The PPE must always be worn correctly by the user when entering a hazardous area

as follows: Where applicable, all zippers must be fully closed and all hook and loop flaps

closed fully and flush with no hook or loop portions exposed. Waist straps, where applicable,

must be tightened to fit the user snuggly (or “securely”). The PPE must always fit the user

correctly. If the PPE is either too loose or too tight, the PPE will not provide an optimum

level of protection as the user’s movement and sight may become impeded or the user’s

skin or undergarments may become exposed and unprotected. The integrated hard hat,

where applicable, must be correctly adjusted to firmly fit the user’s head for it to remain

in place for the foreseeable period of use and to allow the user minimal sight and

movement impediment. This is done by turning the black adjustment knob located on

the rear head strap to either tighten or loosen the head strap. All the PPE products are

available in a wide range of sizes to allow the user to choose the correct fit..

Unless otherwise required for your application, hard hats are required when using this PPE to

meet all necessary standards and requirements herein.

The hook and loop fastening the face shield to the fabric hood must be firmly attached and

must fit flush with no hook or loop portion exposed. Front and rear flaps must drop to

the user’s chest and upper back respectively without any hindrance.

NOTE: THE FACE SHIELD AFFECTS COLOR PERCEPTION.

The hard hat must be replaced if subjected to a significant mechanical impact, whether

it results in visible damage or not. No part of the hard hat should be removed or modified in

any way.

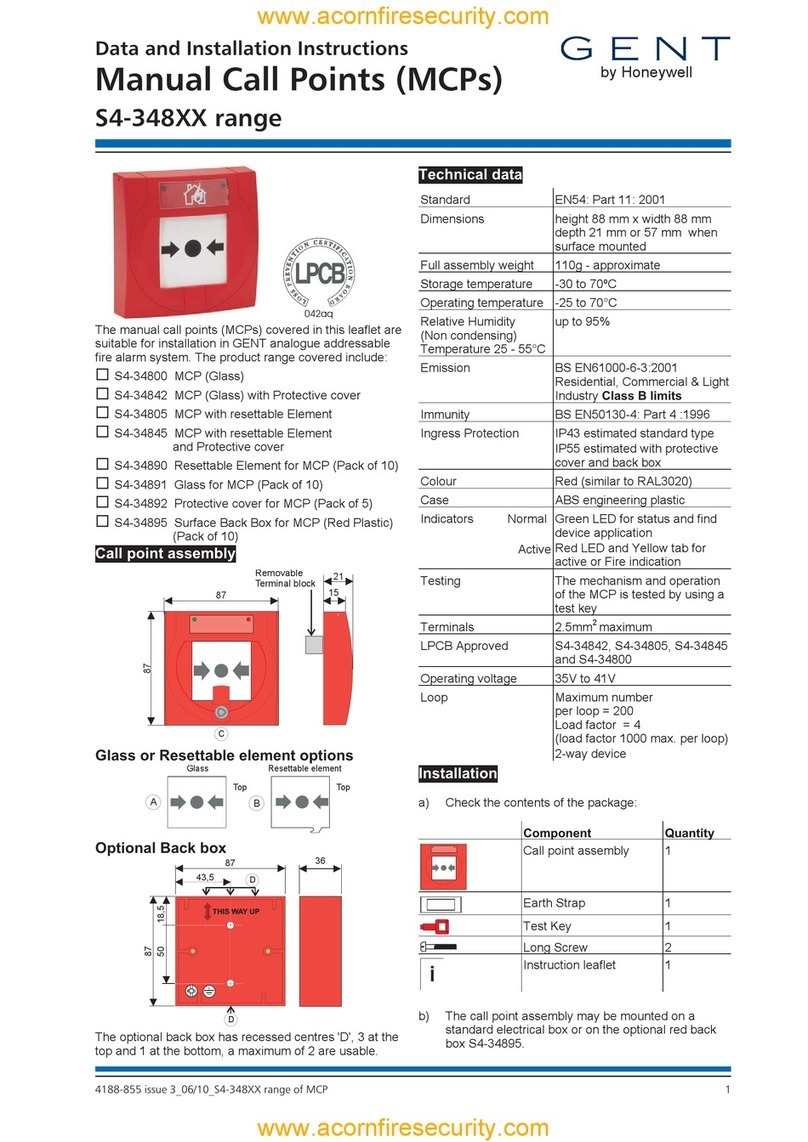

2. CLASSES OF PROTECTION

The PPE is available in the following ATPV classes of protection:

ATPV/EBT CLASSES OF PROTECTION AVAILABLE-cal/cm

2

PPE 8 12 20 40 65 100

Coats • • • • • •

Over Pants • • •

Bib Overalls • • • • • •

Hoods • • • • • •

Coveralls • • •

These ATPV/EBT classes are a result of independent laboratory testing of the PPE to Standard

ASTM F1506 as per Test Method ASTM F1959.

3. CLEANING, MAINTENANCE AND OBSOLESCENCE

(END OF LIFE)

The PPE must be kept clean and dry to provide an optimum level of protection.

NOTE: SOILED PPE REDUCES EFFECTIVENESS OF PROTECTION

The following care instructions apply to the fabric component of the PPE which should

be removed from the shield and hard hat assembly prior to washing. The face shield

must be unfastened and removed prior to cleaning in an ultrasonic bath or with mild

soapy lukewarm water. Dry with cleaning paper or lint free cloth.

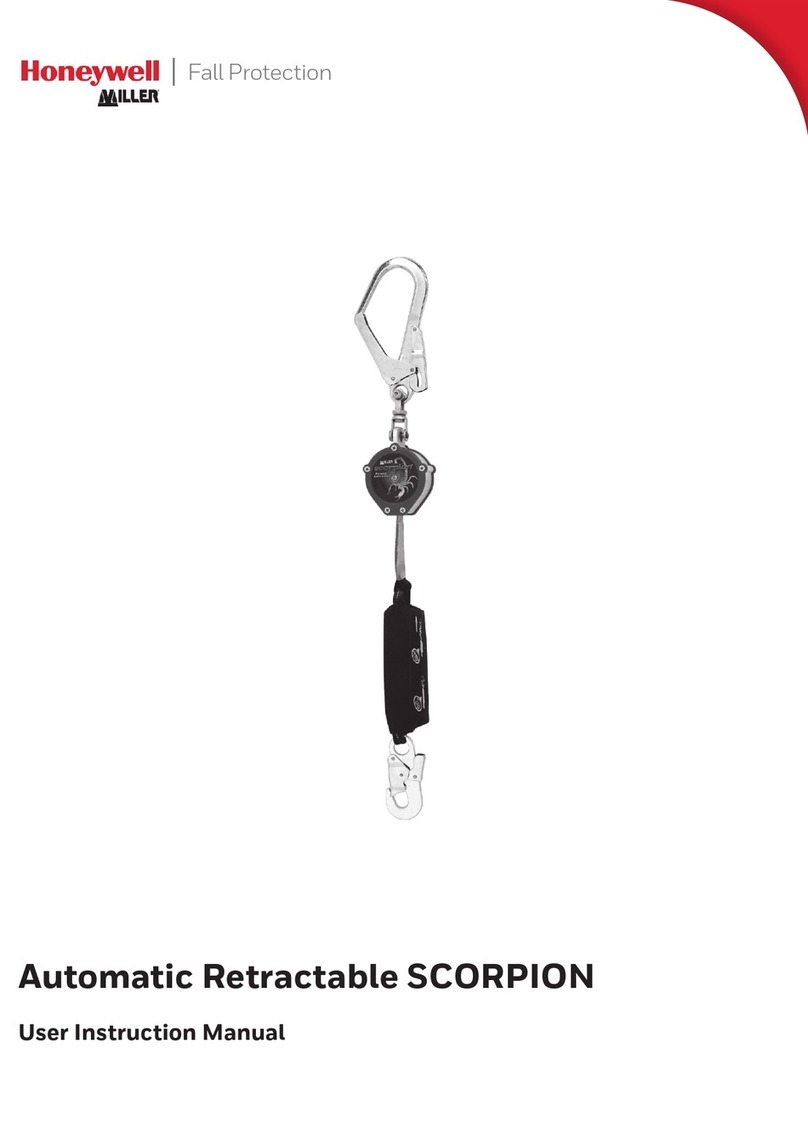

The PPE must not be washed in temperatures over 140ºF (60ºC).

Tumble dry at normal temperature.

Chlorine bleaches such as those containing sodium hypochlorite and oxygen

bleaches such as hydrogen peroxide must not be used to wash the PPE

neither directly nor as an ingredient in detergents, as they may affect

the protective properties of the PPE.

To provide an optimum level of protection, the PPE must be maintained in its original

condition. If the PPE becomes damaged due to factors including but not limited to

rips, cuts, abrasion, perforation, or other incidents that could cause damage but may

not result in visible damage, it may not provide the optimum level of protection and must be

replaced before being used again.

Wear of the face shield due to scratches may cause the user’s vision to become restricted.

Shouldsuch wear become apparent,the face shield must be replaced with an original

Salisbury part listed in section 4 of this document. To replace the face shield in a

PrismShield™ Plus Hood, simply remove the fabric component of the PPE held on with

hook & loop, then un-clip the shield from the hard hat by removing the retaining clips

from both sides.

The expected shelf life of the PPE is five years provided that entire kit is box packed and

all layers of packaging are intact, have never been opened and have never been used.

Each PPE label has the tracking number followed by month and year of manufacturing,

in MM-YY format. The expected service life of product is five years, from the month and

year of first donning, provided that proper care and maintenance instructions are followed

strictly as per the guidelines. Suspend the usage of PPE if you find mechanical damage of

any kind or any other damage during the service life.

Each PPE comes with standard warranty of 12 months from the date of shipment for any

workmanship defects and equivalent PPE will be provided as a replacement.

NOTE: INSPECT THE PPE BEFORE EACH USE. DO NOT ATTEMPT TO USE

THE PPE FOR ITS INTENDED PURPOSE IF ITS CONDITION IS IN DOUBT!

The PPE will maintain its protective properties until its end of shelf life, end of service life,

or until the condition of the PPE is in doubt, whichever occurs first.

4. COMPATIBILITY, ACCESSORIES/SPARE PARTS AND

ASSEMBLY INSTRUCTIONS

The Salisbury Pro-Wear™ Plus Bib Overalls or Over Pants must be used properly with

Salisbury Pro-Wear™ Plus Coats to provide the user with total limb and torso protection

from the thermal effects of an electric arc flash.

The Salisbury Pro-Wear™ Plus Arc Flash Protection Coveralls are intended for use as a

single garment providing the user with both limb and torso protection from the thermal

effects of an electric arc flash.

6 7

60C

25

•

•

•

•

NOTE: THE SUSPENDER MATERIAL OF THE SALISBURY PRO-WEAR

TM

PLUS ARC FLASH PROTECTION BIB OVERALLS MUST ALWAYS BE

COVERED BY A SALISBURY PRO-WEAR

TM

PLUS COAT.