.5 A (connector 2-fold), T 2 A (bus terminal box)

EMC Noise emission as per EN 50081-2,

noise immunity as per EN 50082-2

Linearity ± ½ LSB

Type of code Binary

Interface RS 485 for installation remote bus

Protocol Interbus with ENCOM profile K3 (can be parameterised)

Signal lines 5 V difference signals, with potential-free

power supply

Baud rate 500 KB

Update every 600 µs

Physical resolution2) 1024 increments (10 Bit)

4096 increments (12 Bit)

1024 increments/4096 revolutions (22 Bit)

4096 increments/4096 revolutions (24 Bit)

Programmable functions Code sequence, scaling factor, preset, offset

Max. cable length 50 m

1) Real code-disc resolution; in addition, the desired resolution can be reduced by programming

of the encoder parameters

2) Power unit within encoder: potential-free DC/DC converter, 500 V AC withstand voltage between

mains input and electronics

Electrical data

Function (programming directly Preset values Customer-specific

by bus, using configuration- (manufacturer’s parameters

parameter transfer) standard settings)

Code sequence for clockwise rotation ascending

Offset (CP-No. 05) 0

Preset value (CP-No. 04) 0

Scaling factor (CP-No. 08) 1*

* maximal resolution

Programmable functions

Item No. 2 543 043, Edition: 25.02.99

Subject to technical modifications and improvements serving the progress of our devices.