IMER MIX 60 PLUS User manual

INSTRUCTION MANUAL

IMER U.S.A. inc.

MORTAR MIXER MIX 60 PLUS

1193981 ( 115 V - 60 Hz )

Machine serial N°

Part. number 3233158 R02 - 2018/09

IMER U.S.A. Inc.

221 Westhampton Place

Capitol Heights, MD

20743

Ph / 800.275.5463

R

2

IMER U.S.A. Inc.

MIX 60 PLUS

Thank you for purchasing a mortar mixer MIX 60 PLUS from an IMER U.S.A. dealer.

Your decision is an intelligent one.

No other mixer in the world today offers the features and value of the MIX 60 PLUS.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have an idea

or thought to share with us regarding this Product we would appreciate hearing from you. Our motto is

"Tools and Services for the 21st Century". We look forward to delivering the goods.

Thank you again for your purchase,

* After the initial set-up the Mixer can be knocked down or reassembled in just minutes.

* Direct drive of the paddle, efcient and safe.

* Compact, the clever design allows the MIX 60 PLUS to t into the trunk or hatchback

area of almost all cars and trucks.

* Finish, the high quality of paint and construction components ensure a piece of equipment

that you will be proud to own for years.

Mace T. Coleman, Jr.

President, IMER U.S.A. Inc.

221 Westhampton Place

Capitol Heights, MD 20743

Ph / 800.275.5463

S/N:

3

IMER U.S.A. Inc.

MIX 60 PLUS

TABLE OF CONTENTS

TECHNICAL DATA .................................................................................................... page 4

DESIGN STANDARDS ............................................................................................. page 5

NOISE EMISSION LEVEL ....................................................................................... page 5

OPERATION SAFETY .............................................................................................. page 5

ELECTRICAL SAFETY ........................................................................................... page 5

ASSEMBLY .............................................................................................................. page 5

TRANSPORT ........................................................................................................... page 5

INSTALLATION........................................................................................................ page 5

ELECTRICAL CONNECTION....................................................................................page 5

START-UP .............................................................................................................. page 5

OPERATION............................................................................................................. page 5

APPLICATIONS ....................................................................................................... page 6

EMERGENCY STOP................................................................................................ page 6

CLEANING .............................................................................................................. page 6

MAINTENACE.......................................................................................................... page 6

TROUBLE-SHOOTING ........................................................................................... page 6

WIRING DIAGRAM ................................................................................................. page 7

SPARE PARTS ........................................................................................................page 8

WARRANTY ............................................................................................................page10

4

IMER U.S.A. Inc.

MIX 60 PLUS

TECHNICAL SPECIFICATIONS

Drum capacity gal (liter) 15 (56)

Drum diameter in (mm) 22.8" (580)

Paddle rpm RPM 55

Machine weight lbs (Kg) 67 (30)

Machine weight with packing lbs (Kg) 71 (32)

Packing dimensions in (mm) 24.4x23x17.9

(620x585x455)

)Wheel dimensions in (mm) Ø 3.9x0.8

(Ø100x20

Motor rating HP (Kw) 0.75 (0,55)

Paddle rotation direction clockwise

Absorbed current A 7

Voltage Volt 115

Frequency Hz 60

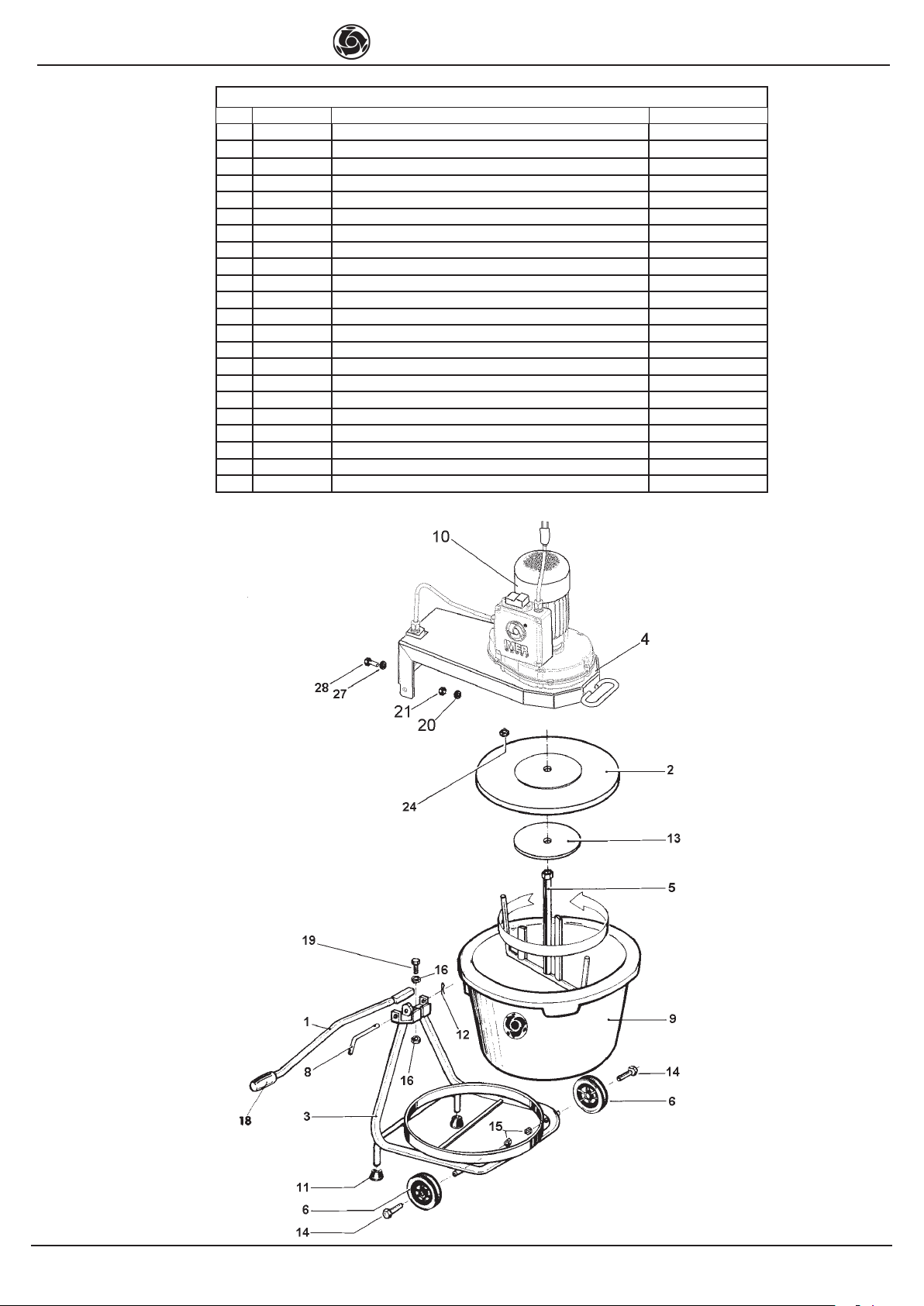

1 HANDLE

2 SAFETY GRID

3 FRAME

4 REDUCTION UNIT SUPPORT

5BLADE ASSEMBLY

6 TANK HOUSING

7 GEARMOTOR

8 LEGS

9 TANK

10 LIMIT SWITCH

11 DATA PLATE

12 TANK BRACKET

13 WHEEL

14 ELECTRICAL PANEL

Fig. 1

TECHNICAL DATA

5

IMER U.S.A. Inc.

MIX 60 PLUS

Dear Customer,

Congratulations on your choice of purchase: IMER mixers are uni-

versal machines for MIX series: the MIX series mixers are ideal for

mixing dry or wet ne particle material (gypsum, cement, ceramic

tile adhesives, plaster, epoxy resin or proprietary mixed products).

WORKING IN SAFETY

To work in complete safety, read the following instructions

carefully.

- This OPERATION AND MAINTENANCE manual must be kept

on site by the person in charge, e.g. the SITE FOREMAN, and

must always be available for consultation.

- The manual is to be considered integral part of the machine and

must be kept for future reference until the machine is disposed of.

If the manual is damaged or lost, a replacement may be requested

from the saw manufacturer.

- The manual contains important information regarding site pre-

paration, machine use, maintenance procedures, and requests

for spare parts. Nevertheless, the installer and the operator must

both have adequate experience and knowledge of the machine

prior to use.

- To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this manual

carefully, and observe all safety standards currently in force for

the prevention of accidents at work (use of safety footwear and

gloves in accordance with S.I. N°3073 of 30/11/92).

Pay special attention to warnings bearing the following symbol:

-

MAKE SURE THAT SIGNS ARE LEGIBLE.

- It is strictly forbidden to carry out any form of modi-

cation to the steel structure or working parts of the machine.

IMER INTERNATIONAL declines all responsibility for non-

compliance with laws and standards governing the use of this

equipment, in particular; improper use, defective power supply,

lack of maintenance, unauthorised modications, and partial or

total failure to observe the instructions contained in this manual.

1. DESIGN STANDARDS

The MIX 60 mixer has been designed and constructed in accor-

dance with the following standards:

I.E.C.34.4; EN 60204-1; EN

392 (91/368 CEE).

2. NOISE EMISSION LEVEL

Operator exposure to sound emission levels: the MIX 60 PLUS

mixer noise level during operation is measured at 65 dB(A).

3. OPERATION SAFETY

- The Imer MIX 60 PLUS cement mixer may only be used when

tted with all required safety devices which must be in perfect

working condition.

- Keep well clear of the mixing tank during operation.

- Never connect MIX 60 PLUS to defective power lines.

- Make electrical connections on the construction site where they

will not be subject to damage.

- Lay power cables where they are not subject to risk of damage

or penetration of water into connectors. Only use connectors

electrically protected against water sprays.

- Never connect the mixer to makeshift mains connections. If

necessary, consult qualied personnel.

- Repairs to electrical installations must only be carried out by

qualied technicians. Do not operate the mixer during mainte-

nance or repairs.

- Observe all accident prevention and safety standards in the

work area.

4. ELECTRICAL SAFETY

The IMER MIX 60 PLUS is designed in compliance with EN

60204-1 standards and features water spray protection (IP54)

and overload protection.

The mixer is also tted with a safety system comprising a limit

switch which shuts off machine operation whenever the reduction

unit support is lifted.

To reset, press the green pushbutton located in the electrical

cabinet.

5. ASSEMBLY

- Position the frame and handle as shown in g.2.

- Insert the link pin and the cotter pin and tighten.

- Insert the tank in the circular housing, ensuring that the four

handles t onto the steel brackets. to prevent tank rotation during

operation.

- Fit the safety grid, blade cover and screw the blade fully down

(g.3).

6. TRANSPORT

- Warning: Always unplug the mixer from the power

supply before handling.

- MIX 60 PLUS is easily transported; use the handle indicated in

g.4 for manual transport of the mixer.

- Never use the power cable to pull the machine.

- Never pull the power cable to unplug the machine.

7. INSTALLATION

- Remove the machine from the packaging.

- Install the mixer on level and solid ground

- Do not tilt the mixer during operation.

- When transporting the machine ensure that there are no obsta-

cles which may impair stability.

8. ELECTRICAL CONNECTION

- Ensure that mains voltage and cable sizes correspond to

specications.

- MIX 60 PLUS is tted with an ac motor which must be connected

to a 115 V power supply with a cable tted with suitable wear-

resistant, anti-crushing and weatherproof sheathing.

Cable length must not exceed 50 yards.

- MIX 60 PLUS must only be used when tted with all

required safety devices, which must be in perfect working

condition.

- Lay power cables where they are not subject to risk of

damage or penetration of water into the connectors.

- Only use connectors electrically protected against water

sprays. Do not stand the machine on the power cable.

- Never use the mixer with a makeshift power connection.

-The electrical connection must be carried out by a qua-

lied technician.

- Ensure that the cable is securely clamped inside the plug and socket.

- Observe all accident prevention and safety standards in

the work area.

- During mixer operation, do not insert tools or other objects in the tank

to avoid damage to the mixer or operator safety hazard.

9. START-UP

Press the green botton to start the mixer.

If the mixer blades do not rotate the overload cutout switch trips to

shut down the machine. Press “ON” to resume operation.

10. OPERATION

- Ensure that the power cable is tted with a residual current

circuit breaker upline of the machine.

- Make sure that all other persons keep clear of the mixer during

operation.

- Do not use the mixer in areas subject to the risk of re.

- Switch the mixer off before leaving it unattended.

- Make sure that the mixer is completely immobile before handling

or installation.

- Make sure that the mains voltage corresponds with the indications

on the mixer data plate.

- Make sure that the mixer blades rotate clockwise.

- Make sure that no clothing comes into contact with

mixing blades.

- Warning: Never start the mixer without the safety grid

tted; the cover is a safety device and must be tted to avoid

direct contact with the mixer blades.

6

IMER U.S.A. Inc.

MIX 60 PLUS

11. APPLICATIONS

11.1. ADHESIVES FOR CERAMIC TILES, FLOORING AND

WALL CLADDING

Pour in the quantity of water as required for the relative product,

considering that the maximum mixer capacity 100 lbs of adhesive.

Start the machine and during operation, pour the powder directly over

the plastic cover to obtain a smooth mixture.

- Warning: when mixing large quantities, pour the product

into the tank gradually.

11.1. PAINT

Pour in the required amount of paint and water.

- The use of acid, solvents, and other aggressive chemical

products is strictly prohibited.

11.1. CEMENT

Mix 60 can also mix mortar, cement, or lime provided that a ne

particle size is used.

- Warning: Avoid excessive stiffening of the mixture due to

the addition of too much cement, lime or other water absorbing

products.

12. EMERGENCY STOP

- In an emergency, press the green pushbutton and unplug

the mixer.

- The electric motor is protected from thermal overload; if

the motor overheats the mixer is shut down automatically. Allow

the motor to cool before resuming operation.

13. CLEANING

After each work shift and before prolonged periods of disuse, clean

the tank interior and exterior thoroughly.

- Always unplug the mixer from the mains before cleaning

(also when using brushes, cloths or scrapers etc.).

- Never operate the mixer during cleaning operations.

- When using water jets for cleaning, never direct the water at the

mixer drive unit.

14. MAINTENANCE

- Warning: Always switch off the mixer and unplug from the

power supply before carrying out maintenance.

- Repairs to the electrical installation must be carried out exclusively

by qualied personnel. Replacement parts must be original IMER

spare parts and must not be modied in any way.

The IMER MIX 60 PLUS is designed for minimum maintenance

requirements. However, we recommend changing the reduction unit

oil after 3000 hours continuous duty with SAE 40 oil.

Check that the socket/plug contacts are clean. If oxidised, clean

immediately.

- Used oil is considered a special waste product and must

be disposed of in accordance with the law.

- Always ensure that signs and warning notices on the

machine are clearly legible.

For any problem, see your dealer or call IMER U.S.A. @

800.275.5463.

15. TROUBLE-SHOOTING

PROBLEM CAUSE REMEDY

The motor does not

start when switched

on

No power on power cable Check power cables

Plug not inserted correctly

in socket

Ensure correct connection

Faulty power cable to

electrical panel

Change power cable

Loose wire in electrical

panel

Reconnect wire

Loose wire in motor

terminal board

Reconnect wire

Faulty main switch Replace switch

Residual current circuit

breaker tripped

Reset switch. If it does not

reset, refer to a qualied

electrician to check the

electrical system to ensure

complete safety.

The motor does not

stop when the safety

grid is lifted

Faulty limit switch Replace limit switch

Motor starts with

difculty

Mixture is too stiff Reduce mixture quantity or

dilute and try again.

Should the problem

persist

Contact IMER Technical Service @ 800.275.5463 or

your IMER Dealer

16.

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials

with silica in their composition my give off dut or mists cintainig crystalli-

ne silica. Silica is a basic component of sand, quartz, brick clay, granite

and numerous other minerals and rocks. Repeated and/or substantial

inhalation of airborne crystalline silica can cause serious or fatal respira-

tory diseases, including silicosis. In addition, California and some other

authorities have listed respirable crystallinesilica as a substance known

to cause cancer. Whwn cutting such materials, always follow respiratory

precautions.

Use appropriate NIOSH-approved respiratory protection where dust

hazard may occur. Paper masks or surgical masks without a NIOSH

approval number are not recommended because they do little to protect

the worker. For more information about respirator programs, including

what respirators have received NIOSH approval as safe and effective,

please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C:F.R. § 1910.134).

Visit http://www.osha.gov for more information.

California proposition 65 message

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contain chemicals know (to the State of Ca-

lifornia) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

-Lead, from lead-based paints

-Crystalline silica, from bricks and cement and other masonry products

-Arsenic and chromium, from chemically treated lumber

For further information , consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

http://www.P65warnings.ca.gov

Your risk from these exposures varies depending on how often you do

this typer of work. To reduce your exposure to these chemicals, work in

a well-ventilated area, and work with approved safety equipment, such

as dust masks that are specially designed to lter out microscopic par-

ticles. Where use of a dust extraction device is possible, it should be

used. To achieve a high level oof dust collection, use an industrial HEPA

vacuum cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103.

7

IMER U.S.A. Inc.

MIX 60 PLUS

WIRING DIAGRAM

Fig.4

Fig.3

Fig.2

S1 SWITCH

S2 LIMIT SWITCH

F1 MOTOR TEMPERATURE SENSOR

C1 CAPACITOR

PE EARTH WIRE

N NEUTRL WIRE

L1 PHASE WIRE

AM MOTOR RUN WINDING

AA MOTOR START-UP WINDING

L1

N

PE

C1

S2

U<

23

13

24

14

A1

115 V

60 Hz

S1

F1

AA

AM

M

1~

8

IMER U.S.A. Inc.

MIX 60 PLUS

SPARE PARTS

All orders for spare parts must include the following:

1) Type of machine. (Example: MIX 60 PLUS mixer)

2) Part number and drawing references of each part, see the parts list.

3) Serial number and year of manufacture recorded on the machine's identication plate.

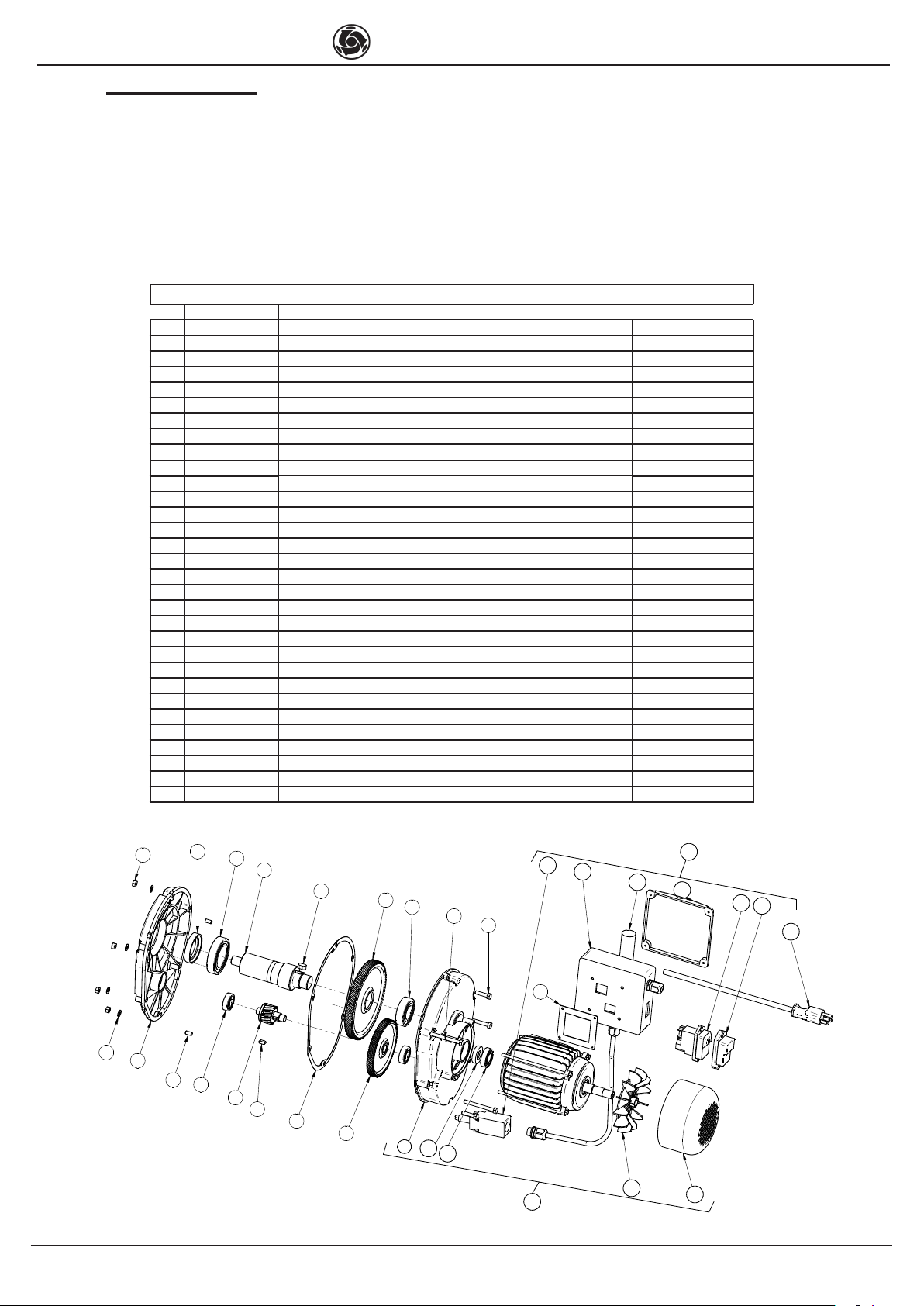

DIAGRAM #1 GEARMOTOR ASSEMBLY COD. 3233150

RIF. P. n. Description Note

1 3233104 GEARBOX CASE-HALF

2 2204420 BEARING 6201

3 3233054 PINION GEAR

4 3233061 GEAR

5 2204550 BEARING 6205

6 3233056 MAIN SHAFT

7 3233053 GEAR

8 2204504 BEARING 6008

9 2207405 OIL SEAL 55X40X10

10 3210482 GEARBOX GASKET

11 3210485 GEARBOX CASE-HALF

12 3210955 PLUG WITH CABLE

13 2229500 KEY 8X7X15

14 2229249 KEY 5X5X12

15 2228819 PIN Ø6X12

16 2222012 BOLT M6X60

17 2222010 BOLT M6X25

18 2224530 WASHER Ø6

19 2223260 NUT M6

20 3209214 GASKET

21 3200005 LIMIT SWITCH

22 3210904 FAN

23 3233097 FAN COVER

24 3209337 SWITCH

25 3233059 OIL SEAL 15x32x7

26 3208982 BEARING 6202

27 3210923 CAPACITOR MF. 50 250V

28 3233156 ELECTRIC PANEL

29 3233056 ELECTRICAL BOX

30 3233155 MOTOR+GEARBOX CASE-HALF 115V/60Hz

31 3209340 PROTECTION COVER

2

8

10

11

9

3

6

15

14

13

18

20

19

17

1

75

29

22 23

31

25 26

27

28

16

30

21

29

24

12

4

9

IMER U.S.A. Inc.

MIX 60 PLUS

DIAGRAM #2 MORTAR MIXER

RIF. P. n. Description Note

1 3205592 HANDLE

2 3205607 COVER

3 3206584 FRAME

4 3233048 SUPPORT

5 3205587 COMPLETE PADDLE

6 3205257 WHEEL

8 3205623 PIN

9 3210432 TANK

10 3233150 GEARMOTOR

11 3205926 PLUG

12 2226703 SPLIT PIN

13 3205611 STEEL DISK

14 2222154 BOLT M10X120

15 2223920 SELF LOCKING NUT M10

16 2223705 NUT M12

18 3206079 HANDLE

19 2222083 BOLT M12X70Z

20 2224950 WASHER Ø4

21 2223500 NUT M4

24 2223924 NUT A 6

27 2224535 WASHER

28 3204186 SCREW M4X40

10

IMER U.S.A. Inc.

MIX 60 PLUS

221 Westhampton Place

Capitol Heights, MD

20743

Ph / 800.275.5463

U.S.A. INC.

IMER

EQUIPMENT WARRANTY

R

IMERU.S.A. INC.

We warrant to the original purchaser that the IMER equipment described herein (the "equipment") shall

be free from defects in material and workmanship under normal use and service for which it was intended

for period of one (1) year from the date of purchase by the original purchaser.

Our obligation under this warranty is expressly limited to replacing or repairing, free of charge, F. O.B. our

designated service facility, such part of the equipment as our inspection shall disclose to be defective.

Parts such as engines, motors, pumps, valves, electric motors, etc. furnished by us, but not manufactured

by us, will carry only the warranty of the manufacturer. Transportation charges or duties shall be borne by

purchaser. This shall be the limit of our liability with respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged by reason of

accident, negligence, unreasonable use, faulty repairs, or which has not been maintained and operated in

accordance with our printed instructions for the equipment. Further, this warranty is void if the equipment,

or any of its components, is altered or modied in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRES-

SED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to make one on our

behalf. We shall not be liable for consequential damage of any kind, including loss or damage resulting,

directly or indirectly, from the use or loss of use of the machine. Without limiting the generality of the fore-

going, this exclusion from liability embraces the purchaser's expenses for downtime, damages for which

the purchaser may be liable to other person, damages to property, and injury or death of any persons.

This warranty shall not be deemed to cover maintenance parts, including but not limited to blades, belts,

hoses, hydraulic oil, or lters, for which we shall have no responsability or liability whatsoever.

HEADQUARTERS

Other manuals for MIX 60 PLUS

1

This manual suits for next models

3

Table of contents

Other IMER Mixer manuals