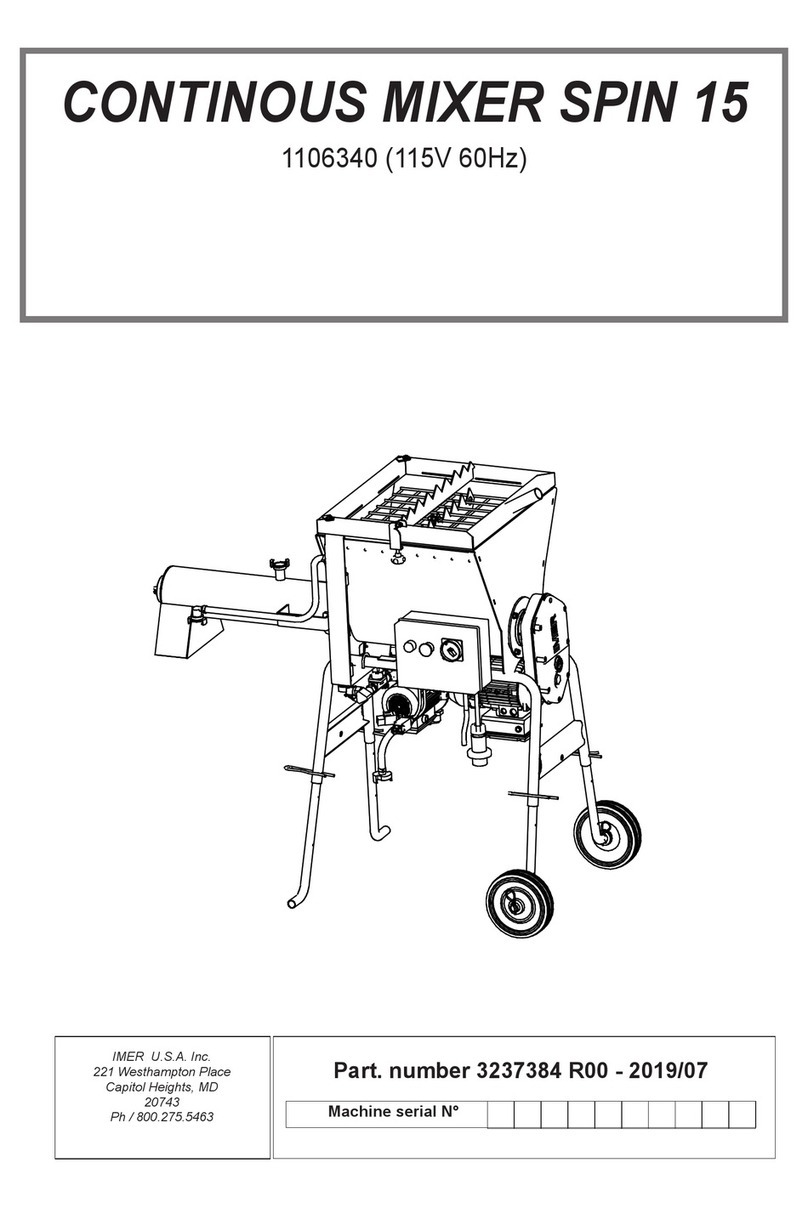

IMER Workman 350 II Datasheet

Machine serialN°

ManualPart.number 3209281_R05 -2005/03

U.S.A. inc.

WORKMAN 350 II MULTIMIXER

R

MANUAL INSTRUCTION

and

PARTSLIST

Model1105855

Writeinthe serialn° ofyuor machine here

IMER U.S.A. Inc.

-2-

WORKMAN350IIMULTIMIXER

Thank-youforpurchasing aWorkman350IIfroman ImerU.S.A.dealer.Yourdecisionisan

intelligent one.

There isno other concretemixerin theworldwhichdeliversthe benefits and featuresofthe

Workman350II.

-Extremelyrigid,migwelded barsteel frame.

-5.5H.P.Honda withlowoil alert.

.-Fullwidthfenders.

-TorsionBarsuspension.

-Advancedrumandpaddledesign,excellentmixinganddischargeaction.

-Telescopicfootstandswhichprovideadditionalstabilityduringoperation.

AtImer U.S.A.wecontinuallysearchforwaystobetter serveourcustomers. Shouldyouhave

an idea orthoughttosharewithusregarding thisproductwewould appreciatehearing from

you.Ourmottois"ToolsandServicesforthe 21stCentury". Welookforwardtodelivering

thegoods.

Thankyou again for yourpurchase.

MaceT.Coleman,Jr.

President, ImerU.S.A., Inc.

IMERUSAWEST

3654EnterpriseAvenue

Hayward,CA94545

TollFree:(800)275-5463

Office:(510)670-7970

Fax:(510)783-4255

IMERUSAEAST

221WesthamptonPlace

CapitolHeights,MD20743

Tel:301 -336 -3700

Fax: 301 -336 -6687

IMER U.S.A. Inc.

-3-

WORKMAN350IIMULTIMIXER

IMERU.S.A., INC.

WORKMAN 350 II MULTIMIXER

INSTRUCTIONMANUAL

NOTE: Pleaseread thismanualbeforebeginning to

assemble or operatethispieceof equipment.

ASSEMBLY........................................................................................4

IMPORTANT NOTESANDADVICE..................................................5

OPERATINGINSTRUCTIONS...........................................................7

MAINTENANCE..................................................................................8

BASIC TROUBLE SHOOTING -TECHNICALSPECIFICATIONS...10

SPARE PARTS...................................................................................11

IMER U.S.A. Inc.

-4-

WORKMAN350IIMULTIMIXER

ASSEMBLY

+

TOWING

Essentiallythe Workman 350 II isfullyassembled and readytooperatewhen itleavesthe assembly

facilityhereatImerU.S.A.However,thereareacoupleitemswhichshouldalwaysbe checked before

towingtheWorkman350II.

1.Makesureeachtireisinflated to50 PSI (cold),and check the oil level ofthe Honda motor.

2.Makecertain the retractable stability legsareraised up fullyand locked in placewiththe anchor

pin provided.

3.Makecertain thatthe towbarisproperlyanchored and itstowchain isin place.It isalsoimportant

toloop the towchain around the towbarseveral timesbeforeconnecting ittoavehicle.

4. Makesurethe engine canopy doorislatched shut.

5.Makecertain thatthe hitchsystem on yourcarortruck iscompatible tothe towbartongue.

6.Finally,local lawsand ordinancesvaryfrom statetostateregarding theregistration oftowable

construction equipment, check and see ifalicenseplateisrequired.Call yourlocal Departmentof

MotorVehiclesforthe properproceduretofollow.

NOTE

Statelawmay alsorequire atail light assembly.

Check withyourlocal DepartmentofMotorVehiclesforthe properproceduretofollow.

IMER U.S.A. Inc.

-5-

WORKMAN350IIMULTIMIXER

IMPORTANT NOTESANDADVICE

Do'sand Don'tson theSafeUse

of theWorkman350 II

Inthe interestofsafety,whoeverusestheWorkman350 II shouldfirstread thismanualandbecome

familiarwithall ofthe importantsafety notes. Failure tofollowthisadvicemayresultin injury to

yourselfand others.

WHATTODO!

-Carefullyreadandunderstandtheseinstructionsbeforeoperatingthemixer.ReadtheHondamanual too.

-Alwaysturnofftheengineanddisconnect the spark plug wirebeforecleaningormaintainingthemixer.

Mixerspoweredbyelectricmotorsshouldbeunpluggedfromtheirpowersourcebeforeservicingis

performed.

-Makesurethe safety guardsarealwaysin place.

-Whenusingthemachinealwayswearsafetybootswithreinforced toe-caps,safety glasses,gloves,

hardhat,andclothingwiththeappropriatefit.Looseclothingcancauseinjuryshoulditbecomeentangled

withthe mixer.

-Practicestarting and stopping the machine.

-Keep themixercleanandfreeofdebrisbuild-up.

-Periodicallyinspectyourmixerforabnormalwearordamage.

-Alwaysstoptheenginebeforeaddingfuel.

-Donotoperatethemixerwhileundertheinfluenceofdrugsoralcohol.

-Alwaysoperatethemixeronalevelsurface.

-Whenloading theWorkmanitisthe besttopouryourbaggedmaterial intoa5gallonbucketthenpourit

intothe drum.

-It ismucheasieron yourbodyand safertoo toload the drum in thismanner.

IMER U.S.A. Inc.

-6-

WORKMAN350IIMULTIMIXER

IMPORTANT NOTESANDADVICE

WHATNOTTODO!

DONOT

Placeyourhandsoranyotherobjectinside the mixerdrum while itisrunning.

DONOT

Placeanytoolsorotherobjectsin oraround the mixerdrum while itisrunning .

DONOT

Operatethemixeron asurfacethatisUNEVEN....iftheWorkman isplaced onanincline,itcan fall over

orrollaway.

DONOT

Clean,assemble orwork on the mixerwhile itisplugged in !

DONOT

Operatethemixerinoraroundwaterpuddles!

DONOT

Leavethemixerunattended!

DONOT

Allowotherpersonsaroundthemixerwhileitisoperating

DONOT

OperatetheWorkmanII350ifyouare uncertainastohowtorunthemachine....ContactyourlocalImer

DistributororcallImerU.S.A.at(800)275-5463

DONOT

Operatethemixerwhileundertheinfluenceofdrugsoralcohol!

WEWANTSAFEAND EFFICIENT

PRODUCTION/OPERATION

FORALLOURCUSTOMERS!

IMER U.S.A. Inc.

-7-

WORKMAN350IIMULTIMIXER

OPERATINGINSTRUCTIONS

1.Beforestartingthe enginereadtheHondamanual providedandbecomefamiliarwiththeGX160

powerplant. Especiallyimportantistocheck the oil level dailyand change itmonthly.Additionally,

cleaningtheairfilterweeklyensuresconsistentlygoodperformance.

2.Operatethe the Workman II 350 on alevel surface.Foradditional stability the telescopicfootstands

can be lowered and locked intoplace.

3.Toputthedrumin the loading positionrotatethe dumpwheel until thedesired drumpositionis

achieved.

4.Startthe engine and setthe throttle at3/4tofull on.

5.Nowadd1/2ofthe waterwhichwill berequiredandthen begintoadd the cementandaggregates.

Additional water canbe addedasthecementand aggregatesmixtogether.

BE CAREFUL ! Do Not put your shovel or your hands inside the drum !

6.Toputthedrum inthedischarge position rotatethedump wheeluntillthedesireddrum position

isachieved.

7.During the loading,mixing,and discharge cycle itisimportanttokeep the mixerrunning atall times.

8.Alwaysprepareyourworksitetohavealevel ground surface,theMixermustbe stableasyouloadand

dischargethe drum.

IMER U.S.A. Inc.

-8-

WORKMAN350IIMULTIMIXER

MAINTENANCE

Lubrication

1.Alltheother componentsonthemixerwhichengageor movebackandforthshouldbe lubricatedwitha

lightaerosol type lubricanton aweeklybasis.WD- 40 works well forthisapplication.

2.Essentiallythegearboxissealedforlife.Thequality ofthegearsandthelubricantaresuchthatchanging

the oil is notnecessary.If you wanttochange the oil,see your dealeror call IMER U.S.Adirectlyfor

instruction.

3.Oneayearremovethecastcapfromthetop halfofthedump gearassemblyand greaseitup good.

(Part#36,page 12)

BeltTension

1.The mixerhastwobelts: one in the canopyand the otherin the arm.The beltsareproperlyadjusted

beforeleaving ourfactory,however,itisagoodidea tochecktheirtensionbeforeoperating themixer.

Then,when one beltbecomesloose,tighten itback tothisoriginal condition.

NOTE

Thebeltswillstretchthemostduring thefirstfew

hours ofoperation....check them frequently,and

always kill themotorand disconnectthespark plug

wire beforetouching thebelts. Or,ifyourmachinehas

an electric motor,unplug itfromthepowersource

beforeadjustingthe behs.

2.Totightenthebeltinside the canopyloosen the boltswhichanchor themotor mountplateto

themixerframe.Thisallowsthe motormountplatetoslide down theframe,whichin turn

tightensthe belt.Thebeltshould have1/4"to3/8"of play.Now re-tighten the boltswhich

anchor themotor mountplate.

3.Totightenthe beltinside the armloosen the4nutswhichanchor thegearboxonthe arm.

Tighten the beltbyturningthe adjustment bolt. The beltshould have1/4"to3/8"ofplay,do

notovertighten asthisshortenstheir drivelife.Now re-tighten the gearboxanchorbolts.

IMER U.S.A. Inc.

-9-

WORKMAN350IIMULTIMIXER

NOTE

It isvery important to keeptheenginepulley and the

drive pulley in linewith oneanother.Failure to

maintain thisalignment will cause thebelt to twistand

thenbreak.

WheelBearings

1.Thewheelbearingsshould becleaned and repacked every6monthsto1year.The interval being

dependantupon the amountoftimethe machineistowed,and under whatconditions.This

maintenanceprocedureisthesameasthatforautomotivewheel bearings.

Engine

Read the Hondamanual carefully... and followtheirinstructions.

Changingtheoilandcleaningtheairfilterfrequentlyensureareliableandlonglastingmotor.

Whenyou mayneed HondaEngineServiceorWarrantyAssistance,takethe machine toyourlocalHonda

powerequipmentdealer,theywillhonor the warrantythroughoutAmerica.

NOTE

It isalways agood idea to check theoil levelin the

enginecrankcase atthestartof eachworking day.

Cleanoil atthecorrectlevelmakes foraenginethat

will lastand last.

Mixer’sdrum disassemblyand re-assembly

Incaseit’snecessarytoremovethe drum,toresetitit’snecessary.

-toclean carefullythe gearshaft cone and the drum cone.

-toplacethe drum on the shaft cone,making surethatshaft shearpin isinside itsseatin the drum cone.

-toblockdrum tightingscrewwithwasherbyfollowing tightingtorques:

Workman 350 II:300 ±20 Nm.

MISC.

Everymonth check all themixer's mounting hardwareto

ensureall thenutsand boltsareproperlytightened.

IMER U.S.A. Inc.

-10 -

WORKMAN350IIMULTIMIXER

TECHNICALSPECIFICATIONS

WORKMANII 350

*Capacity based upon usable volume

Dueto Imer U.S.A.'scommitment to

Reasearchand Development,

specificationsare subject

to changewithout notice.

Drumcapacity 12.5CU.FT.

BatchOutput 9.5CU.FT.(1.5bag)*

1/3ofacubicyard

DrumDiameter 32.5Inches

DischargeOutletHeight 26.5Inches

PneumaticWheels 4.50-10Inches(50PSI)

Powerplants 5.5HPHondaGX160

2.0HP electric

Overall OperatingDimensions 79"x50" x66"

Overall StorageDimensions 79"x50" x66"

Weight 545LBS (248 Kg)

IMER U.S.A. Inc.

-11 -

WORKMAN350IIMULTIMIXER

SPARE PARTS

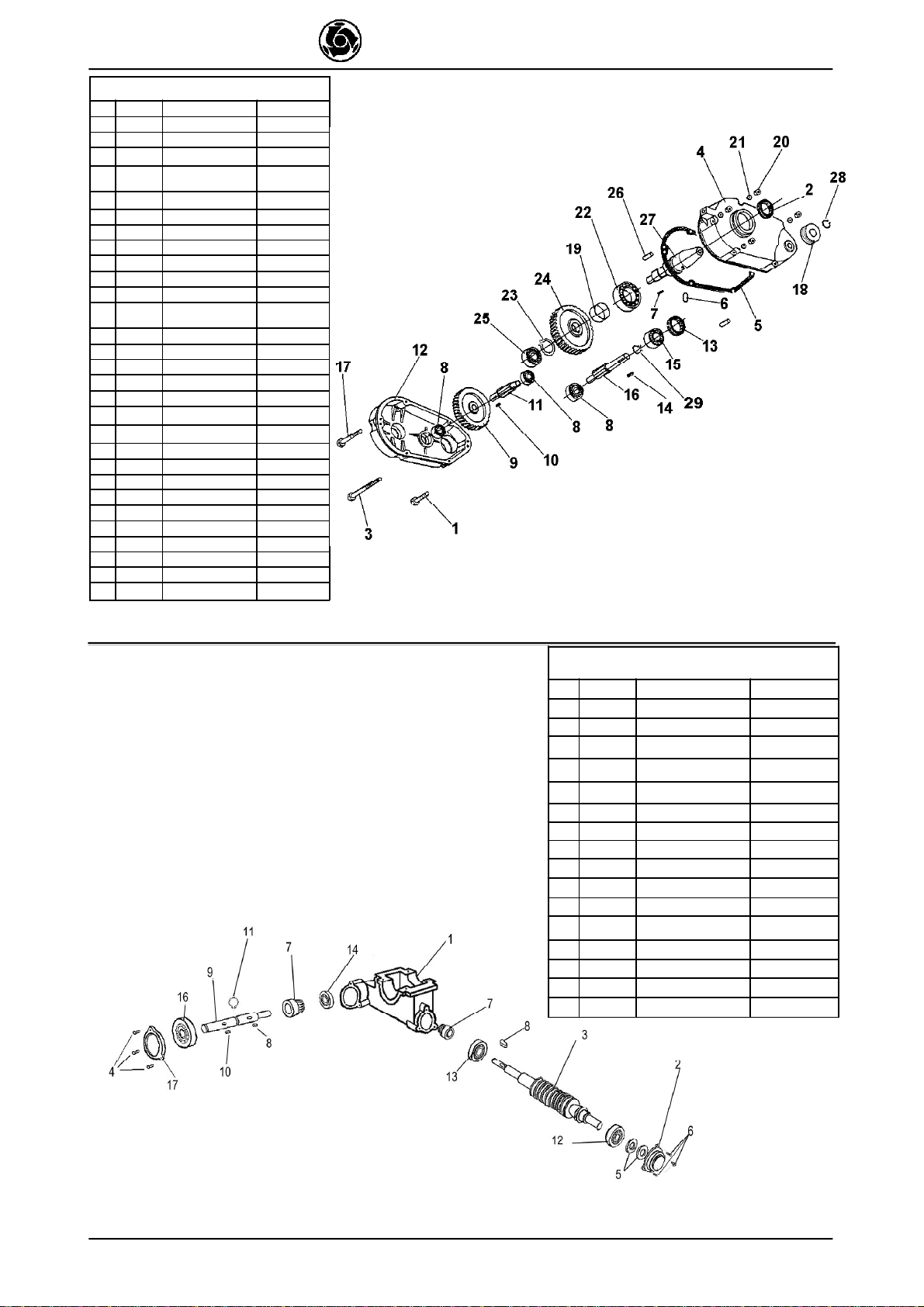

DRAWING1.3(WORKMANII350 CONCRETE MIXER -1105855)

Ref. P.n. MainDescription NOTES

13209275 MAINFRAME

23209277 TOWBAR

33209183 ARM

43206635 DRUMASS'Y

53210467 T-BOLT

63210466 T-BOLT WASHER

73209954 STABILIZINGFOOT

83209009 NYLON FIBERBUSHING

92227205 CIRCLIP E50

10 3209032 PLASTIC PLUG

11 3209298 HONDAMOTOR GX160KI

12 3209165 MOTOR PULLEY

13 2224190 WASHER 8X30X5

14 2210950 MOTOR BELT

15 3209121 BELTGUARD

16 2248216 TORSION BARAXLE

17 3209279 LEGFRAME

18 3209274 REARLEGFRAME

19 3210476 GEARBOX

20 2223980 WHEELNUT

21 2223920 SELFLOCKING NUT M10

22 1222694 BOLT M10X110 Z

23 2227320 CIRCLIP E20

24 3209091 GEARBOXBELT COVER

25 2222420 BOLT 4,8X13

26 3210606 BOLT M10X160Z

27 3208776 KEYWAY 14X9X25

28 3208770 BUSHING

29 3208773 DUMPGEAR Z32

30 2211407 TIRE+WHEEL

31 3206704 ANCHOR PIN

32 3208789 BUMPERPAD

33 3208790 BUMPERPAD

34 2224220 WASHER D10X40

35 2223923 SELFLOCKING NUT M8Z

36 3213876 CASTCAP

37 2222181 BOLT

38 2223921 SELFLOCKING NUT

39 3209786 DUMPGEARCASTING

40 2229300 KEYWAY 6X6X20

41 2224204 WASHER D8X24

43 3208777 DUMPWHEEL

44 3206748 DUMPHANDEL

45 2223923 SELFLOCKING NUT M8Z

46 2222056 BOLT M10X25 Z

47 3209081 BELT-GEARBOXDRIVE 580 J6

48 3209280 SAFETYLABEL

49 3208916 ROLLERSHAFT

51 3209178 WASHER D10X30X4Z

52 2257706 LEGCAP

53 3209468 ANCHOR PIN

54 2226700 SPLITPIN

55 3210560 ENGINEMOUNTINGFRAME

56 3209193 ENGINEMOUNTINGPLATE

57 2222145 BOLT M10X80 Z

58 3208915 ROLLERGUIDE

59 2204421 ROLLERBEARING 6201 2RS

60 1227330 CIRCLIP E15

61 2204438 DRIVE SHAFTBEARINGS 6004 2RS

62 3208919 GEARBOXDRIVEPULLEY

63 3209055 SPACER

64 3203117 KEYWAY 5X5X20

65 3209074 SHAFT

67 3209053 ENGINEPULLEY

68 3208935 CANOPYDOOR

69 3209520 CANOPYREAR

70 3209196 MOUNTING BRACKET

71 2221994 PULLEYBOLT 5/16"X25 Z

72 3209136 ENGINEPULLEYGUARD

73 3209111 LOCK LEVERROD

74 2222190 BOLT M8X40 Z

77 3209195 DUMPARMPLUG

78 2222091 BOLT M8X70 Z

79 3205544 KILLBUTTON

80 3206011 FENDER

81 2222146 BOLT

82 3207782 FENDERARM

83 2222060 BOLT

84 2235452 PLUG

85 3206855 BOLT

87 3206861 AXLEMOUNTING SPACER

88 2223929 NUT

89 2234861 TOWCHAIN

90 2292298 QUICK CLIP LATC

IMER U.S.A. Inc.

-12 -

WORKMAN350IIMULTIMIXER

DRAWING 1.3WORKMAN II 350 CONCRETE MIXER

IMER U.S.A. Inc.

-13 -

WORKMAN350IIMULTIMIXER

TABLE2-GEARBOX-WORKMANII 350

(COD.3210476)

RIF. COD. GB NOTE

1 2222148BOLT M10X65Z

23213179OILSEAL 90X65X10

32222153BOLT M10X100Z

43209515GEARBOXCASE

53209811GEARBOXGASKET

63213177SHEARPIN

73213178KEYWAY 10X8X20

8 3209682BEARING 6302

93209801GEARWHEEL Z.79

10 2229259KEY 6X6X14

11 3208975PINIONGEAR Z11

12 3209514GEARBOXCASE

13 3200094OILSEAL 35X20X7

14 2229250KEY 5X5X15

15 3208983BEARING 6204

16 3209799PINIONGEAR Z9

17 2222145BOLT M10X80Z

18 3208919PULLEY

19 3208966SPACER

20 2223650NUT M10Z

21 2224340WASHER D=10 Z

22 2204569BEARING 6211

23 2227207CIRCLIP E55

24 3208970GEAR Z76

25 3213282BEARING 6208SKF

26 3213180LOCATINGPIN D=8X30

27 3210474DRIVE SHAFT

28 1227330CIRCLIP E15

29 2227320CIRCLIP E20

TAV.8-DRUMREDUCTIONUNIT -

WORKMANII350 (COD.3209786)

RIF. COD. DESCRIPTION NOTE

13209428GEARBOXCASE

23209430COVER

33213893DUMPGEAR M10X110Z

42222465BOLT M5X15 Z

53213811OILSEALRING 47X17X7

63209728SCREW M6X15

7 3213264PINIONGEAR Z20

8 2229259KEYWAY 6X6X14

9 3208771SHAFT

10 2229300KEYWAY 6X6X20

11 2227320CIRCLIP E20

12 3208952BEARING 6206 2Z

13 2204391BEARING 6205 2Z

14 2204484BEARING 6203 2Z

16 2204560BEARING 6204 2RS

17 3209431COVER

IMER U.S.A. Inc.

-14 -

WORKMAN350IIMULTIMIXER

3654EnterpriseAvenue

Hayward,CA94545

TollFree:(800) 275-5463

Office:(510)670-7970

Fax:(510)783-4255

U.S.A. INC.

IMER

EQUIPMENT WARRANTY

U.S.A. INC.

Wewarranttothe original purchaserthattheIMERequipmentdescribed herein (the"equipment")shall be

free from defectsin material and workmanship undernormal useand serviceforwhichitwasintended for

period ofone (1) yearfrom the dateofpurchasebythe original purchaser.

Ourobligation underthiswarranty isexpresslylimited toreplacing orrepairing,free ofcharge,F.O.B. our

designated servicefacility,suchpartofthe equipmentasourinspection shall disclosetobe defective.

Partssuchasengines,motors,pumps,valves,electricmotors,etc.furnished byus,butnotmanufactured

byus,will carryonlythe warranty ofthe manufacturer.Transportation chargesordutiesshall be borne by

purchaser.Thisshall be the limitofourliability withrespecttothe quality ofthe equipment.

Thiswarranty shall notapplytoanyequipment, orpartsthereof, whichhasbeen damaged byreason of

accident, negligence,unreasonable use,faulty repairs,orwhichhasnotbeen maintained and operated in

accordancewithourprinted instructionsforthe equipment. Further,thiswarranty isvoid ifthe equipment,

oranyofitscomponents,isaltered ormodified in anyway.

THIS WARRANTYIS EXPRESSLYINLIEUOFALLOTHERWARRANTIES,

EXPRESSEDOR IMPLIED,INCLUDING ANYIMPLIEDWARRANTYOF

MERCHANTABILITYOR FITNESS FORAPARTICULARPURPOSE.

Wemakeno otherwarranty,representation orguarantee,norisanyone authorized tomakeone on our

behalf. Weshall notbe liable forconsequential damage ofanykind,including loss ordamage resulting,

directlyorindirectly,from the useorloss ofuseofthe machine.Withoutlimiting the generality ofthe

foregoing,thisexclusion from liability embracesthe purchaser'sexpensesfordowntime,damagesfor

whichthe purchasermaybe liable tootherperson,damagestoproperty,and injuryordeathofany

persons.

Thiswarranty shall not be deemed tocovermaintenanceparts, including but not limited toblades, belts,

hoses,hydraulicoil,orfilters,forwhichweshall haveno responsability orliability whatsoever.

R

Other manuals for Workman 350 II

1

This manual suits for next models

1

Table of contents

Other IMER Mixer manuals

Popular Mixer manuals by other brands

Groen

Groen DHT-40 TA/3 quick start guide

Hamilton Beach

Hamilton Beach ALL-METAL DRINK MIXER user guide

Morphy Richards

Morphy Richards Latitude 48970 manual

Metcalfe

Metcalfe MP10 Installation & operating instructions

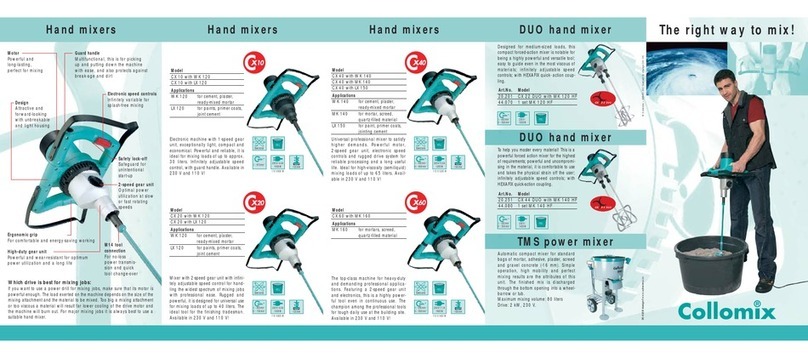

Collomix

Collomix DUO Hand Mixer quick guide

Varimixer

Varimixer V30K Spare part and operation manual