USER MANUAL

HC1151

INDEX

7845436-01 11/18

subject to change without notice

AWARNINGS .....................................................................................................................A.1

A.1PERSONAL PROTECTIVE EQUIPMENT.................................................................................................A.1

A.2MECHANICAL HAZARDS ........................................................................................................................A.2

A.2.1MECHANICAL RESISTANCE ...................................................................................................................A.2

A.2.2CRUSHING HAZARD................................................................................................................................A.4

A.2.3CUTTING HAZARD...................................................................................................................................A.5

A.2.4IMPACT HAZARD .....................................................................................................................................A.6

A.2.5OIL LEAK HAZARD...................................................................................................................................A.7

A.2.6LOSS OF STABILITY ................................................................................................................................A.8

A.2.7SLIPPING AND FALLS............................................................................................................................A.10

A.3ELECTRIC SHOCK HAZARD.................................................................................................................A.11

A.3.1CONTACT WITH LIVE COMPONENTS..................................................................................................A.11

A.3.2STATIC ELECTRICITY............................................................................................................................A.12

A.4HEAT HAZARDS ....................................................................................................................................A.12

A.4.1BURNS ....................................................................................................................................................A.12

A.5NOISE HAZARDS ...................................................................................................................................A.12

A.6VIBRATION HAZARDS ..........................................................................................................................A.13

A.7HAZARDS DUE TO TOXIC SUBSTANCES ...........................................................................................A.13

A.8ERGONOMIC HAZARDS........................................................................................................................A.14

A.8.1MANUAL OPERATIONS .........................................................................................................................A.14

A.8.2VISIBILITY............................................................................................................................................... A.14

A.8.3HUMAN ERROR .....................................................................................................................................A.14

A.9UNEXPECTED START-UP AND SWITCH-OFF OF THE CRANE .........................................................A.15

A.10SAFETY DEVICE FAULTS .....................................................................................................................A.15

A.11COUPLING FAULTS...............................................................................................................................A.17

A.12HAZARDS DUE TO INCORRECT LIFTING OPERATIONS...................................................................A.19

A.13HOW TO TRANSPORT THE CRANE.....................................................................................................A.22

A.14WARNINGS FOR JIB..............................................................................................................................A.23

A.15WARNINGS FOR WINCH .......................................................................................................................A.24

A.16WARNINGS FOR DRILL.........................................................................................................................A.26

BUSER MANUAL...............................................................................................................B.1

B.1PREMISE ..................................................................................................................................................B.1

B.2IDENTIFICATION......................................................................................................................................B.2

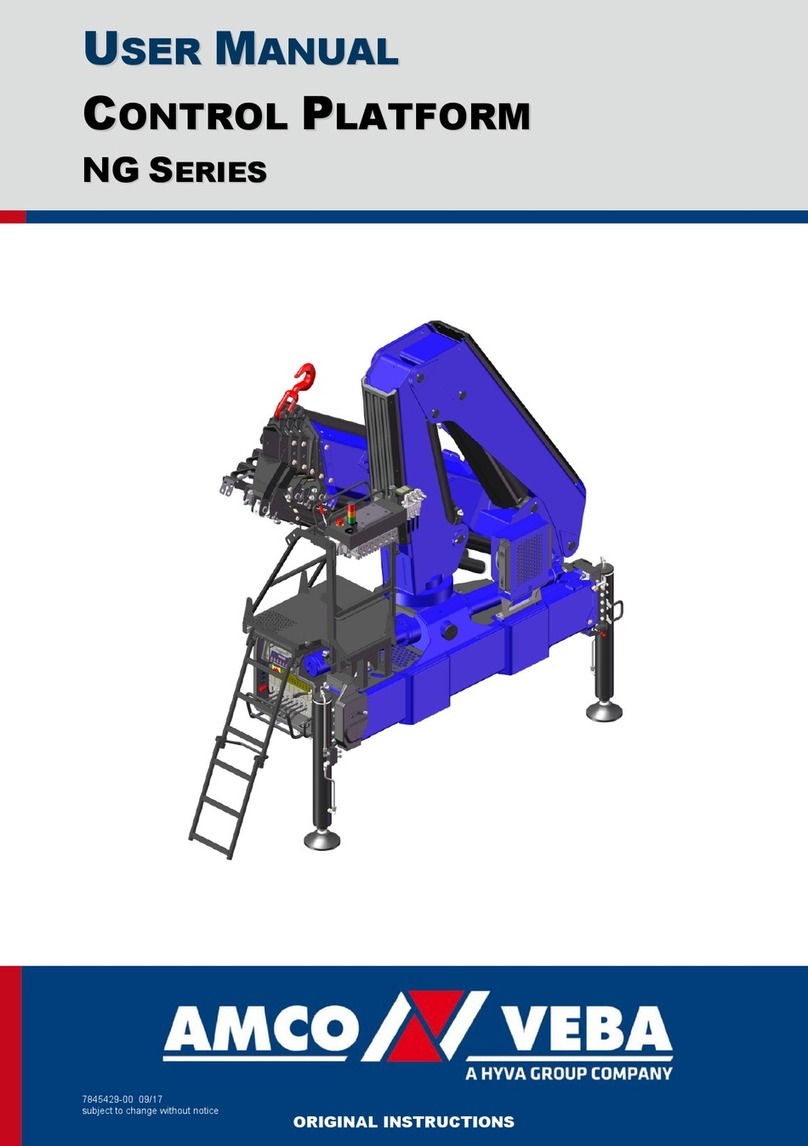

B.3DESCRIPTION AND DOCUMENTATION.................................................................................................B.3

B.3.1ENCLOSED DOCUMENTATION ..............................................................................................................B.3

B.3.2MARK ........................................................................................................................................................B.3

B.3.3SERVICE CONDITIONS ...........................................................................................................................B.4

B.3.4MAIN COMPONENTS ...............................................................................................................................B.5

B.4CONTROLS ..............................................................................................................................................B.6

B.4.1STABILIZERS CONTROLS.......................................................................................................................B.6

B.4.2RADIO REMOTE CONTROL ....................................................................................................................B.7

B.4.3EMERGENCY CONTROLS ON COLUMN.............................................................................................. B.10

B.5SAFETY DEVICES..................................................................................................................................B.11

B.5.1EMERGENCY STOP BUTTON ...............................................................................................................B.11

B.5.2OIL COOLER...........................................................................................................................................B.11

B.5.3LOCKING DEVICES FOR STABILIZERS ...............................................................................................B.12

B.5.4MOMENT LIMITER..................................................................................................................................B.13

B.5.5LIFT CONTROL SYSTEM (LCS).............................................................................................................B.13

B.5.6ROTATION CONTROL SENSOR (HRCS) .............................................................................................. B.14

B.6GAUGES AND INDICATORS .................................................................................................................B.15

B.6.1GAUGES ON OIL TANK..........................................................................................................................B.15

B.6.2OIL LEVEL INDICATOR ON GEAR UNITS.............................................................................................B.16

B.6.3LOAD INDICATOR ..................................................................................................................................B.16

B.6.4VISUAL-AUDIBLE WARNING DEVICES IN CABIN................................................................................B.17

B.6.5WARNING LABELS.................................................................................................................................B.17

B.7OPERATING THE CRANE .....................................................................................................................B.18

B.7.1PRELIMINARY CHECKS BEFORE OPERATION................................................................................... B.18

B.7.2START-UP OPERATION.........................................................................................................................B.19

B.7.3START-UP OPERATION AT LOW TEMPERATURE.............................................................................. B.19

B.7.4HOW TO DEPLOY THE STABILIZERS ..................................................................................................B.20

B.7.5OPENING PROCEDURE ........................................................................................................................B.22

B.7.6HOW TO READ THE LOAD CHARTS ....................................................................................................B.23

B.7.7LIFTING OPERATIONS ..........................................................................................................................B.23

B.7.8CLOSING PROCEDURE.........................................................................................................................B.24

B.7.9HOW TO FOLD THE STABILIZERS .......................................................................................................B.26

B.7.10USE WITH JIB.........................................................................................................................................B.29