43

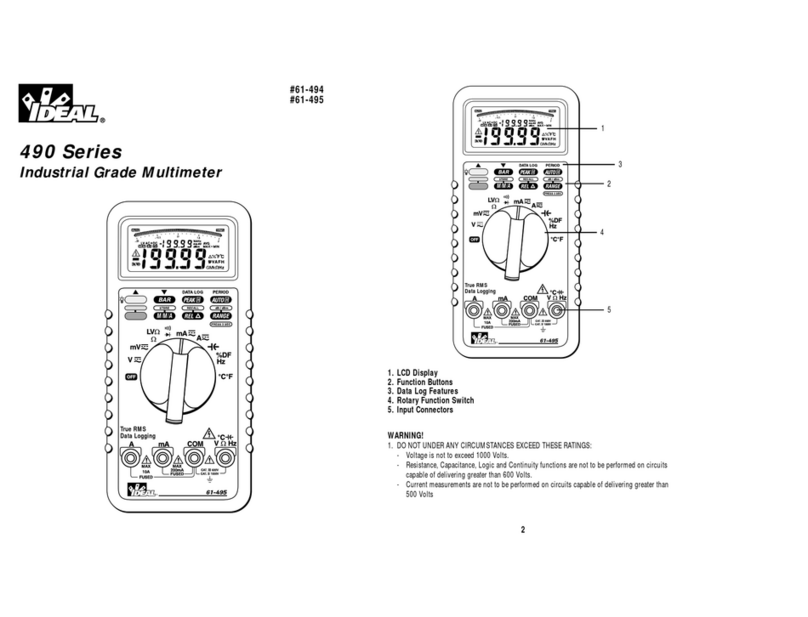

1. Digital Display – The digital display has 4000 counts

LCD readout with 82 segments analog bar graph, auto

polarity, decimal point, “ ” AC, DC RANGE,

APO and unit annunciators.

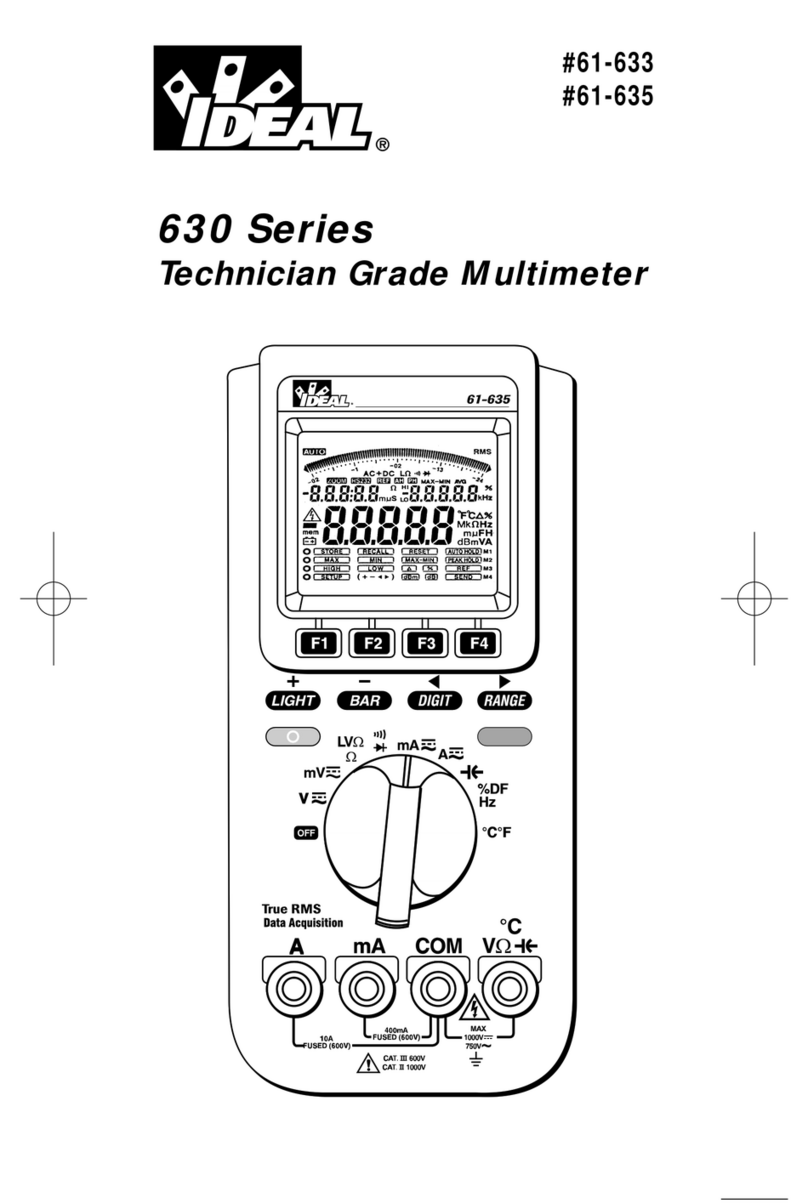

2. Rotary Switch – Select the Function and Range desired.

3. COM Input Terminal – Ground input connector.

4. °C °F VΩHz Input Terminal – Positive input connector

for Volts, Ohms Frequency, and Temperature.

5. mA Input Terminal – Positive input connector for Amp

measurements (up to 400mA).

6. A Input Terminal – Positive input connector for Amp

measurements (up to 10A).

7. Range Switch, (Manual Range) – “Range” switch is

pushed to select manual ranging and to change ranges.

When “Range” switch is pushed on “Range” annunciator on

the LCD appears. Push “ Range ” switch to select

appropriate range to be used. Push “Range” switch and

hold 2 seconds to return to Autoranging.

8. REL (PEAK MIN/MAX) Switch – For resistance,

frequency, capacitance and temperature measurements, this

button enables the relative change function. When pressed

the value is stored, and all new measurements are displayed

as their relative difference from the stored value. In current

and voltage measurements, this button performs a peak

hold finction. The peak hold mode must be calibrated prior

to use. To calibrate the peak hold, press the key until the

meter displays “CAL”. Short the test leads to calibrate.

9. MIN/MAX Switch – Press this switch to toggle between

the minimum and maximum values. Pressing the button for

2 seconds to escape MIN/MAX mode.

10.Hold Switch – This switch is used to hold the measured

value for all functions. The held value is displayed along

with the annunciator. Measurements are made ,but the

display is not updated. This function can be used in

MIN/MAX mode or PEAK MIN/MAX mode.

11.Light Switch – This switch turns the backlight on and off.

12.Blue Switch – Push the switch to measure AC

Voltage/Current or DC Voltage/Current in the

Voltage/Current mode, or to measure Resistance or

Continuity or Diode in Ω/ / mode, or to measure

frequency or RPM in Hz/RPM mode.

WARNING!

1. DO NOT UNDER ANY CIRCUMSTANCES EXCEED THESE

RATINGS:

• Voltage is not to exceed 1000 Volts.

• Resistance, Capacitance, Logic and Continuity functions

are not to be performed on circuits capable of delivering

greater than 600 Volts.

• Current measurements are not to be performed on

circuits capable of delivering greater than 500 Volts

2. To avoid electrical shock hazards and/or damage to the meter:

• Do not exceed the voltage ratings for the meter. Use

caution when measuring voltage.

• Do not use during electrical storms. AC power sources

with inductive loads or electrical storms may result in

high voltage. High energy transients can damage meter

and present a dangerous shock hazard.

• Turn off power to the circuit or device being measured

before taking resistance and capacitance measurements.

Fully discharge all capacitors before measuring.

3. Ensure meter is in proper working order before using.

Visually inspect meter for damage. Performing a continuity

check can verify proper operation. If the meter reading goes

from overload to zero, this typically means the meter is in

proper working order.

4. Visually inspect leads for damage before using. Replace if

insulation is damaged or leads appear suspect.

5. Never ground yourself when taking electrical measurements.

Do not touch exposed metal pipes, outlets, fixtures etc.

Keep your body isolated from ground by using dry clothing,

rubber shoes, mats, or any other approved insulating

material. Keep your fingers behind the finger guards on the

probes. Work with others.

6. Before beginning all unknown measurements, set meter to

highest possible range.

7. Before breaking a circuit for testing, turn off the power to the

circuit. When disconnecting from a circuit, disconnect the

hot lead first, then the common lead.

8. Disconnect the meter from the circuit before turning off any

indicator, including motors, transformers, and solenoids.

H

H