4

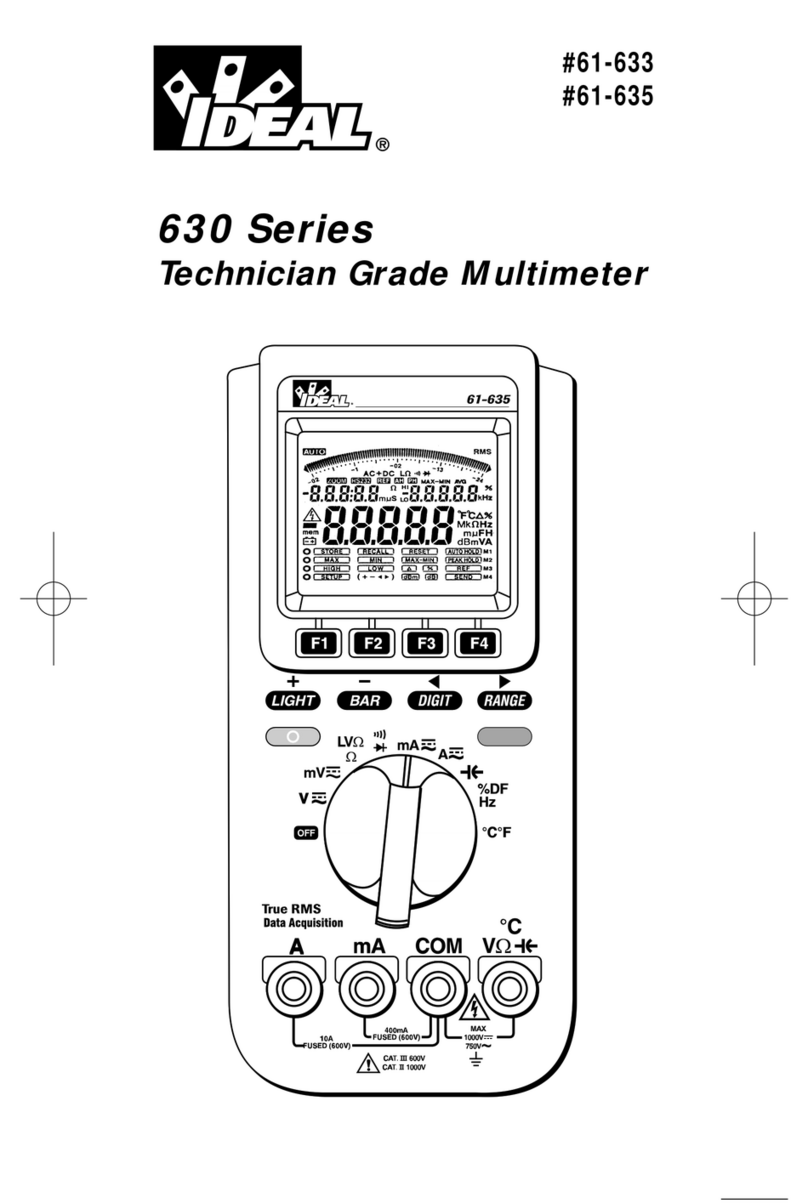

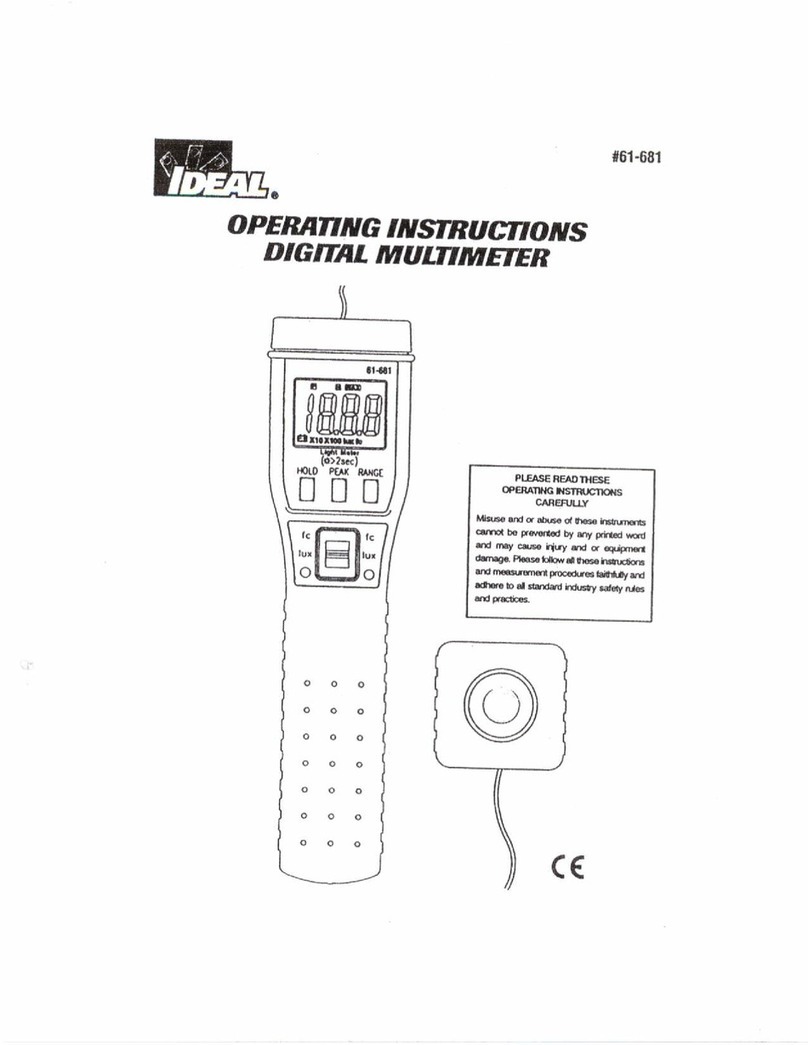

Function Buttons

The meter beeps once for every valid key-press, and beeps

twice for every invalid key-press.

Backlight Button

• The light button is used to turn the backlight on or off.

~ Hz Button

• Pressing the ~Hz button in AC voltage or current mode

enters frequency counter mode with automatic range

selection.

• Pressing range switch in VAHz mode also changes the full

scale range of the original voltage or current mode after

VAHz mode is cancelled.

Peak Hold Button

• The peak hold button toggles the peak hold function on or

off.

• The precision of peak hold measurement can be enhanced

by calibration.

• Peak hold can be calibrated by pressing the peak hold but-

ton for > 2 seconds. “caL will be shown on the main dis-

play.

• Press the peak hold button to toggle between PMAX and

PMIN.

• Press peak hold for > 2 seconds to escape the peak hold

measurement.

Range Button

• Pressing the range button changes the unit to manual

ranging and toggles between the ranges of the measure-

ment function.

• Pressing the range button for > 2 seconds returns the unit

to auto ranging.

Blue Button

• The blue button toggles between the black and blue func-

tions on the dial.

3

WARNING!

1. DO NOT UNDER ANY CIRCUMSTANCES EXCEED THESE

RATINGS:

- Voltage is not to exceed 1000 Volts.

- Resistance, Capacitance, Logic and Continuity func-

tions are not to be performed on circuits capable of deliv-

ering greater than 600 Volts.

- Current measurements are not to be performed on cir-

cuits capable of delivering greater than 500 Volts

2. To avoid electrical shock hazards and/or damage to the

meter:

- Do not exceed the voltage ratings for the meter. Use

caution when measuring voltage.

- Do not use during electrical storms. AC power sources

with inductive loads or electrical storms may result in high

voltage. High energy transients can damage meter and

present a dangerous shock hazard.

- Turn off power to the circuit or device being measured

before taking resistance and capacitance measurements.

Fully discharge all capacitors before measuring.

3. Ensure meter is in proper working order before using.

Visually inspect meter for damage. Performing a continu-

ity check can verify proper operation. If the meter reading

goes from overload to zero, this typically means the meter

is in proper working order.

4. Visually inspect leads for damage before using. Replace if

insulation is damaged or leads appear suspect.

5. Never ground yourself when taking electrical measure-

ments. Do not touch exposed metal pipes, outlets, fixtures

etc. Keep your body isolated from ground by using dry

clothing, rubber shoes, mats, or any other approved insu-

lating material. Keep your fingers behind the finger

guards on the probes. Work with others.

6. Before beginning all unknown measurements, set meter to

highest possible range.

7. Before breaking a circuit for testing, turn off the power to

the circuit. When disconnecting from a circuit, disconnect

the hot lead first, then the common lead.

8. Disconnect the meter from the circuit before turning off

any indicator, including motors, transformers, and sole-

noids.