Installation Instructions for the

Key Operated Safety Interlock Switch

Sensing and Control

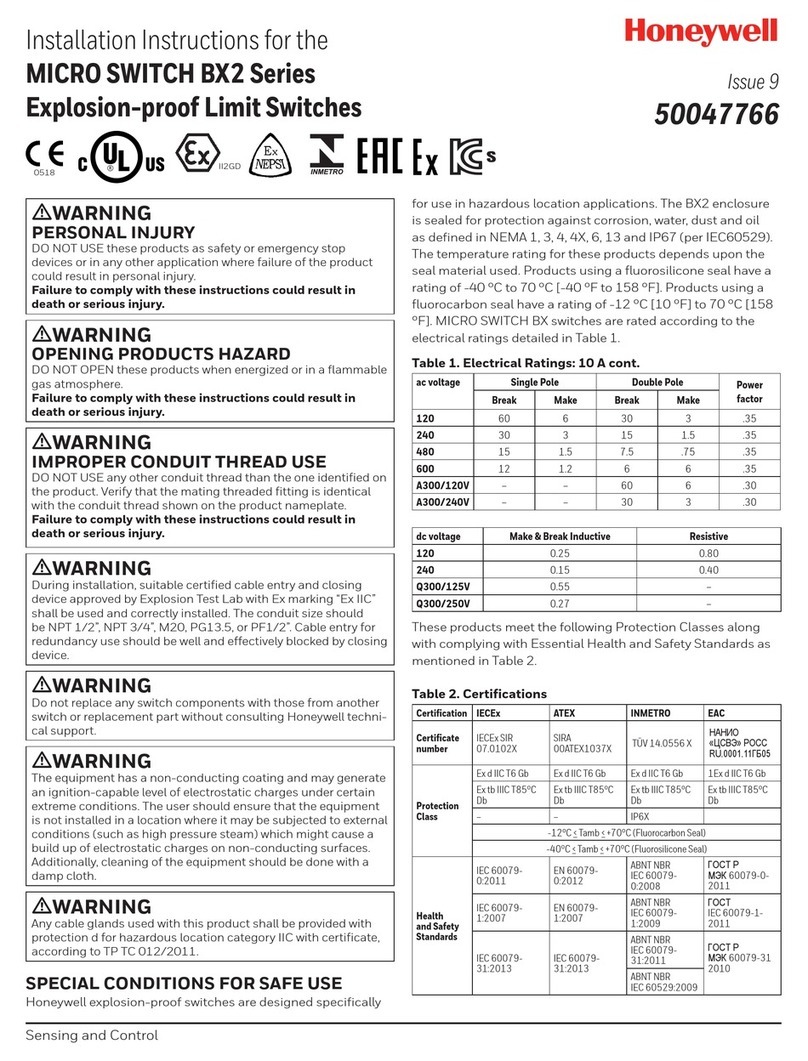

ELECTRICAL DATA

Rated thermal current Ith: 10 A

1AC Designation: A300/A600

2AC Utilization Category: AC15

3DC Designation: Q300

4DC Utilization Category: DC13

Rated Impulse Withstand Uimp: 2500 VDC

Maximum fuse rating: 10 A quick acting

Degree of protection:

IP67; NEMA/UL types 1,4,12,13

Permissible Temperature Range:

Operating: -25° to 85°C (-13°to 185°)

Storage: -40° to 120°C (-40° to 248°)

Conductor cross section (screw connection):

Stranded: 0.75 mm² to 2.5 mm²,

18 to 14 AWG

Solid: 0.75 mm² to 1.5 mm²,18 to 16 AWG

NOTICE

Use 90° C wire when ambient is over 75°C.

This product complies with Machinery Directive

(89/392/EEC as amended by Directive

91/369/EEC) and complies with EN60947-5-1.

Improper installation of this device can cause

personal injury to operating personnel. Strictly

adhere to the following instructions.

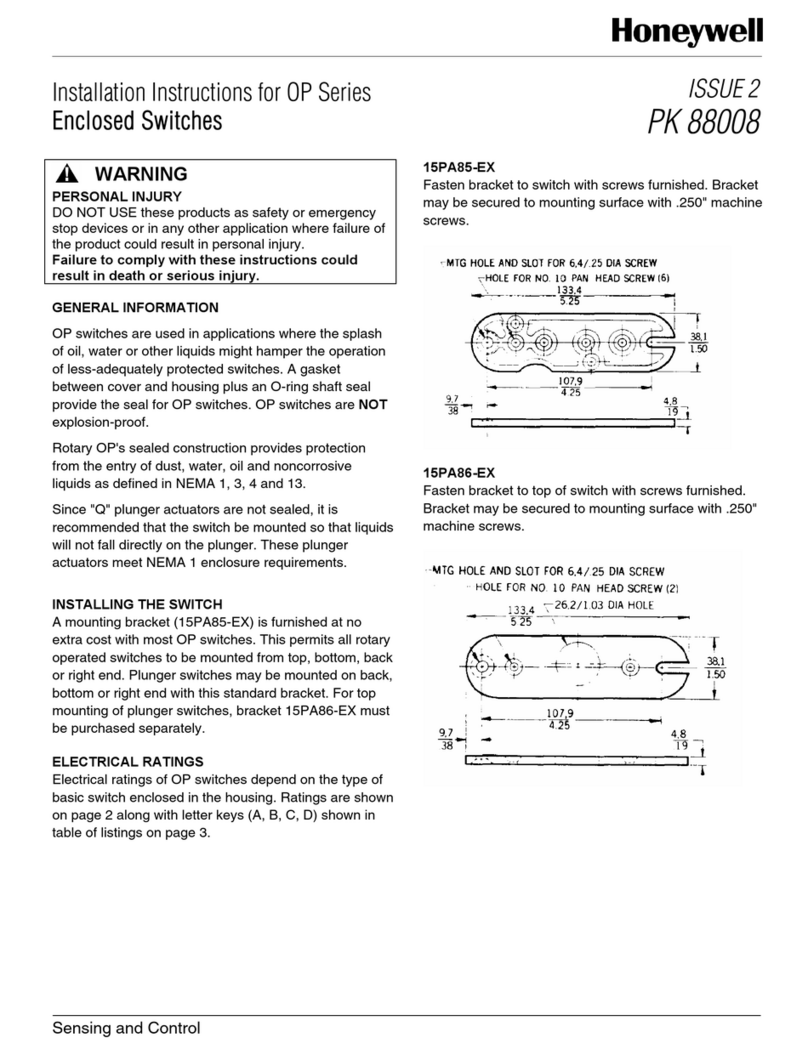

RECOMMENDED TIGHTENING TORQUE AND

SCREW SIZES

• Switch enclosure to mounting surface: 4.9-5.9

Nm (43-52 in./lb) M5 or #10

• Cover to switch enclosure: 1.2-1.4 Nm (10-12

in./lb) M4

• Connector to secure cable to enclosure (if

required): 1.8-2.2 Nm (16-19 in./lb.)

• Operating head to switch enclosure (if

changed): 1,36-1,80 Nm (12-16 in./lb) M4

• Switch terminal screws: 0.8-1 Nm (7-9 in./lb.)

M3

• Ground Screw: .08-1 Nm (7-9 in./lb) M3

• Key to mounting surface: 2.4-2.8 Nm (21-25

in./lb) M5 or #10

CHANGE IN OPERATING HEAD KEY ENTRY

LOCATION

Head options “E and K”are shipped

unassembled from the switch housing and includes

(4) one-way screws for customer assembly:

Properly seat the factory-installed “O”ring in its

seal grove. Determine the required key-entry

location and-to prevent improper access to the

switch mechanism as well as to ensure proper

functioning of the switch-securely fasten the

operating head to the switch housing with the (4)

one-way screws provided and at the recommended

tightening torque shown above. Honeywell’s

MICRO SWITCH Division warranty does not cover

this version unless the one-way screws are

installed.

Operating heads are not available as

replacement parts.

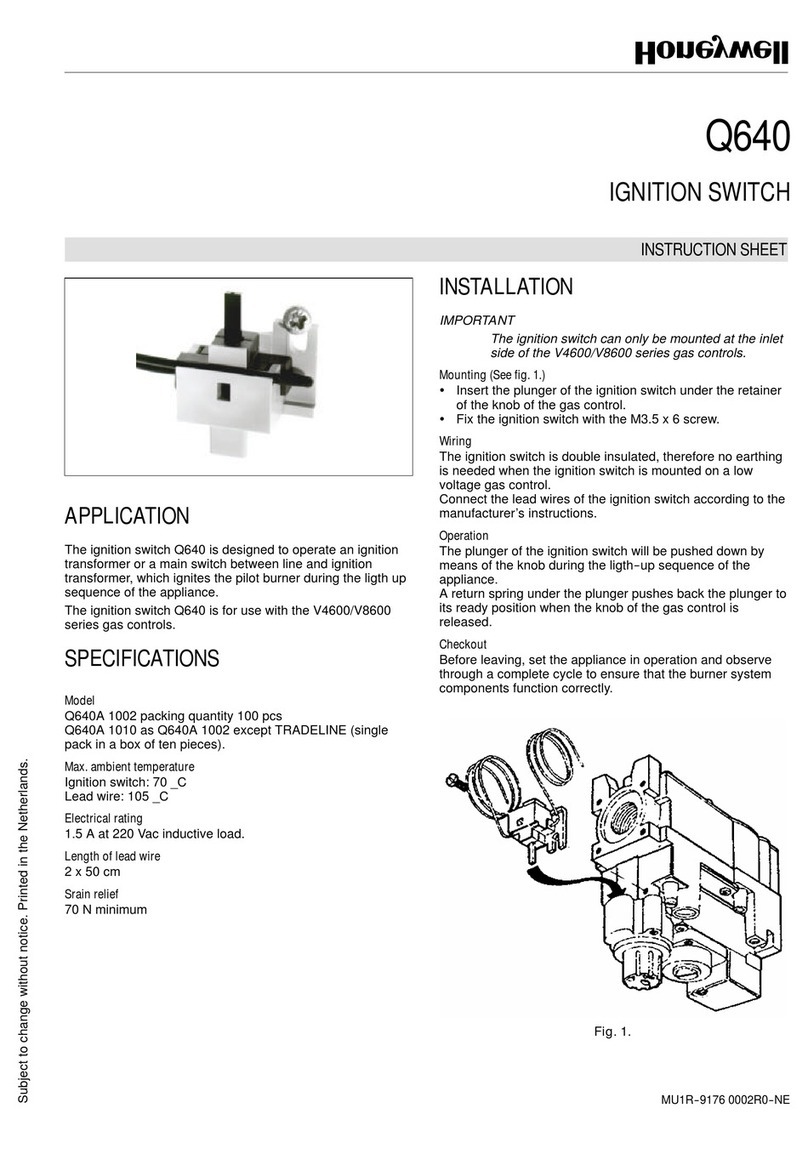

INSTALLATION (See Figure 3)

Switch and key must be assembled together

before mounting to equipment. Provide mounting

holes as shown.

The key must travel to dimension X (Figure 3) to

ensure reliable switch contact transfer. For safety,

the operating mechanism must be moved to this

dimension to ensure the correct operation of the

positive break mechanism, which will ensure that a

contact gap on the switch will withstand the

insulation voltage of 2500V required by IEC 947-5-1

& UL508.

The positive break mechanism will come into

effect on the N.C. (normally closed) circuit when the

key is extracted from its full inward position to the

dimension noted above.

Key actuation force: 22,3 N (5 lb.) max. The

maximum force applied to the key must not exceed

100 N (22.4 lb.) to prevent mechanical damage that

could lead to failure of the switch.

Key extraction force: 2.2 N (0.5 lb.) max. Head

Codes F, G, H, J & K are adjustable up to 13,4 N (3

lb.). Max. key operating speed: 1 m (39 in) per

second.

The key is not intended as a stop for the door.

Ensure that the key is not traveled more than the

maximum total travel shown in Figure 3.