Copyright HK Instruments 2021 www.hkinstruments. Installaon version 1.0 2021

Thesellerisobligatedtoprovideawarrantyofveyearsforthedeliv-

eredgoodsregardingmaterialandmanufacturing.Thewarrantyperiod

isconsidered tostart on thedelivery dateof theproduct.If a defect

in raw materials or a produconawisfound, theseller is obligated,

whentheproductissenttothesellerwithoutdelayorbeforeexpira-

onofthewarranty,toamendthemistakeathis/herdiscreoneither

by repairing the defecve product or by delivering free of charge to

thebuyeranewawlessproductandsendingittothebuyer.Delivery

costsfor therepairunderwarrantywillbepaidbythebuyer and the

return costs by the seller. The warranty does not comprise damages

causedbyaccident,lightning,oodorothernaturalphenomenon,nor-

malwearandtear,improperorcarelesshandling,abnormaluse,over-

loading,improperstorage,incorrectcareorreconstrucon,orchanges

andinstallaonworknotdonebytheseller.Theseleconofmaterials

fordevicespronetocorrosionisthebuyer’sresponsibility,unlessother-

wiseislegallyagreedupon.Shouldthemanufactureralterthestructure

ofthedevice, thesellerisnotobligatedtomakecomparablechanges

todevicesalreadypurchased.Appealingforwarrantyrequiresthatthe

buyerhascorrectlyfullledhis/herduesarisenfromthedeliveryand

stated in the contract. The seller will give a new warranty for goods

thathavebeenreplacedorrepairedwithinthewarranty,howeveronly

totheexpiraonoftheoriginalproduct’swarrantyme.Thewarranty

includestherepairofadefecvepartordevice,orifneeded,anewpart

ordevice,butnotinstallaonorexchangecosts.Undernocircumstance

isthesellerliablefordamagescompensaonforindirectdamage.

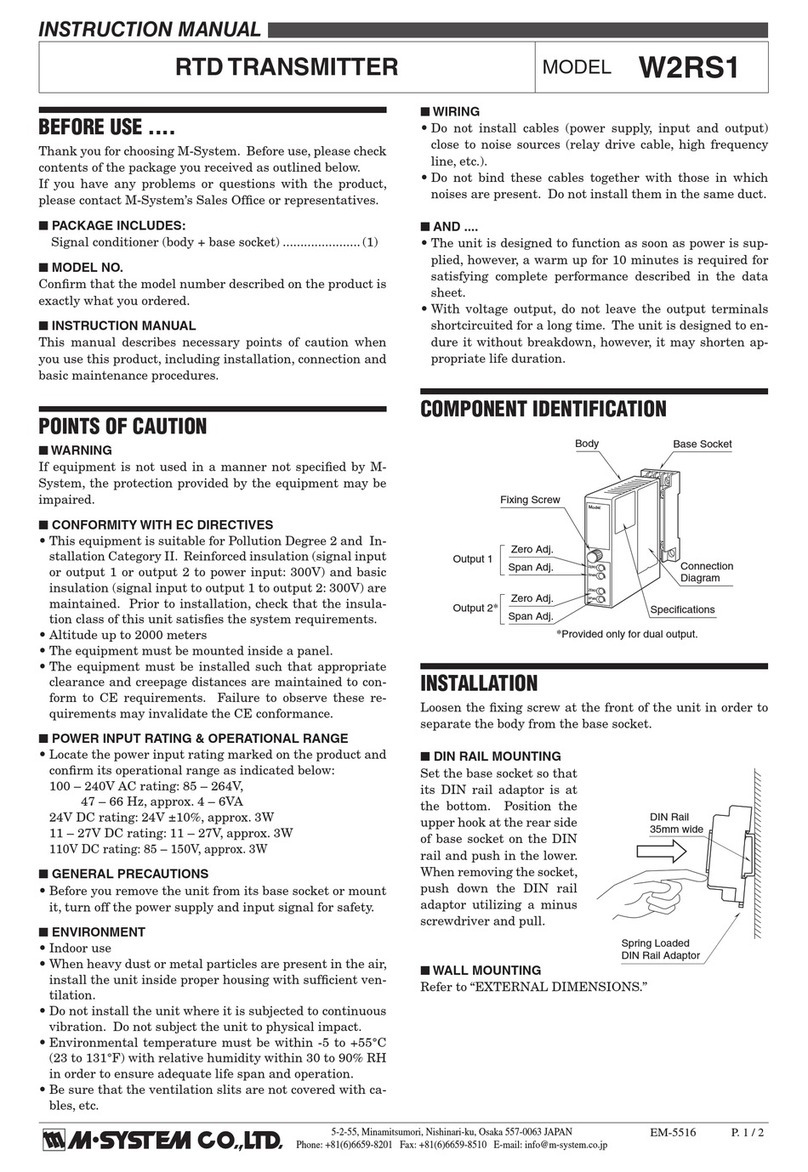

2)ManualPushbuonzeropointcalibraon

NOTE:Supplyvoltagemustbeconnectedatleastonehourpriortozero

pointadjustment.

a)Disconnectbothpressuretubesfromthepressureportslabeled+

and–.

b)PushdownthezerobuonunltheLEDlight(red)turnsonandthe

displayreads“zeroing”(displayopononly).(seeFigure4)

c)Thezeroingofthedevicewillproceedautomacallyin4seconds.

Zeroingledlightsonlyforamoment.Zeroiningiscompletewhen

thedisplayreads0(displayopononly).

d)ReinstallthepressuretubesensuringthattheHighpressuretube

isconnectedtotheportlabeled+,andtheLowpressuretubeis

connectedtotheportlabeled−.

STEP 8: ZEROING THE DEVICE

WARRANTY POLICY

RECYCLING/DISPOSAL

The parts le over from installaon should be

recycled according to your local instrucons.

Decommissioned devices should be taken to a

recyclingsitethatspecializesinelectronicwaste.

ZEROING THE DEVICE CONTINUED

1)Autozerocalibraon

Autozero calibraon (-AZ) is an autozero funcon in the form of an

automaczeroingcircuitbuiltintothePCBboard.Theautozerocali-

braon electronically adjusts the transmier zero at predetermined

me intervals(every10minutes).Thefuncon eliminatesalloutput

signaldriduetothermal,electronicormechanicaleects,aswellas

theneedfortechnicianstoremovehighandlowpressuretubeswhen

performing inial or periodic transmier zero point calibraon. The

autozeroadjustmenttakes4secondsaerwhichthedevicereturnsto

itsnormalmeasuringmode.Duringthe4secondadjustmentperiod,

theoutputanddisplayvalueswillfreezetothelatestmeasuredvalue.

Transmiersequippedwiththeautozerocalibraonarevirtuallymain-

tenancefreeandmanualzeroingisnotrequired.

Theresponsemeaectshowfastthetransmierreactstochangesin

thesystem.Theresponsemeisthemethedevicetakestoreach63%

ofthemeasuredvalue.Tosmoothoutunstablepressureuctuaonsin

airowapplicaons,selectalongerresponseme.

Example:

Selectedresponseme:8.0seconds

Result: Output signal achieves a new value in 40 seconds (Response

me*5)

Tochangeresponseme,installorremovejumperonJ4.

(seeFigure3)

1)InstalljumperonJ4for8.0secondresponseme.

2)RemovejumperfromJ4for0.4secondresponseme.

STEP 6: SELECTING THE RESPONSE TIME

STEP 7: Using 2-10 V output

Insomeapplicaonsitiscricaltoknowimmidiatelyifthewireis

brokenorthedeviceisdamaged.Inthesecases,a2–10voltageoutput

isrecommended.

1)InstalljumperonJ6for2–10voltageoutput

2)RemovejumperfromJ6for0–10voltageoutput

NOTE!WhenusingcurrentoutputJ6circuitmustbeopen!

NOTE! Always zero the device before use.

Tozerothedevicetwooponsareavailable:

1)Autozerocalibraon(manualzeroingnotrequired)

2)ManualPushbuonzeropointcalibraon

a) Disconnect both pressure tubes from the pressure ports labeled +

and –.

b) Push down the zero buon (joysck) unl the LED light (red)

turns on and the display reads “zeroing” (display opon only). (see

Figure 6)

c) The zeroing of the device will proceed automacally. Zeroing is

complete when the LED turns off, and the display reads 0 (display

opon only).

d) Reinstall the pressure tubes, ensuring the High pressure tube is

connected to the port labeled +, and the Low pressure tube is

connected to the port labeled −.

Press down buon

LED turns ON

Display reads “Zeroing”

LED

Figure 4