IMER SPIN 15 User manual

Machine serial N°

Part. number 3237384 R00 - 2019/07

IMER U.S.A. Inc.

221 Westhampton Place

Capitol Heights, MD

20743

Ph / 800.275.5463

CONTINOUS MIXER SPIN 15

1106340 (115V 60Hz)

2

IMER INTERNATIONAL S.p.A.

SPIN 15

Thank you for purchasing a machine from an IMER U.S.A. dealer.

Your decision is an intelligent one.

No other mixer in the world today oers the features and value of the our machne.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have an idea

or thought to share with us regarding this Product we would appreciate hearing from you. Our motto is

"Tools and Services for the 21st Century". We look forward to delivering the goods.

Thank you again for your purchase,

* After the initial set-up the Mixer can be knocked down or reassembled in just minutes.

* Compact, the clever design allows the machine

area of almost all cars and trucks.

* Finish, the high quality of paint and construction components ensure a piece of equipment

that you will be proud to own for years.

S/N:

3

IMER INTERNATIONAL S.p.A.

SPIN 15

Special attention must be given to warnings with this symbol:

ENGLISH

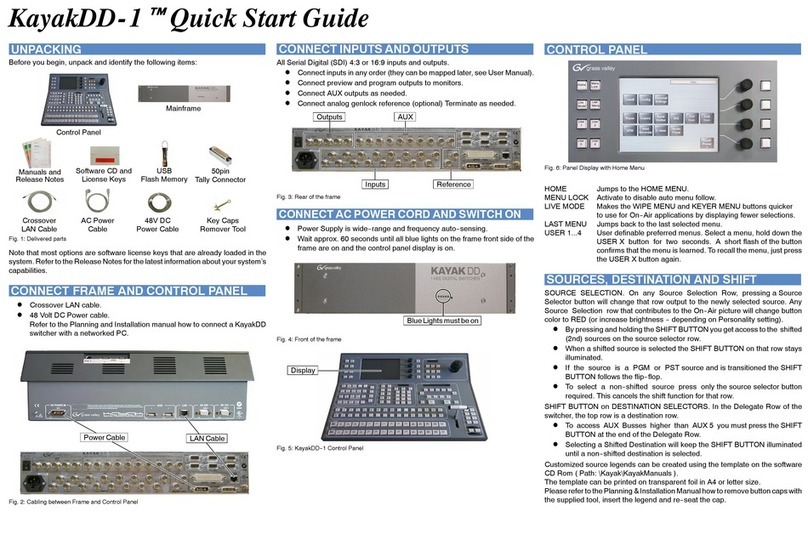

(1) WHEELED FRAME

(2) HOPPER

(3) MIXING CHAMBER

(4) MATERIAL OFFLOAD PORT

(5) ELECTRICAL PANEL

(6) AUGER TYPE BATCHING SYSTEM

(7) GEARMOTOR

(8) MIXER

(9) WATER CIRCUIT

(10) HOPPER GRID

(11)WATER PUMP

(12) I DUST GRID

(13) FLOW METER

(14) PUMP ELECTRICAL PANEL

FIG.1

1

2

5

10

3

4

12

13

7

11

9

14

A A

SEZIONE A-A

6

8

4

IMER INTERNATIONAL S.p.A.

SPIN 15

GB SPIN 15A

TECHNICAL DATA

Machine code 1106340 - 115V 60Hz

MAIN POWER SUPPLY V

Hz

115

60

WATER CONNECTION 1/2"

GEARMOTOR kW 1.4

WATER PUMP kW 0.45

MAXIMUM PRESSURE bar 2.0

MAXIMUM POWER kW 7.75

MATERIAL FLOW RATE

(APPROX.) l/min 15

DIMENSIONS

X

Y

Z

mm

mm

mm

1380

720

1165-1095-950

LOADING HEIGHT mm 1165-1095-950

HOPPER CAPACITY l 60

WEIGHT kg

78

kg

85

NOISE EMISSION LEVEL

LPA A 1M - LWA -

EN ISO 3744

(2000/14/EC)

dB(A) <76

88

5

IMER INTERNATIONAL S.p.A.

SPIN 15

The mixed material is then conveyed to the discharge outlet (ref.4),

ready to use and collected in crates, wheelbarrows, buckets etc.

and then applied manually where required.

4. OPERATION SAFETY

- Before using the mixer, ensure that it is tted with all

safety devices.

- Never insert parts of the body and/or tools in the hopper

or discharge outlet during operation.

- Always use the mixer in suciently ventilated envi-

ronments.

All current standards governing accident prevention and safety

devices must be observed in the workplace.

Take care when handling sacks of material to avoid dispersion of

dust with inhalation of the latter; if this is not possible, masks must

be worn to protect the mouth and nose.

- Never use the machine in areas subject to the risk of

explosion/res or in underground installations.

The mixer is not equipped with a lighting system and therefore the

The power lines must be laid to prevent any possible damage.

Never place the mixer on electric power cables.

Ensure that the electrical connection is protected against the risk

of water penetration in connectors. Use exclusively connectors

and couplings equipped with water spray protection.

- Never use inadequate or provisional electric lines: if in doubt

consult specialist personnel for assistance.

- Repairs to the electrical circuit must be performed exclusively by

specialised personnel. Disconnect the machine from the power

supply before performing maintenance or repairs.

-Avoid contact of electric wires with movable and/or moving parts

of the machine. to avoid injury from contact with live metal parts.

-CAUTION!

Keep the hands away from the outlet.

5. ELECTRIC SAFETY

The SPIN15 mixer is constructed according to standard EN 60204-1,

with protection against water sprays and protection against overload

and power failure.

The mixer must be connected to the earthing circuit.

To facilitate transport, the machine can be disassembled as

Dear Customer,

compliments on your purchase: this IMER mixer, the result of

long-standing experience in the eld, features maximum reliability

and innovative technical solutions.

- WORKING IN SAFETY.

To ensure complete safety, read all the instructions in this

manual carefully.

This OPERATION AND MAINTENANCE manual must be kept

by the Site Manager and be always available for consultation.

The manual is considered part of the machine and must be stored

for future reference ( EN ISO 12100 ) through to scrapping of the

machine itself. If the manual is lost or damaged, a replacement

copy can be ordered from the manufacturer.

The manual contains important information on construction site

procedures, installation, operation, maintenance and requests

for spare parts. Nevertheless, the user must both have adequate

experience and knowledge of the machine prior to use: the user

should be trained by a person totally familiar with the operation

and use of this machine.

To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this manual

carefully, and observe all safety standards currently in force for

the prevention of accidents at work (use of safety footwear and

suitable clothing, helmets, gloves, goggles etc.).

- Make sure that all signs are legible.

- It is strictly forbidden to carry out any form of modi-

cation to the steel structure or working parts of the mixer.

IMER INTERNATIONAL accepts no responsibility in the event of

damage or defects on machinery or equipment not supplied by

IMER and used in combination with IMER machinery.

IMER INTERNATIONAL accepts no responsibility in the event

of failure to comply with laws governing the use of this type of

equipment, with particular reference to: improper use, incorrect

failure to comply, either wholly or partially, with the instructions

set out in this manual.

IMER INTERNATIONAL reserves the right to modify the cha-

racteristics of the mixer and/or contents of this manual, without

the obligation to update the previous machine and/or manuals.

1. TECHNICAL DATA

2. NOISE EMISSION LEVEL

Table 1 shows the sound pressure levels of the mixer measured

at the ear of the operator (LpA at 1 m) and noise emission levels

in the environment (power LWA) measured according to EN ISO

3744 (2000/14/CE)

3. DESCRIPTION OF MIXER OPERATION

- THE CONTINUOUS HORIZONTAL MIXER is designed

for use in building sites, for mixing and pumping all mixed

mortars declared as compatible with this type of machine by

the material manufacturers: brickwork plasters, mortars for

semi-dry tiles, cement mixes, lime/cement based plasters,

grouting mortar etc

3.1 DESCRIPTION OF MIXER (see g.1)

The mixer comprises a wheeled frame (ref.1), which supports a

hopper (ref.2), a mixing chamber (ref.3), a water circuit (ref.9), an

electrical panel (ref.5).

There is a version of horizontal mixer with the water pump already

assembled (ref. 11).

The pre-mixed dry material is poured in to the hopper (using sacks

or by means of other equipment), which houses an auger batching

system (ref.6), activated by a gearmotor (rif.7), which moves the

auger, transferring the material into the mixing chamber. This

mixes the material with water delivered directly to the chamber by

the water pump and via the water circuit.

TRANSALTED INSTRUCTIONS

6. MECHANICAL SAFETY (see g.1)

The hazardous points on the IMER mixer are protected by means

kept in perfect condition. For example, this includes the electric

motor cooling fan guard and the hopper grid (ref. 10) to prevent

contact with the auger.

Also, release of the mixing chamber, shuts down all rotary parts

7. TRANSPORT (see g.2 and g.3)

- CAUTION! Before moving the mixer, always detach

the power plug.

Before moving the mixer, disconnect the water supply hose.

Only a minimal amount of the material should be in the hopper

when handling.

Lift the mixer by means of the relative handles (g.2) and

push in the required direction.

6

IMER INTERNATIONAL S.p.A.

SPIN 15

8. INSTALLATION

-

ronment where it does not constitute an obstruction either during

use or cleaning at the end of the work shift.

the material outlet.

9. CONNECTIONS

9.1 ELECTRICAL CONNECTION (see g.5)

- Ensure that the power supply voltage, mains frequency

and electrical connection (socket, fuses, cable) correspond

to specications in table 1.

current overload (e.g. by means of fuses or a thermal magnetic

cut-out) and against dispersion current to earth (e.g. with a dif-

ferential circuit breaker). The electric cable wire size must take

into account the operating currents and length of the line to avoid

excessive voltage drops.

Avoid use of extension leads wound on drums. The power cable

must be suitable for frequent movements and with an abrasion

resistant sheath

(e.g. type H07RN-F).

Before connecting the mixer to the electrical mains, ensure that all

particular that the hopper grid is secured in place, that the exten-

sion in good condition and that the plugs and sockets are not wet.

Connect the mixer socket on the electrical panel to the mains

-CAUTION! Before lifting the mixer, always check that all ma-

chine components are correctly secured and tted in place

and no objects have been left on the surface

- CAUTION! Lift with care to avoid hazardous oscillations

- CAUTION! Never use points other than as specied in gure

3 to lift the machine

9.2 WATER CONNECTION (see g. 1)

Connect the water hose (table 1) to the water mains.

With horizontal mixer without water pump, the wa-

ter mains must guarantee a minimum flow rate of

20 l/min and a minimum pressure of 2 bar.

-perform air purge through appropriate valve before each start

-With a water pump mixer if the pump is not fed by water, the

sealing gasket burns

- the maximum water pressure must not exceed 5 bar

10. LOADING HEIGHTS (SEE FIG 6):

T

heights.

The feet can slide within the frame before being locked in position

heights:

1) Direct loading of material into SMALL50 type plaster mixer;

2) Direct loading of material onto trolley;

3) Direct loading of materials into work bucket.

7

IMER INTERNATIONAL S.p.A.

SPIN 15

FIG. 6

11. START-UP

- During work start and stop the mixer exclusively by

means of the ON/OFF buttons.

- Load the pre-mixed dry material. Take the bags of material and

two end corners of the bag to completely empty the contents into

- At this point position a suitable container below the material

outlet and start up the mixer by means of the ON/OFF switch.

The machine should now be in operation

To obtain the required material consistency:

Optimise the quantity of the water delivered by means of the valve,

while the mixer is in operation.

Make small adjustments of approx. 1/2 turn, every 15 seconds.

occurs, press the ON button to resume operation.

To stop the machine in the event of an emergency, press the red

button (OFF); all moving parts are shut down. Then disconnect

the plug from the power mains.

THERMAL CUTOUT PROTECTION:

- The electric motor is protected against overload by a

thermal cutout, the activation of which is indicated by total

shutdown of the machine. In this case, authorised personnel

should wait for the motors to cool and restart the unit by

means of the ON/OFF switch.

12. OPERATION

- The hopper safety grid must always be tted.

(ref. 2) in the grille support (ref. 1) to which the grille is attached.

The screw (ref. 2) is held captive by the stop ring (ref. 3), so the

grille support (ref.1) remains permanently attached to the grille

structure.

- Wear envisaged personal protection devices before

starting work.

12.1 Pauses during work

Interruptions exceeding 30 min should be avoided.

Prolonged shutdown can cause clogging in the mixing chamber

If no material exits the discharge outlet, this must be cleaned.

restart the unit.

13. MIXER CLEANING AND SHUTDOWN (see g. 4)

ON/OFF switch.

Remove the mixing chamber (ref.1) by turning it to release the

relative hooks (ref.2), together with the shaft (ref.3).

Empty and clean the mixing chamber and mixer with water and

dry both with paper.

the mixing chamber and hook up correctly.

switch, disconnect the power plug, close the water delivery valve,

open the auxiliary valve and detach the delivery hose.

Before restarting the machine, ensure that all valves are closed

again.

If the machine is not to be used for several days, empty the hopper

completely.

- Caution! Before disassembling the mixer or removing

the grid, ensure that the main switch is set to OFF and the

plug is disconnected from the power supply.

14. MAINTENANCE (see g. 1)

- Maintenance must be performed by adequately trained

personnel, after switching o the machine, disconnecting it

from the power supply and emptying the hopper.

Check daily that the water lter (table 2, ref.14) is clean.

Check weekly that the mixer shaft (ref. 8) is in good condition and

replace if necessary

Check weekly that the electric motors are free of dust and dirt and

if necessary clean using compressed air.

Check weekly that the plug and socket contacts are clean, dry

and rust free.

Every six months arrange for an inspection of the machine by an

authorised IMER service centre. -

Spent oil is a special waste.

Therefore it must be disposed of according to current legislation.

-

Always keep notices and symbols on the machine legible

8

IMER INTERNATIONAL S.p.A.

SPIN 15

PROBLEMS

CAUSES

CORRECTIVE ACTION

Machine does not start Electric current

-

No current delivered to connector of site panel (fuses?)

- No power delivered to machine

(defective connector connection? loose cable?)

- Main ON/OFF (thermal cutout) switch not turned on

- Main switch/inverter (3-PHASE version only) set to position 0

- Mixing chamber open

(thermal magnetic switch does not engage)

- Emergency pushbutton pressed (release)

- Check points listed alongside

Thermal cutout trips on

start-up

Material in hopper

- Material has hardened in the hopper

- The type of material requires more water for mixing

- Completely empty the hopper and restart with new material

- Increase the quantity of water delivered

Material consistency not

constant; too hard or too

fluid

Water supply insufficient

- Water hose bent

- Pump inlet water filter clogged

- Pressure reducer water filter clogged

- Pressure reducer faulty

- Check points listed alongside

The water continues to exit

from the mixing chamber

when machine is

stationary

Solenoid valve faulty - Contact an authorised IMER service centre

Material does not exit the

offload port

Mixing chamber clogged

- The container used for offload is too high and does not enable

the material to flow out

- The offload port is clogged

- Check points listed alongside

Mix not optimal The type of material used is not suitable

- Not all products on the market can be mixed with this type of high

speed mixing system

- Mixing shaft worn

- Consult the material manufacturers to check compatibility

- Replace shaft

INDICATOR LIGHT

ON

OFF

15 SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials

-

ne silica. Silica is a basic component of sand, quartz, brick clay, granite

and numerous other minerals and rocks. Repeated and/or substantial

inhalation of airborne crystalline silica can cause serious or fatal respira-

tory diseases, including silicosis. In addition, California and some other

authorities have listed respirable crystallinesilica as a substance known

to cause cancer. Whwn cutting such materials, always follow respiratory

precautions.

Use appropriate NIOSH-approved respiratory protection where dust ha-

zard may occur. Paper masks or surgical masks without a NIOSH appro-

val number are not recommended because they do little to protect the

worker. For more information about respirator programs, including what

visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C:F.R. § 1910.134).

Visit http://www.osha.gov for more information.

Your risk from these exposures varies depending on how often you do

this typer of work. To reduce your exposure to these chemicals, work

in a well-ventilated area, and work with approved safety equipment,

particles. Where use of a dust extraction device is possible, it should be

used. To achieve a high level oof dust collection, use an industrial HEPA

vacuum cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103

16.SCRAPPING

The machine must be disposed of according to the current

regulations.

The barred bin symbol indicates that at the end of its service life

the product must be scrapped separately from other materials.

The manufacturer is responsible for separate scrapping of the

equipment at the end of its service life. The user must therefore

contact the manufacturer and follow the instructions given by

the latter for separate scrapping of the equipment at the end of

its service life.

Separate scrapping for subsequent recycling, treatment and

for the environment and for the health of persons, and promotes

the reuse/recycling of the materials of which the equipment is

fabricated.

Incorrect/illegal scrapping is punishable by law.

California proposition 65 message

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contain chemicals know (to the State of

California) to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

-Lead, from lead-based paints

-Crystalline silica, from bricks and cement and other masonry products

-Arsenic and chromium, from chemically treated lumber

For further information , consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

http://www.P65warnings.ca.gov

9

IMER INTERNATIONAL S.p.A.

SPIN 15

WIRING DIAGRAM -

T1 - TRANSFORMER 25 VA 0-115-230/0-24V 50/60HZ

F1 - PRIMARY FUSE 6.3X32 2A

F2 - SECONDARY FUSE 6.3X32 2A

EM - EMERGENCY STOP

RT1 -AUTOMATIC SWITCH

E1 - WATER ELECTROVALVE 24vca 50/60 hz

M1 - MOTOR MIXER

FCS - SAFETY SWITCH

L1 - CONTRO LIGHT 24 VCA

C1 - RUN CAPACITOR 110mF 250V

C2 - START CAPACITOR 100 mF 250V

DSG - CIRCUIT BREAKER

10

IMER INTERNATIONAL S.p.A.

SPIN 15

F1 - FUSE 6.3 X32 2 A

KM - CONTACTOR 12A

RT2 - SWITCH 10 A

M2 - WATER PUMP MOTOR

WIRING DIAGRAM WATER PUMP 1107638

11

IMER INTERNATIONAL S.p.A.

SPIN 15

SPARE PARTS

12

IMER INTERNATIONAL S.p.A.

SPIN 15

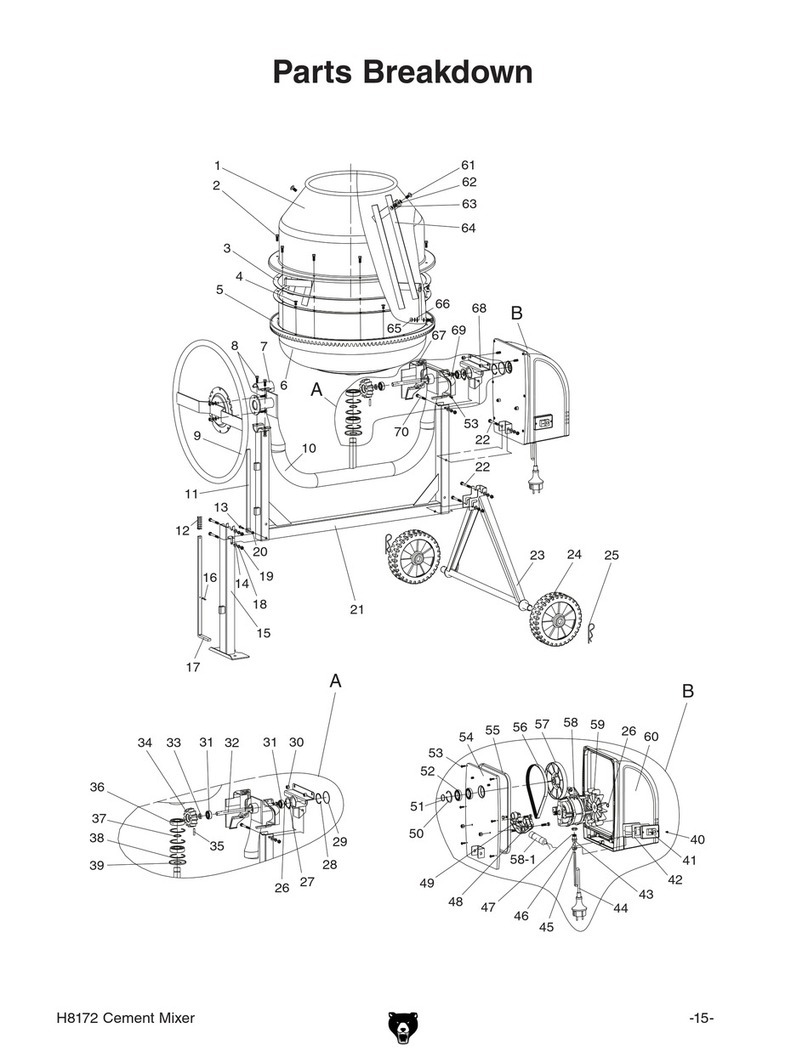

Fig.1 tav 1

14

3

13

1

24

5

11

12

910

8

6

7

19

20

18

16

16

17 17

15

14

21

Fig.1 Tav.1

13

IMER INTERNATIONAL S.p.A.

SPIN 15

TAV.1 STRUTTURA MACCHINA - STRUCTURE DE LA MACHINE - MACHINE STRUCTURE - MASCHINESTRUKTUR -

ESTRUCTURA DE LA MAQUINA

Rif. Cod. I F GB D E NOTE

13226550 TELAIO CHÂSSIS FRAME RAHMEN BASTIDOR

23226555 RINFORZO PER

MOTORIDUTTORE

RENFORCEMENT

MOTOREDUCTEUR

ENHANCEMENT FOR

GEARMOTOR

BESCHLAG GETRIEBE-

MOTOR

CONSOLIDACION

POR

MOTOREDUCTOR

33224231 FLANGIA GUARNIZIONE BRIDE JOINT SEAL FLANGE DICHTUNGSFLANSCH BRIDA DE LA JUNTA

43226558 GUARNIZIONE JOINT SEAL DICHTUNG GUARNICIÓN DI43

53237350 MOTORIDUTTORE MOTORÉDUCTEUR GEARMOTOR GETRIEBEMOTOR MOTORREDUCTOR 115V-60HZ

6.A 3226707 COCLEA VIS SANS FIN AUGER SCHNECKE TORNILLO SIN FIN

73226708 BOCCOLA CAMERA DI

MISCELAZIONE

DOUILLE CHAMBRE

MALAXAGE

MIXING CHAMBER

BUSHING MISCHKAMMERBUCHSE CASQUILLO CAMARA

DE MEZCLADO

83226706 ALBERO DI

MISCELAZIONE ARBRE MALAXAGE MIXING SHAFT MISCHERWELLE MEZCLADOR

93226560 GAMBAANTERIORE PIED AVANT FRONT FOOT VORDERER STELLFUSS PIE DELANTERO

10 3226561 GAMBA POSTERIORE PIED ARRIERE REAR FOOT HINTERER STELLFUSS PIE TRASERO

11 3237341 IMPIANTO ELETTRICO ELECTRIQUE GROUPE ELECTRIC UNIT ELEKTRISH BAUGRUPPE GRUPO ELECTRICO

12 3237349 IMPIANTO ACQUA CIRCUIT D’EAU WATER CIRCUIT WASSERANLAGE INSTALACIÓN DEL

AGUA

13 3226549 RETE GRILLE MESH NETZ REJILLA

14 3209809 RUOTA ROUE WHEEL RAD RUEDA SEMIPN.

200X50f26.5 MOZZ

15 3214791 FINECORSA FIN DE COURSE LIMIT SWITCH ENDSCHLALTER TOPR DE

RECORRIDO

16 2226700 COPIGLIA GOUPILLE PIN SPLIT SPLINT PASADOR

17 3223903 COPIGLIA GOUPILLE PIN SPLIT SPLINT PASADOR

18 3226551 CAMERA DI

MISCELAZIONE CHAMBRE MALAXAGE MIXING CHAMBER MISCKAMMER CAMARA DE

MEZCLADO

19 3224203 ATTACCO RAPIDO RAPID COUPLEUR QUICK COUPLEUR SHNELLKUPPLING CONNEXION RAPIDA M 1/2" OTTONE

20 3226559 SUPPORTO ANTERIAORE

MISCELATORE

SUPPORT ARRIERE

MELANGEUR

FRONT SUPPORT

MIXER

VORDERER HALTERUNG

MISHER

SOPORTE DELANTE-

RO MEZCLADOR

21A 3227714 TUBO ACQUA TUYAU EAU WATER HOSE WASSESCHLAUSS TUBO DE AGUA 1/2" 10BAR L.10MT

21B 3223706 TUBO ACQUA TUYAU EAU WATER HOSE WASSESCHLAUSS TUBO DE AGUA 1/2" 10BAR L.40MT

22 3236962 BLOCCAGGIO GRIGLIA SERRUE DE LA GRILLE MESH LOCK GRILLSCHLOSS BLOQUEO DE

PARILLA

23 3230084 FISSATORE ELASTICO FIXATOR ELASTIQUE ELASTIC FIXATOR ELASTICHER FIXATOR FIXATOR ELASTICO

24 3230236 VITE VIS SCREW SCHRAUBE TORNILLO TEFR 8X25 Z

14

IMER INTERNATIONAL S.p.A.

SPIN 15

TAV.2 3237349 IMPIANTO ACQUA -

CIRCUIT D’EAU

-

WATER CIRCUIT

-

WASSERANLAGE

-

INSTALACIÓN DEL AGUA

Rif. Cod. I F GB D E NOTE

13223631 ELETTROVALVOLA ÉLECTROVANNE SOLENOID VALVE MAGNETVENTIL ELECTROVÁLVULA 1/2" 115V

50/60HZ

23223627 VALVOLAANGOLO SOUPAPE ANGULAIRE ANGLE VALVE WINKELVENTIL VÁLVULA ÁNGULO 1/2"

33223607 NIPLES NIPLES NIPPLE NIPPEL NIPLE 1/2” OTTONE

43224381 TRONCHETTO TRICOISES BRANCH BOLZEN MANGUITO 1/2” L.50mm

53224203 ATTACCO RAPIDO FIXATION RAPIDE QUICK CONNECTOR SCHNELLAN-

SCHLUSS

CONNECTION

RAPIDA 1/2” M.

63228211 RIDUTTORE DI

PRESSIONE

RÉDUCTEUR DE

PRESSION PRESSURE REDUCER DRUCKMINDERER REDUCTOR DE

PRESIÓN

73227947 GOMITO COUDE ELBOW FITTING KURVE CODO 90° M.M. 1/2”

GHISA Z

83226677 COLLARE COLLIER CLIP SCHELLE ABRAZADERA 1/2”

93224608 TUBO ACQUA TUYAU EAU WATER HOSE WASSERSCHLAUCH MANGUERA AGUA D.13X20 20BAR

10 3224580 PORTAGOMMA PORTE-CAOUTCHOUC HOSE FITTING SCHLAUCHHALTER ADAPTADOR 90° 1/2” F. D.13

11 3223638 FASCETTA AD

ANELLO

COLLIER EN FORME

DE

BAGUE

RING CLIP RINGSCHELLE ABRAZADERA DE

ANILLO D. 20-23

12 3223697 GUARNIZIONE AT-

TACCO RAPIDO

JOINT DE RACCORD

EXCENTRIQUE

QUICK COUPLING

GASKET

DICHTUNG

SCHNELLKUPPLER

JUNTA CONEXIÓN

RÁPIDA

13 2222004 VITE VIS SCREW SCHRAUBE TORNILLO TE 5739

M8X35 Z.

14 2223570 DADO ECROU NUT MUTTER TUERCA M8

15 2224140 DADO ECROU NUT MUTTER TUERCA 1/8” M.

16 3223639 FILTRO FILTRE FILTER FILTER FILTRO

17 3227840 FILTRO FILTRE FILTER FILTER FILTRO "Y" 1/2" 200

MICRON

18 3225605 NIPLES RIDOTTO NIPLES REDUIT REDUCED NIPPLE NIPPEL REDUZIER-

STÜCK NIPLE REDUCIDO 3/4” -1/2”

19 3223636 ATTACCO RAPIDO FIXATION RAPIDE QUICK CONNECTOR SCHNELLAN-

SCHLUSS

CONNECTION

RAPIDA 3/4” F.

20 3227182 MANOMETRO MANOMÈTRE GAUGE MANOMETER MANÓMETRO D.63 0-10 BAR

1/4”M.

15

IMER INTERNATIONAL S.p.A.

SPIN 15

TAV. 3 MOTORIDUTTORE - MOTORÉDUCTEUR - GEAR MOTOR - GETRIEBEMOTOR - MOTOREDUCTOR

SPIN15-SPIN 15A 115V - 60HZ cod. 3237350

RIF. COD. I F GB D E NOTE

1 2201130 PIGNONE PIGNON PINION RITZEL PIÑÓN

2 2204220 CUSCINETTO ROULEMENT BEARING LAGER COJINETE 6206

3 2204440 CUSCINETTO ROULEMENT BEARING LAGER COJINETE 6004 2RS

4 2204550 CUSCINETTO ROULEMENT BEARING LAGER COJINETE 6205 SKF

5 2207490 ANELLO PARAOLIO PARE-HUILE OIL SEAL ÖLDICHTUNG GUARDAGOTAS 62X30X10

6 2216331 GUARNIZIONE JOINT GASKET DICHTUNG JUNTA 6204

7 2222509 VITE VIS BOLT SCHRAUBE TORNILLO 5931 M8X20 Z

8 2222513 VITE VIS BOLT SCHRAUBE TORNILLO 5931 M8X30 Z

9 2222514 VITE VIS BOLT SCHRAUBE TORNILLO 5931 M8X40 Z

10 2227340 ANELLO ARRESTO BAGUE D'ARRET STOP RING SPERRING ANILLO DE TOPE D 30

11 2227660 ANELLO ARRESTO BAGUE D'ARRET STOP RING SPERRING ANILLO DE TOPE D 62

12 2228820 SPINA PIVOT PIN ZAPFEN PERNO D.2X14

13 2229327 LINGUETTA LANGUETTE KEY FEDER LENGÜETA 6X6X400

14 2229450 LINGUETTA LANGUETTE KEY FEDER LENGÜETA 8X7X20

15 2235420 LIVELLO OLIO NIVEAU HUILLE OIL LEVEL PLUG SCHAUGLAS NIVEL ACEITE

16 2237301 DISTANZIALE ENTRETOISE SPACER BRACKET DISTANZHULSE ESPACIADOR 20X2

17 3234948 INGRANAGGIO ENGRENAGE GEAR ZAHNRAD ENGRANAJE Z.76 M.1.75

18 3225254 FLANGIA RIDUTTORE BRIDE REDUCTEUR REDUCTION REAR

FLANGE FLANSCH BRIDA DEL REDUCTOR

19 3226623 ALBERO ARBRE SHAFT WELLE EJE EIXO

20 3237342 MOTORE ELETTRICO MOTEUR ELECTRIC MOTOR KOMPLETTER

MUTTER MOTOR ELECTRICO

21 3226630 DISTANZIALE ENTRETOISE SPACER BRACKET DISTANZHULSE ESPACIADOR 35X31X14.5

22 3226631 ANELLO BAGUE RING RING ANILLO 25X30X38.5

23 3229751 INGRANAGGIO ENGRENAGE GEAR ZAHNRAD ENGRANAJE Z.59 M.2

24 3229749 INGRANAGGIO ENGRENAGE GEAR ZAHNRAD ENGRANAJE Z.43 M.2

25 3210707 CONDENSATORE CONDENSATEUR CAPACITOR KONDENSATOR CONDENSADOR 110mF 250V

26 3230847 SCATOLA ELETTRICA +

COPERCHIO

CAISSE ELECTRIQUE

+ COUVERCLE

ELECTRICAL BOX +

COVER

ELEKTRISCH

BOX+DECKEL

CAJON ELECTRICO

+ TAPA

16

IMER INTERNATIONAL S.p.A.

SPIN 15

TAV. 4

IMPIANTO ELETTRICO-ELECTRIQUE GROUPE-ELECTRIC-ELEKTRISH HAUGRUPPE-GRUPO ELECTRICO

SPIN 15 115V-60HZ COD.3237341

RIF. COD. I F GB D E NOTE

1 3237398 SCATOLA ELETTRICA +

COPERCHIO

CAISSE ELECTRIQUE

+ COUVERCLE

ELECTRICAL BOX +

COVER

ELEKTRISCH

BOX+DECKEL

CAJON ELECTRICO

+ TAPA

2 3226345 INTERRUTTORE

PRINCIPALE

INTERRUPTEUR SWITCH SCHALTER INTERRUPTOR

3 3225237

INTERRUTTORE INTERRUPTEUR SWITCH SCHALTER INTERRUPTOR

4 3225241 LED LED CABLE CLAMP KABELKLEMME PRENSACABLE

5 3201217 PRESSACAVO SERRE-CABLE CABLE CLAMP KABELKLEMME PRENSACABLE

6 3201216 PRESSACAVO SERRE-CABLE CABLE CLAMP KABELKLEMME PRENSACABLE

7 3211826 PRESSACAVO SERRE-CABLE CABLE CLAMP KABELKLEMME PRENSACABLE

8 2222022 VITE VIS BOLT SCHRAUBE TORNILLO

9 2224530

RONDELLA RONDELLE WASHER ANTERLEGSCHEIBE ARANDELA

10 2223260

DADO ECROU NUT MUTTER TUERCA

11 3227742

PORTAFUSIBILE FUSE BOX FUSE BOX FUSE BOX FUSE BOX

12 3227783

FUSIBILE FUSE FUSE FUSE FUSE

13 3225223

PROTEZIONE

INTERRUTTORE

PROTECTION

INTERRUPTEUR

SWITCH

PROTECTION SCUTZ SCHALTER PROTECCION

INTERRUPTOR

17 3214791

FINECORSA SWITCH SWITCH SWITCH SWITCH

18 3226204 CONNETTORE

ELETTROVALVOLA

ELECTROVALVE

CONNECTOR

ELECTROVALVE

CONNECTOR

ELECTROVALVE

CONNECTOR

ELECTROVALVE

CONNECTOR

19 3226210 BOBINA

REEL REEL REEL REEL

20 3200185 TRASFORMATORE TRANSOFORMATEUR TRANSOFORMER TRANSOFORMER TRANSOFORMER

21 3204782 SPINA PLUG PLUG PLUG PLUG

22 3237396 CONNETTORE HARTIG HARTIG PLUG HARTIG PLUG HARTIG PLUG HARTIG PLUG

8

9

10

20

6

5

22

7

17

13

3

4

18

19

2

11

12

23

1

17

IMER INTERNATIONAL S.p.A.

SPIN 15

4

3

2

5

1

2

2

TAV. 4-1

IMPIANTO ELETTRICO POMPA-ELECTRIC PUMP-SPIN 15 115V-60HZ COD.3237344

RIF. COD. I F GB D E NOTE

1 3237383 SCATOLA ELETTRICA +

COPERCHIO

CAISSE ELECTRIQUE

+ COUVERCLE

ELECTRICAL BOX +

COVER

ELEKTRISCH

BOX+DECKEL

CAJON ELECTRICO

+ TAPA

2 3209692 PRESSACAVO SERRE-CABLE CABLE CLAMP KABELKLEMME PRENSACABLE

3 3207929

BOX INTERRUTTORE BOX INTERRUPTEUR BOX SWITCH BOX SCHALTER BOX INTERRUPTOR

4 3207920

INTERRUTTORE INTERRUPTEUR SWITCH SCHALTER INTERRUPTOR

5 3237382 BOBINA

REEL REEL REEL REEL

18

IMER INTERNATIONAL S.p.A.

SPIN 15

POMPA ACQUA - POMPE - WATER PUMP - PUMPE - BOMBA

SPIN 15-A

1107638

KIT POMPA ACQUA - POMPE - KIT WATER PUMP - PUMPE - BOMBA

19

IMER INTERNATIONAL S.p.A.

SPIN 15

TAV. 6: POMPA ACQUA - POMPE - WATER PUMP - PUMPE - BOMBA

Rif. Cod. I F GB D E NOTE

13227387 LAMIERA SUPPORTO

POMPA TOLE DE SUPPORT

SUPPORT PLATE HALTERUNGSBLECH CHAPA DE SOPORTE

23237343 POMPA POMPE PUMP PUMPE BOMBA 115v 60Hz

33227431 COLLARE ZINCATO COLLIER CLIP SCHELLE ABRAZADERA M6 DI 35 H61

43223722 ATTACCO RAPIDO FIXATION RAPIDE QUICK CONNECTOR SCHNELLANSCHLUSS EMPALME RÁPIDO 1” M OTTONE

53227388 KIT CABLAGGIO POMPA

ACQUA KIT CABLAGE POMPE PUMP WIRING KIT KIT VERDRAHTUNG

PUMPE KIT CABLEADO BOMBA

63223639 FILTRO FILTRE FILTER FILTER FILTRO

73224349 NIPLES RIDOTTO NIPLES REDUIT REDUCED NIPPLE NIPPEL REDUZIER-

STÜCK NIPLE REDUCIDO 1” - 1/2”

83224580 PORTAGOMMA PORTE-CAOUTCHOUC HOSE FITTING SCHLAUCHHALTER ADAPTADOR 90° 1/2"F. D13

93224608 TUBO AIR WATER TUYAU EAU WATER HOSE WASSERSCHLAUCH TUBO DE AGUA

10 3223615 ATTACCO RAPIDO CON

PORTAGOMMA FIXATION RAPIDE QUICK CONNECTOR SCHNELLANSCHLUSS EMPALME RÁPIDO D13 OTTONE

11 3223638 FASCETTAAD ANELLO COLLIER EN FORME DE

BAGUE RING CLIP RINGSCHELLE ABRAZADERA DE

ANILLO D. 20-23

12 3225073 FASCETTAAD ANELLO COLLIER EN FORME DE

BAGUE RING CLIP RINGSCHELLE ABRAZADERA DE

ANILLO D. 17-20

13 3223697 GUARNIZIONE ATTACCO

RAPIDO

JOINT DE RACCORD

EXCENTRIQUE

QUICK COUPLING

GASKET

DICHTUNG

SCHNELLKUPPLER

JUNTA CONEXIÓN

RÁPIDA

14 2224204 RONDELLA RONDELLE WASHER ANTERLEGSCHEIBE ARANDELA M8X24Z

15 2224060 ROSETTA GROWER RONDELLE GROWER GROWER WASHER GROWER-UNTER-

LEGSCHEIBE ARANDELA GROWER D8 Z

16 2224530 RONDELLA RONDELLE WASHER ANTERLEGSCHEIBE ARANDELA M6X12Z S1.6

17 2223280 DADO ECROU NUT MUTTER TUERCA M6Z

18 2222076 VITE VIS SCREW SCHRAUBE TORNILLO TE 5739

M8X24 Z.

20

IMER INTERNATIONAL S.p.A.

SPIN 15

1107601

KIT FLUSSIMETRO - KIT FLUXMETRE - KIT FLOW METER

KIT DURCHFLUSSMESSER - KIT CAUDALIMETRO

Tav.7

Tav. 7

TAV.7: 1107601

KIT FLUSSIMETRO - KIT FLUXMETRE - KIT FLOW METER

KIT DURCHFLUSSMESSER - KIT CAUDALIMETRO

Rif. Cod. I F GB D E NOTE

12223280 DADO ECROU NUT MUTTER TUERCA M6Z

22224530 RONDELLA RONDELLE WASHER ANTERLEGSCHEIBE ARANDELA M6X12Z S1.6

33223613 PORTAGOMMA PORTE-CAOU-

TCHOUC HOSE FITTING SCHLAUCHHALTER ADAPTADOR M 1/2" D.13

43223633 FLUSSIMETRO FLUXMETRE FLOWMETER DURCHFLUSSMES-

SER CAUDALIMETRO 1/2” 150-1000 L/h

53223638 FASCETTA AD ANELLO

COLLIER EN FORME

DE

BAGUE

RING CLIP RINGSCHELLE ABRAZADERA DE

ANILLO D. 20-23

63223697 GUARNIZIONE ATTACCO

RAPIDO

JOINT DE RACCORD

EXCENTRIQUE

QUICK COUPLING

GASKET

DICHTUNG

SCHNELLKUPPLER

JUNTA CONEXIÓN

RÁPIDA

73224203 ATTACCO RAPIDO FIXATION RAPIDE QUICK CONNECTOR SCHNELLANSCHLUSS EMPALME RÁPIDO 1/2” M.

83224351 GOMITO 90° COUDE 90° 90° ELBOW FITTING 90°-KURVE CODO 90° 1/2” M.F.

93224580 PORTAGOMMA PORTE-CAOU-

TCHOUC HOSE FITTING SCHLAUCHHALTER ADAPTADOR 90° 1/2"F. D13

10 3227431 COLLARE ZINCATO COLLIER CLIP SCHELLE ABRAZADERA M6 DI 35 H61

11 3230844 SUPPORTO FLUSSIMETRO SUPPORT FLUXME-

TRE

SUPPORT FLOWME-

TER MOUNT FLOWMETER SOPORTE CAUDALI-

METRO 1/2” 150-1000 L/h

12 3230849 TUBO AIR WATER TUYAU EAU WATER HOSE WASSERSCHLAUCH TUBO DE AGUA 13 BAR 13X20

L.860

Other manuals for SPIN 15

2

This manual suits for next models

1

Table of contents

Other IMER Mixer manuals

Popular Mixer manuals by other brands

Curtis Stone

Curtis Stone CSMS0010 instruction manual

Creative Kitchens

Creative Kitchens PM10 user manual

Wassermann Dental-Maschinen

Wassermann Dental-Maschinen SIDOMIX user manual

Bestron

Bestron AKM500HR instruction manual

Siemens

Siemens MR008 GB Series instruction manual

Univex

Univex Swing Ring SRM20 Specifications