Introduction

Thank you for purchasing the HIOKI “3454-11 DIGITAL MΩHiTESTER”. To

obtain maximum performance from the instrument, please read this manual

first, and keep it handy for future reference.

Initial Inspection

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Preliminary Checks

• Before using the instrument the first time, verify that it operates normally to

ensure that the no damage occurred during storage or shipping. If you find

any damage, contact your dealer or Hioki representative.

• Before using the instrument, make sure that the insulation on the test leads

and connection cords is undamaged and confirm that the white or red portion

(insulation layer) inside the cable is not exposed. If a color inside the cable is

exposed, do not use the cable. Using the product in such conditions could

cause an electric shock, so contact your dealer or Hioki representative for

replacements (Model L9787).

Maintenance and Service

• To clean the instrument, wipe it gently with a soft cloth moistened with water or

mild detergent. Never use solvents such as benzene, alcohol, acetone, ether,

ketones, thinners or gasoline, as they can deform and discolor the case.

• If the instrument seems to be malfunctioning, confirm that the batteries are

not discharged, and that the test leads and fuse are not open circuited before

contacting your dealer or Hioki representative.

• When an indication Err.9 appears, send the instrument for repair.

General Specifications

rdg. :reading value (The value currently being measured and indicated on the

measuring instrument)

dgt. :resolution (The smallest displayable unit, i.e., the input value that causes

the digital display to show a "1".)

Insulation Resistance Measurement

* Resistances of 1000 MΩor higher are indicated in increments of 10 MΩi.e.,

1010 MΩ, 1020 MΩ, etc.

Operation uncertainty B: ±18% (1st effective measurement range)

Measurement terminal voltage characteristic.

Effect of radiated radio-frequency electromagnetic field: 3 V/m, within +10%rdg.

Resistance Measurement

Short circuit current: 200 mA or more, open circuit voltage: 5 VDC±1 V

Operation uncertainty B: ±30% (0.2 to 400 Ω)

AC Voltage Measurement

Input resistance: 100 kΩor more, Frequency range: 50 to 60 Hz

Measurement Categories

This instrument complies with CAT III safety requirements. To ensure safe

operation of measurement instruments, IEC 61010 establishes safety stan-

dards for various electrical environments, categorized as CAT

II

to CAT IV, and

called measurement categories.

CAT II: Primary electrical circuits in

equipment connected to an AC electri-

cal outlet by a power cord (portable

tools, household appliances, etc.)

CAT II covers directly measuring electri-

cal outlet receptacles.

CAT III: Primary electrical circuits of

heavy equipment (fixed installations)

connected directly to the distribution

panel, and feeders from the distribution

panel to outlets.

CAT IV:The circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel).

Using a measurement instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV

measurement applications could result in a severe accident, and must be care-

fully avoided.

Safety Symbol

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before using it,

be sure to carefully read the following safety precautions.

The following symbols in this manual indicate the relative importance of cau-

tions and warnings.

Indicates that incorrect operation presents an extreme hazard that could

result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could

result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or

damage to the instrument

Indicates advisory items related to performance or correct operation of the

instrument.

Follow these precautions to ensure safe operation and to obtain the full bene-

fits of the various functions.

• To avoid battery depletion, turn the function selector OFF after use (the Auto

Power Save feature consumes a small amount of current).

• The safety sleeve is attached to the test lead plug.Remove the sleeve before

connecting to the instrument.

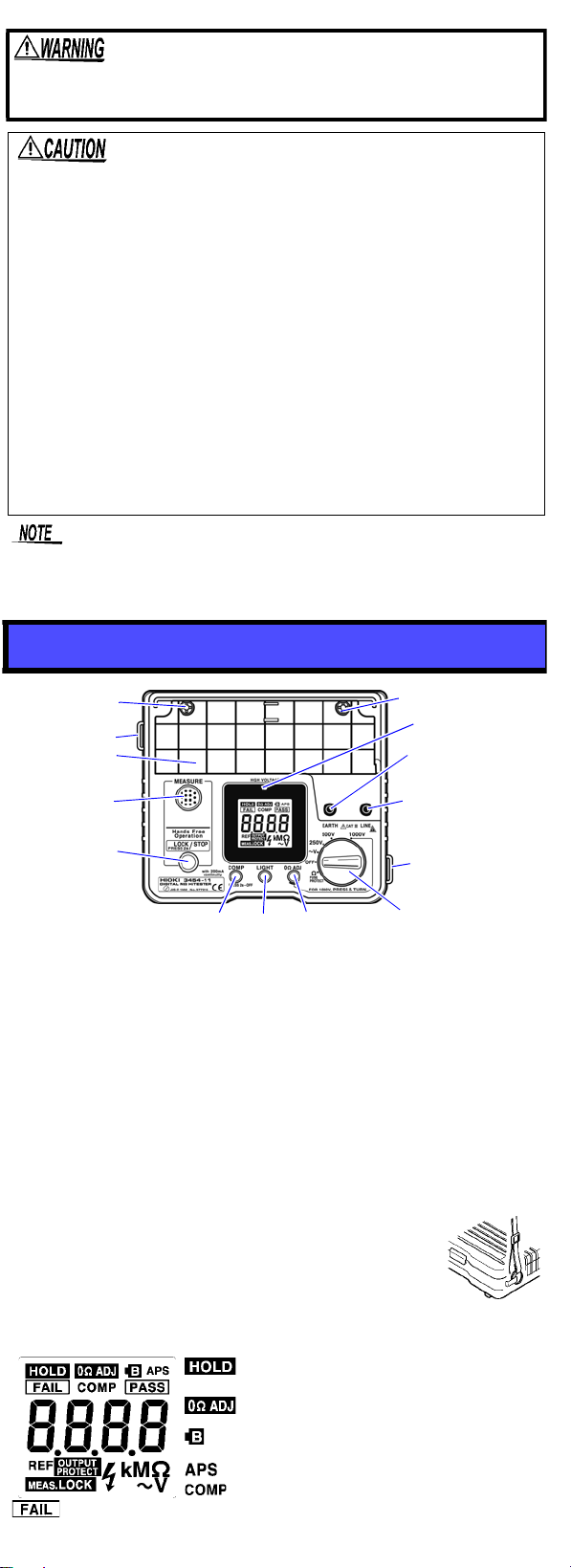

1. Function Selector: Selects among power ON/OFF, the output voltage for

insulation resistance measurement, ACV, or resistance (Ω).

2. MEASURE Key: Used to measure resistance and insulation resistance.

This key remains ON while it is held down.

3. LOCK Key: Used to measure resistance and insulation resistance. This key

switches ON if held down for more than 2 seconds. Press the key again to

turn it OFF.

4. COMP Key: Used for the comparator function

5. LIGHT Key: Turns the display light ON/OFF. The light automatically

switches OFF after 30 seconds.

6. 0ΩADJ Key: Used for the zero-adjust function in resistance measurement

Used when "1000 V" is selected in insulation-resistance measurement

Used to select the buzzer sound in the comparator function

7. High-voltage warning lamp: Begins flashing if the input voltage exceeds AC

70 V (±10 V) and during insulation resistance measurement.

8. EARTH Measurement Terminal: Connect the black test lead to this terminal.

9. LINE Measurement Terminal: Connect the red test lead to

this terminal.

10.Strap Hole: Pass the strap through this hole.

11.Test lead Housing: Houses the test leads. The test leads may be

housed without disconnecting them from the terminals after use.

12.Sleeve stand: Attach the sleeve removed from the tip of the

test lead.

Display Block

: Lights up when the measured value is less than the criterion for the comparator

function during insulation-resistance measurement, or when the measured value

is greater than the criterion during resistance measurement.

Specifications

Guaranteed accuracy

period 1 year at

23°C

±

5°C (73°F

±

9°F) and 90% RH

Display Max. 4000 LCD

Sampling rate twice/second

Response time Insulation resistance (∞0, ∞center value),

resistance: Within 5 s, ACV: Within 2 s

Operating Temperature

&Humidity 0 to 40

°C (32 - 104°F)

, 90%RH or lower

(non-condensating)

Storage Temperature

&Humidity -20 to 50

°C (-4 - 122°F)

, 90%RH or lower

(non-condensating)

Operating Environment Indoors, altitude up to 2000 m (6562-ft.) ASL,

Pollution Degree 2

Effect of temperature

0 to 18

°C

, 28 to 40

°C

(32 to 64

°F

, 82 to

104

°F

)

±2% of reading ±5 dgt,

plus basic allowance

(Resistance Measurement 4 MΩ range: ±5% of reading

plus basic allowance)

Influence quantity

E1 (Position) : 0%

E2 (Supply voltage) : Twice of the intrinsic uncertainty

E3 (Temperature) : ±2%±5d

gt.

(Influencing factor non-applicable for E4to E10)

Degree of protection IP40 (condition which the test lead is connected)

Power source Rated power voltage: 1.5 V DC × 4,

R6P manganese battery × 4 or LR6 alkaline battery × 4

Maximum rated power 3 VA

3454-11

DIGITAL MΩHiTESTER

Instruction Manua

January 2012 Revised edition 13

Printed in Japan

3454A981-13 12-01H

Continuous operating

time Insulation ∞measurement at 250 V and 500 V for

about 10 hours, at 1000 V for about 10 hours (with

manganese battery)

Possible number of

measurements

250 V at 0.25 MΩ300 times (R6P battery), 1600 times

(LR6 battery)

500 V at 0.5 MΩ250 times (R6P battery), 1400 times

(LR6 battery)

1000 V at 1.0 MΩ200 times (R6P battery), 1000 times

(LR6 battery)

Ωat 1.0 Ω1000 times (R6P battery), 1000 times (LR6

battery)

Additional function Automatic power-saving mode, Comparator, High-volt-

age warning, Warning indication of false voltage input,

Data hold, Display lighting, 1000 V output error protec-

tion, Zero adjustment

Dielectric strength 5550 V AC 50/60 Hz for one minute

Between electric circuit and case

Maximum input voltage

Maximum rated voltage

to earth 600 V AC,

Measurement Category III

(Anticipated Transient Overvoltage: 6000 V)

Input error protection

for 10 second

(overvoltage protection)

600 V AC

(ACV function: 800 V AC)

(MΩ-1000 V function: 1200 V AC)

Dimensions

(excluding protrusions) 175W × 148H × 56D mm approx.

6.89"W × 5.83"H × 2.20"D approx.

Mass 530 g, 18.7 oz. approx. (including batteries)

Accessories L9787 Test Lead, Instruction Manual,

R6P manganese battery × 4, Strap

Options

L9787-91 Breaker Pin, 9804-02 Magnetic Adapter,

L9787 Test Lead

Standards applying Safety EN61010

EMC EN61326

EN 61557-1/-2/-4

Rated output voltage (DC) Max. effective reading Center scale reading

250 V / 500 V 500 MΩ10 MΩ

1000 V 4000 MΩ100 MΩ

Rated output voltage Display range Max. reading Resolution

250 V / 500 V / 1000 V 4 MΩrange 4.000 MΩ0.001 MΩ

40 MΩrange 40.00 MΩ0.01 MΩ

400 MΩrange 400.0 MΩ0.1 MΩ

250 V / 500 V 500 MΩrange 500 MΩ1 MΩ

1000 V 4000 MΩrange 4000 MΩ1 MΩ*

Rated output

voltage Name of measurement

range Measurement range Accuracy & Intrinsic

uncertainty A

250 V / 500 V

1st effective

measurement range

0.200 to 50.0 MΩ±3%rdg. ±4dgt.

2nd effective

measurement range

50.1 to 500 MΩ±5%rdg. ±5dgt.

other measurement range

0 to 0.199 MΩ

1000 V

1st effective

measurement range

0.200 to 200.0 MΩ±3%rdg. ±4dgt.

2nd effective

measurement range

200.1 to 4000 MΩ±5%rdg. ±5dgt.

other measurement range

0 to 0.199 MΩ

Rated

output

voltage Open circuit

voltage Lower limit measurement

resistance value to be maintained

rated output voltage Rated

current Short circuit

current

250 V 1 to 1.2

times of

nominal

testvoltage

0.25 MΩ

1 to 1.2 mA 1.2 mA

max.

500 V 0.5 MΩ

1000 V 1 MΩ

Display range Max. reading Resolution Accuracy & Intrinsic

uncertainty A

(After 0 Ω Adjustment)

40 Ωrange 40.00 Ω0.01 Ω

±3%rdg. ±6dgt.

400 Ωrange 400.0 Ω0.1 Ω

4 kΩrange 4.000 kΩ0.001 kΩ

40 kΩrange 40.00 kΩ0.01 kΩ

400 kΩrange 400.0 kΩ0.1 kΩ±5%rdg. ±6dgt.

4 MΩrange 4.000 MΩ0.001 MΩ

Display range Max. reading Resolution Accuracy

(

Guaranteed at 600 V or less)

600 V range 750 V 1 V ±3%rdg. ±6dgt.

Safety

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as damage

to the instrument. Using the instrument in a way not described in this

manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or inju-

ries not resulting directly from instrument defects.

In the manual, the symbol indicates particularly important

information that the user should read before using the instrument.

The symbol printed on the instrument indicates that the user

should refer to a corresponding topic in the manual (marked with

the symbol) before using the relevant function.

Indicates that dangerous voltage may be present at this terminal.

Indicates a double-insulated device.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Usage Notes

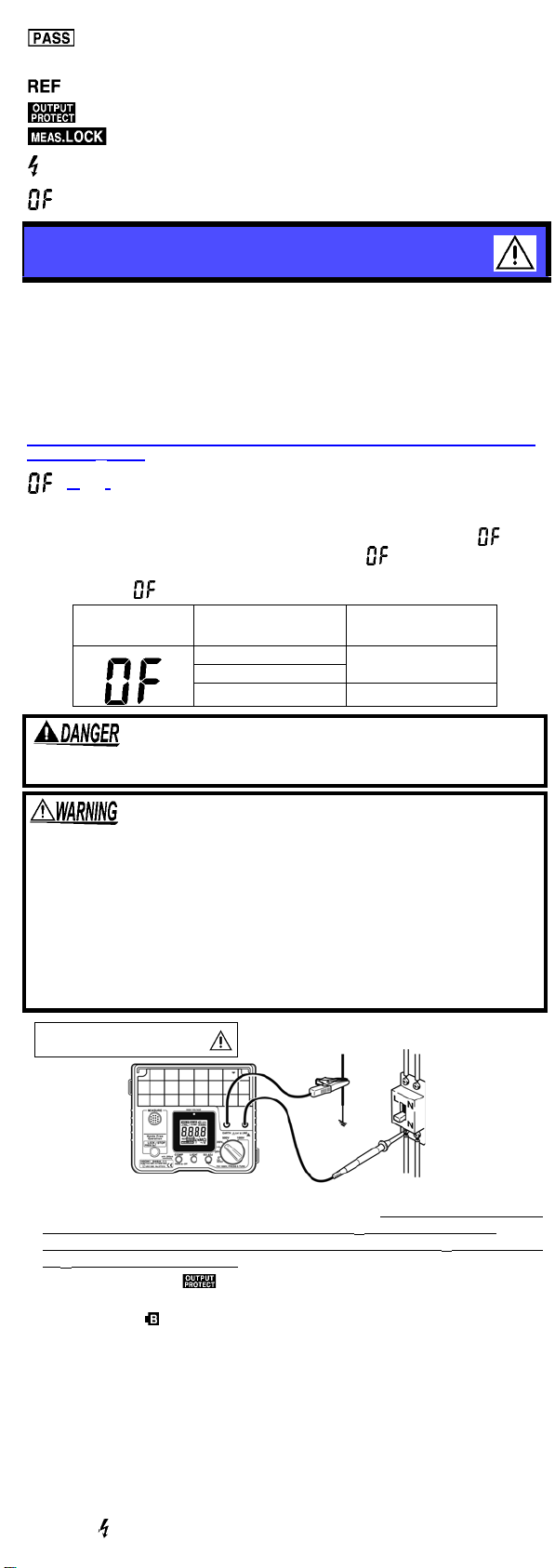

Observe the following precautions to avoid electric shock.

• Be sure to disconnect the test lead from the object to be measured

and turn the function switch OFF before connecting or disconnecting

the test lead from the MΩHiTESTER.

• Always verify the appropriate setting of the function selector before

connecting the test leads.

Disconnect the test leads from the measurement object before

switching the function selector.

• Do not use the instrument where it may be exposed to corrosive or com-

bustible gases. The instrument may be damaged or cause an explosion.

• Do not allow the instrument to get wet, and do not take measurements

with wet hands. This may cause an electric shock.

• Do not use any other electrical source other than the batteries. The

use of any other sources may result in damage of the instrument or

the object to be measured and also may cause electric shock.

• Before using the instrument, make sure that the insulation on the test

leads and confirm that the white or red portion (insulation layer) inside

the cable is not exposed. If a color inside the cable is exposed, do not

use the cable. Using the product in such conditions could cause an

electric shock, so contact your dealer or Hioki representative for

replacements (Model L9787).

• Do not use the instrument where it may be exposed to oil, chemicals, or

solvents. Contact with these substances may cause cracking in the

instrument, resulting in damage or electric shock.

• If the protective functions of the instrument are damaged, either remove it

from service or mark it clearly so that others do not use it inadvertently.

• This instrument is designed for use indoors. It can be operated at temper-

atures between 0 and 40°C without degrading safety.

• Do not store or use the instrument where it could be exposed to direct sun-

light, high temperature or humidity, or condensation. Under such condi-

tions, the instrument may be damaged and insulation may deteriorate so

that it no longer meets specifications.

• For safety reasons, when taking measurements, only use the L9787 Test

Lead (or optional) provided with the instrument.

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

• Calibration and repair of this instrument should be performed only under

the supervision of qualified technicians knowledgeable about the dangers

involved.

• Removable sleeves are attached to the metal pins at the ends of the test

leads. To prevent a short circuit accident, be sure to use the test leads with

the sleeves attached when performing measurements in the CAT III mea-

surement category. Remove the sleeves from the test leads when perform-

ing measurements in the CAT I and CAT II measurement categories. For

details on measurement categories, see "Measurement categories" in the

instruction manual.

Names and Functions of Parts

3.

2.

11.

10.

4. 5. 6. 1.

10.

9.

8.

7.

12.

12.

: Lights up when the measured value is held during

the resistance/insulation-resistance measurement.

: Lights up when 0Ωadjustment is made during

resistance measurement.

: Indicates that battery power is low. (during which

time accuracy cannot be guaranteed).

: Lights up when auto power save is enabled.

: Lights up when the comparator function is enabled.