Contents

ii

5.1.11 SP-11 Clean-Out Time..................................................................................25

5.1.12 SP-12 Clean-Out Temperature ......................................................................25

5.1.13 SP-13 Cooking User IO ................................................................................25

5.1.14 SP-14 Number Of Baskets............................................................................25

5.1.15 SP-15 Cooking Indicator...............................................................................25

5.1.16 SP-16 2nd Language ...................................................................................25

5.1.17 SP-17 2nd Volume .......................................................................................25

5.1.18 SP-18 Energy Save Mode.............................................................................26

5.1.19 SP-19 Fryer Type.........................................................................................26

5.1.20 SP-20 Vat Type............................................................................................26

5.1.21 SP-21 Auto-Lift Enabled ...............................................................................26

5.1.22 SP-22 Bulk Oil Supply ..................................................................................26

5.1.23 SP-23 Bulk Oil Disposal................................................................................26

5.1.24 SP-24 Serial Number Log .............................................................................27

5.1.25 SP-25 Program Code Change.......................................................................27

5.1.26 SP-26 Usage Code Change..........................................................................27

5.1.27 SP-27 Dispose Requires Code?....................................................................27

5.1.28 SP-28 Longer Fill Time .................................................................................28

5.1.29 SP-29 Let User Exit Fill.................................................................................28

5.1.30 SP-30 Skip Skim Prompt ..............................................................................28

5.1.31 SP-31 Skip Exp Filter Confirm .......................................................................28

5.1.32 SP-32 2–Stage Wash Enabled ......................................................................28

5.1.33 SP-33 Daily Filter Lockout Enabled................................................................28

5.1.34 SP-34 Daily Filter Period Start Time...............................................................28

5.1.35 SP-35 Daily Filter Reminder Time..................................................................28

5.1.36 SP-36 Quick Configuration Menu ..................................................................28

5.2 Do Not Disturb .....................................................................................................29

5.3 Clock Set.............................................................................................................29

5.4 Data Logging, Heat Control, Tech, Stat, & Filter Control Modes................................30

5.5 Tech Mode...........................................................................................................30

5.5.1 T-1 Software..................................................................................................31

5.5.2 T-2 Fryer Type ...............................................................................................31

5.5.3 T-3 Push-Button Test......................................................................................31

5.5.4 T-4 All On Display Test ...................................................................................31

5.5.5 T-5 Segments Test .........................................................................................31

5.5.6 T-6 Digits Test................................................................................................31

5.5.7 T-7 Decimal Points Test..................................................................................32

5.5.8 T-8 LED’s Test ...............................................................................................32

5.5.9 T-17 Inputs - HDF ..........................................................................................32

5.5.10 T-18 AIF Info (AIF PCB Communicating With Control PCB?) ...........................32

5.5.11 T-19 Outputs................................................................................................32

5.5.12 T-20 - AIF INFO ...........................................................................................33

5.5.13 T-21 Pumps & Valves ...................................................................................34

5.6 Stats Mode ..........................................................................................................35

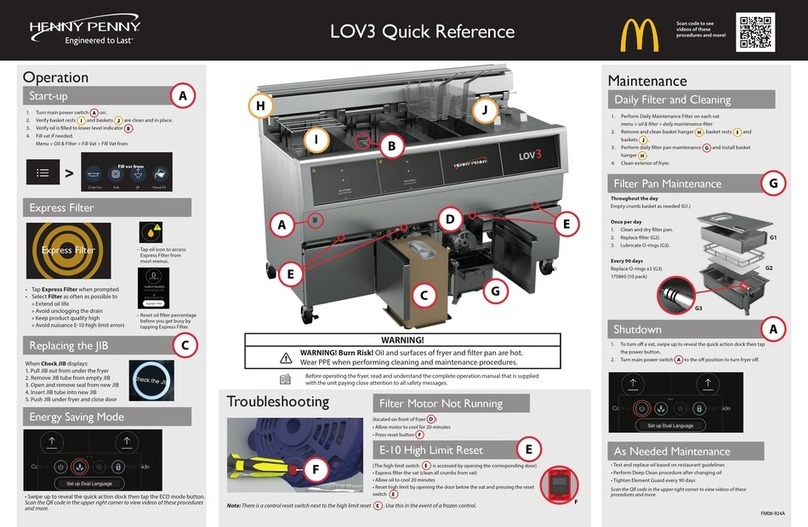

Chapter 6 Maintenance .................................................................................................37

6.1 Introduction .........................................................................................................37

6.2 Maintenance Hints ...............................................................................................37

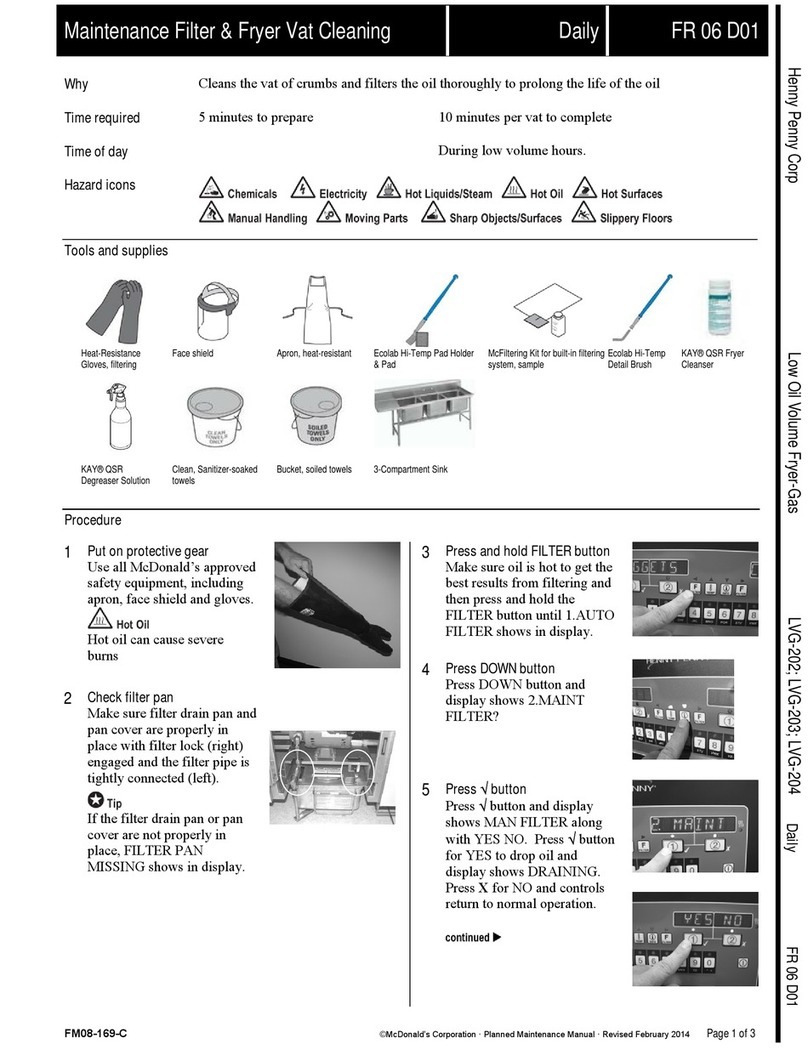

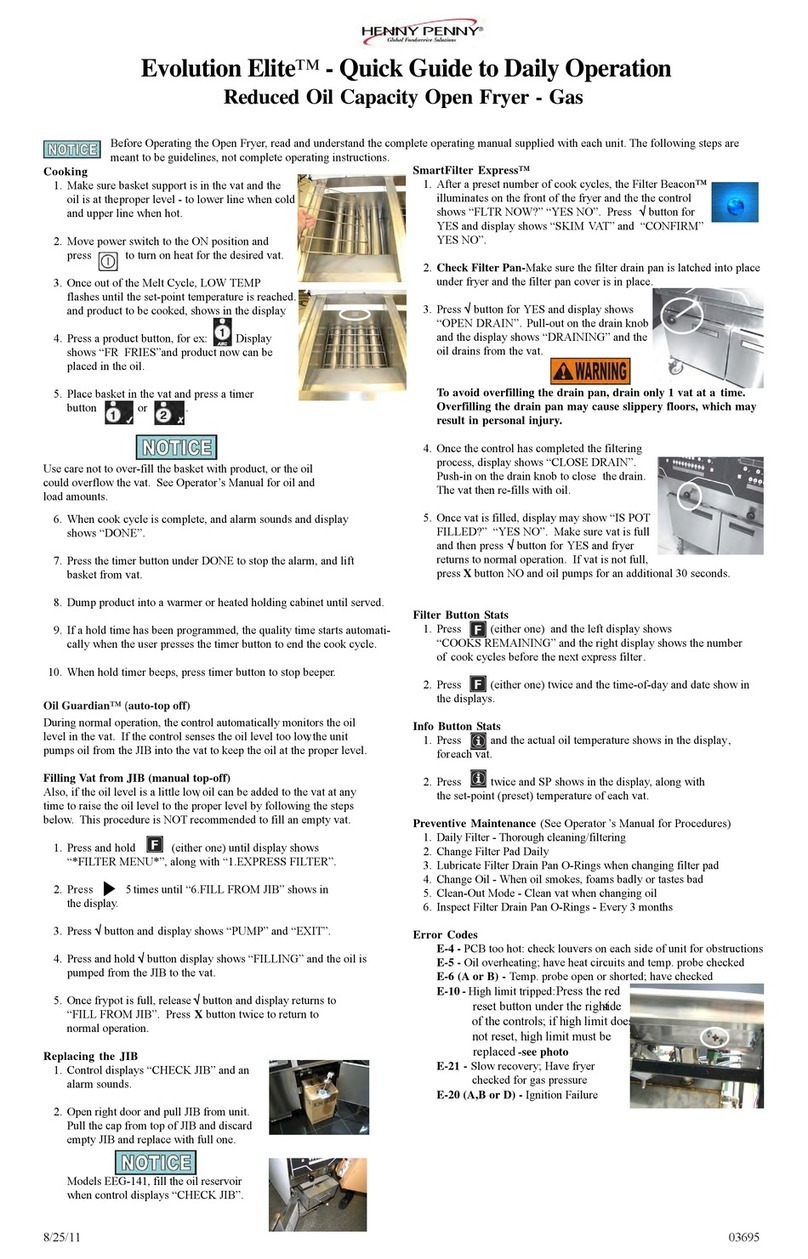

6.3 Preventative Maintenance ....................................................................................37

6.4 Control Panel & Menu Card Replacement ..............................................................38

6.5 High Temperature Limit Control ............................................................................. 39

6.6 Main Power Switch...............................................................................................40

6.7 Temperature Probe ..............................................................................................41