IMT 5525 User manual

Printed on 21 June, 2007

Manual Part # 99903688

Model 5525-6025-6625 Parts &

Specifications

Manual Effective April 2005

Revision Date 20070621

IOWA MOLD TOOLING CO., INC.

PO Box 189

Garner, IA 50438

Tel: 641-923-3711 FAX: 641-923-2424

Website: http://www.imt.com

Copyright © 2007 Iowa Mold Tooling Co., Inc.

All rights reserved

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording or otherwise without the

prior written permission of Iowa Mold Tooling Co., Inc.

Iowa Mold Tooling Co., Inc. is an Oshkosh Truck Corporation Company.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

i

Contents

Revisions .................................................................................................................................................... iii

Introduction 5

Specifications 7

General Specifications ..................................................................................................................................8

System Specifications...................................................................................................................................9

Geometric Configuration, 5525-6025-6625................................................................................................11

Capacity Chart, 5525 ..................................................................................................................................12

Capacity Chart, 6025 ..................................................................................................................................13

Capacity Chart, 6625 ..................................................................................................................................14

Reduced Capacity Lift Charts.....................................................................................................................15

Stability Confirmation Process ...................................................................................................................16

Crane Reference 19

5525-6025-6625 Assemblies & Grease Zerk Locations .............................................................................20

Recommended Spare Parts List ..................................................................................................................21

Crane Installation........................................................................................................................................22

Hydraulic Installation .................................................................................................................................23

Crane Control..............................................................................................................................................24

Control Valve Hydraulic Layout & Torque Values....................................................................................25

Control Valve Troubleshooting Chart ........................................................................................................27

Parts 29

Parts Information ........................................................................................................................................30

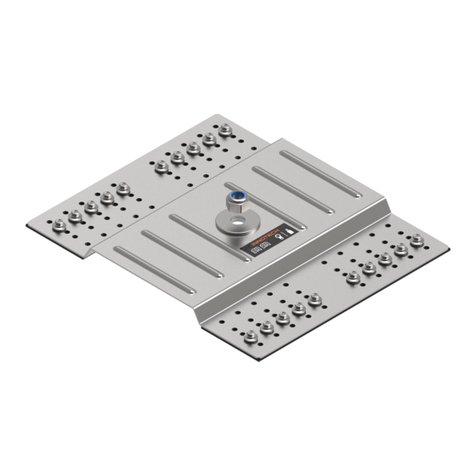

Primary and Alternate Base Configurations ...............................................................................................32

Base & Mast Assemblies ............................................................................................................................34

Base & Mast Assembly (99903692) (Primary configuration) .........................................................34

Base & Mast Assembly (99903694) (Alternate Configuration) ......................................................36

Gear Rotator (71056608) (Alternate configuration) ........................................................................38

Valve, Counterbalance (73540094) .................................................................................................40

Valve Body Assembly (51719127) (Primary Configuration)..........................................................41

Valve Body Assembly (51719469) (Alternate Configuration)........................................................42

Valvebank (73733947) ....................................................................................................................43

Gear Rotator (71056577).................................................................................................................45

Cylinder, Lower, 5525 (71411457) .................................................................................................47

Cylinder, Lower, 6025 (71410929) .................................................................................................49

Cylinder, Lower, 6625 (71411458) .................................................................................................51

Boom Assemblies & Cylinders...................................................................................................................53

Boom Assembly (99903756) (Eff. 12-20-06)..................................................................................53

Boom Assembly (99903624) (Through 12-19-05)..........................................................................57

Flip Sheave Assembly (99904248)..................................................................................................61

Crane Reach Retrofit Kits................................................................................................................63

Cylinder Assembly, Extension (71410928).....................................................................................64

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

ii Contents

Cord Reel Assembly (51713168) ....................................................................................................66

Crane & Winch Assemblies........................................................................................................................67

Crane & Winch Assembly (99903693) (Primary configuration).....................................................67

Crane & Winch Assembly (99903695) (Alternate configuration)...................................................70

Winch (70570761) (Used through 4-15-05) ....................................................................................72

Winch Drum Weldment (52719305) (Used through 4-15-05) ........................................................74

Winch Performance (70570771)......................................................................................................75

Winch Oil Specifications.................................................................................................................76

Hydraulic and Electrical System.................................................................................................................77

Hydraulic Installation, Primary Configuration (99903690).............................................................77

Hydraulic Installation, Alternate Configuration (99903699)...........................................................80

Electrical Harness, Radio Remote (77441131)................................................................................83

Electrical Schematic, Radio Remote (77441131)............................................................................84

Electrical Harness, Tethered Remote (77441164)...........................................................................85

Electrical Schematic, Tethered (77441164).....................................................................................85

Handle Assembly, Tethered Remote w/Engine Start (51719470)...................................................86

Controls ......................................................................................................................................................88

Controls Installation, Tethered (Kit 90719399/Dwg. 99903697) ....................................................88

Controls Installation / Radio Remote (Kit 90719400/Dwg. 99903697) ..........................................89

Auxiliary Outrigger Assemblies and Valvebanks.......................................................................................90

Outrigger, Power Out/Power Down, 7x5 (31712739) .....................................................................91

Outrigger, Manual Out/Power Down, 7x5 (31712740) ...................................................................93

Outrigger, Manual Out/Crank Down, 7x5 (31712741) ...................................................................95

Outrigger, Manual Out/Manual Down, 7x5 (31712902) .................................................................96

Cylinder, Power Down (3B205010) ................................................................................................97

Cylinder, Power Out (71411797) (Used 9-05 to 1-07) ....................................................................98

Cylinder, Power Out (3B142860) (Effective 2-07, prior to 8-05) .................................................100

Valve Bank, 2-Section (51714813) ...............................................................................................101

Valve Bank, 3-Section (51714812) ...............................................................................................102

Miscellaneous ...........................................................................................................................................103

Installation Kit (93719174) ...........................................................................................................103

Decal Kits & Installation (99903698)............................................................................................104

Boom Support, Adjustable, 3820-5020-5525-6025 (51718848) ...................................................107

Chassis Wiring Harness (99903340) .............................................................................................108

General Reference 109

Inspection Checklist..................................................................................................................................110

Deficiency / Recommendation / Corrective Action Report ......................................................................114

Wire Rope Inspection & Replacement......................................................................................................116

Hook Inspection........................................................................................................................................117

Holding Valve Inspection .........................................................................................................................118

Anti-Two-Block Device Inspection..........................................................................................................118

Thread Torques.........................................................................................................................................119

Turntable Bearing Thread Tightening Sequence ......................................................................................122

Turntable Bearing Inspection for Replacement ........................................................................................123

Turntable Bearing Tilt Test.......................................................................................................................123

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Contents iii

Revisions

DATE LOCATION DESCRIPTION

20050427 77441131, ECN 9771 - HARNESS, CHANGED HOUR METER & E-

STOP CONNECTION POINTS

77441164 ECN 9773 - ADDED CRANE HOUR METER CONNECTION

TO HARNESS

99903694, 99903695,

99903699, 51719469

ECN 9747 - ADDED COMPONENT ASSEMBLIES FOR

ALTERNATE BASE CONFIGURATION

20050512 77441164 ECN 9789 - UPDATE TO CP-700

99903690, 99903699 ECN 9796 - UPDATED HOSE KIT IN HYDRAULIC

INSTALLATION DRAWINGS

99903692, 99903624,

99903693-5, 99903697-8

ECN 9784 - UPDATES PER BOM AUDIT

73733947 ECN 9759 - CHANGE TO VALVEBANK ASM

20050726 77441131 ECN 9837 - CHANGE WIRING ON CP-1200

99903624, 99903693,

99903695

ECN 9862 - HARDWARE KIT UPDATES

20050922 99903692 ECN 9898 - CHANGE FROM 73051919 MOTOR TO

73511070 MOTOR.

20051012 31712739 ECN 9805 - CYLINDER 3B142860 REPLACED BY

71411797. ADDED SPARE PARTS LISTS TO

CYLINDERS.

20051115 99903624 ECN 9934 - BOOM PINS AND SHEAVE MOVED TO

SUBASSEMBLY

20051205 99903699, 99903690 ECN 9927-1 - CORRECTED VALVE FUNCTION

DIRECTIONS

71056608 ADDED SPARE PARTS FOR GEARBOX ASSEMBLY

20060111 CYLINDERS, VALVEBANK ECN 9836 -ADDED SPARE PARTS INFORMATION

20060330 99903756 ECN 9892 - CAST WINCH MOUNT

20060712 51718848 ECN 10156 - CHANGE TO HARDWARE KIT

20070516 99904248 ECN 10454 - ADDED FLIP SHEAVE DRAWING.

ECN 10438 - ADDED CRANE REACH RETROFIT KITS.

20070621 71410928 ECN 10514 – SHORTENED STROKE 6”.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

5

This volume deals with information applicable to your particular crane. For operating,

maintenance and repair instructions, refer to Telescopic Crane Volume 1: OPERATION,

MAINTENANCE AND REPAIR. (IMT part number 99903514.)

We recommend that this volume be kept in a safe place in the office.

This manual is provided to assist you with ordering parts for your IMT crane. It also contains

additional instructions regarding your particular installation.

It is the user’s responsibility to maintain and operate this unit in a manner that will result in the

safest working conditions possible.

Warranty of this unit will be void on any part of the unit subjected to misuse due to overloading,

abuse, lack of maintenance and unauthorized modifications. No warranty - verbal, written or

implied - other than the official, published IMT new machinery and equipment warranty will be

valid with this unit. In addition, it is also the user’s responsibility to be aware of existing Federal,

State and Local codes and regulations governing the safe use and maintenance of this unit. This

crane was designed and built to meet the standards of ANSI/ASME B30.5, Mobile & Locomotive

Cranes. Contact the American Society of Mechanical Engineers (www.asme.org) for more

information.

Throughout this manual, three means are used to draw the attention of personnel. They are

NOTEs, CAUTIONs and WARNINGs and are defined as follows:

NOTE

A NOTE is used to either convey additional information or to provide further emphasis for a

previous point.

CAUTION

A CAUTION is used when there is the very strong possibility of damage to the equipment or

premature equipment failure.

WARNING

A WARNING is used when there is the potential for personal injury or death.

For a safe work environment, treat this equipment with respect and service it regularly.

CHAPTER 1

Introduction

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

7

In This Chapter

General Specifications ...............................................................7

System Specifications ................................................................9

Geometric Configuration, 5525-6025-6625 ................................11

Capacity Chart, 5525..................................................................12

Capacity Chart, 6025..................................................................13

Capacity Chart, 6625..................................................................14

Reduced Capacity Lift Charts.....................................................15

Stability Confirmation Process ...................................................16

CHAPTER 2

Specifications

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

8 Model 5525-6025-6625 Parts & Specifications Manual Part # 99903688

General Specifications

GENERAL SPECIFICATIONS

CRANE RATING Model 5525 - 55,000 ft-lb (7.6 tm)

Model 6025 - 60,000 ft-lb (8.3 tm)

Model 6625 - 66,000 ft-lb (9.1 tm)

HORIZONTAL REACH (From centerline of

rotation)

25'-4" (7.7 m)

HYDRAULIC EXTENSIONS (2) 78" & 78" (198.1 cm & 198.1 cm)

LIFTING HEIGHT (From base of crane) 26'-7" (8.1 m)

CRANE WEIGHT 2,350 lb (1,066 kg)

OUTRIGGER SPAN (Required option)

Crane Side (From centerline of chassis) 90" (228.6 cm)

Opposite Crane Side (From centerline of

chassis)

48" (121.0 cm)

CRANE STORAGE HEIGHT 40" (101.6 cm)

MOUNTING SPACE REQUIRED (Crane base) 20" x 21" (50.8 cm x 53.3 cm)

OPTIMUM PUMP CAPACITY 10 U.S gpm (37.9 l/min)

SYSTEM OPERATING PRESSURE 3,000 psi (206.8 bar)

CENTER OF GRAVITY

Horizontal from Centerline of Rotation 41" (104.1 cm)

Vertical from Bottom of Crane Base 22" (55.9 cm)

TIE-DOWN BOLT PATTERN (8 bolts) 14-3/4" x 14-3/4" (37.5 cm x 37.5 cm)

ROTATIONAL TORQUE 9,000 ft-lb (1.2 tm)

* Crane rating (ft-lb) is the rated load (lb) multiplied by the respective distance (ft) from centerline of

rotation with all extensions retracted and lower boom in horizontal position.

PERFORMANCE CHARACTERISTICS

SPECIFICATIONS SPEED

ROTATION 400° (7.0 rad.) 33 seconds

LOWER BOOM ELEVATION -5° to +78° (-0.09 to +1.31 rad) 11 seconds to raise

13 seconds to lower

EXTENSION CYLINDERS

(2)

78" & 78" (198.1 cm & 198.1

cm)

23 seconds to extend

32 seconds to retract

PLANETARY GEAR LINE

SPEED

55 feet per minute (2nd wrap)

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 9

System Specifications

POWER SOURCE

PTO DRIVEN - Integral mounted hydraulic pump and PTO application. Other standard power

sources may be used. Minimum power required is 23.5 horsepower based on 10 GPM (37.9

liters/min) at 3,000 PSI (207 bar).

CYLINDER HOLDING VALVES

The base ends (extend sides) of the lower boom and extension cylinders are equipped with

integral-mounted counterbalance valves to prevent sudden cylinder collapse in case of hose or

other hydraulic failure. The extend side of the lower boom cylinder is equipped with a 10 gpm

counterbalance valve. The counterbalance valve serves several functions; first, it is a holding

valve. Secondly, it is designed to control the speed at which the lowering function operates and

allows that motion to be metered under load. Finally, it prevents the loss of an excess amount of

oil in the event of a hose failure. Only the oil in the hose at the time of the failure will be lost.

ROTATION SYSTEM

Turntable bearing with external tooth worm gear powered with a high-torque hydraulic motor.

Standard rotation is 420º.

HYDRAULIC SYSTEM (PTO DRIVEN)

The hydraulic system is an open-centered, full-pressure system that requires 10 GPM (37.85

liters/min.) optimum oil flow at 3000 psi (207 bar). It is equipped with a four-section, stack-type,

electric, remote control valve. The system includes a separate hydraulic oil reservoir, suction

line filter, and return-line filter.

EXCESSIVE LOAD LIMIT SYSTEM (ELLS)

Overloading of the crane is limited by the ELLS system. The system consists of a pressure

switch which is mounted on the extend side of the lower boom cylinder and connected

electrically to the lift side of the winch, the extend side of the extension boom, and the down side

of the lower boom. If the operator attempts to lift a load exceeding the rated capacity of the

crane, the winch lift, extension out and lower boom down functions will not operate. To relieve

the situation, the operator may set the load down (winch down) or retract the extension boom

(extension in).

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

10 Model 5525-6025-6625 Parts & Specifications Manual Part # 99903688

WINCH

The 5,500 lb planetary winch is powered using a high-torque hydraulic motor. The lifting

capacity of the winch is 5,500 lb (2,495 kg) one-part line. Maximum two-part line winch capacity

is 10,500 lb (4,762 kg). The winch is equipped with 100 ft (30.5 m) of 7/16" (1.1 cm) 6x25 FW

PRF RRL IWRC XIPS wire rope. A compact, anti-two block device is included to prevent the

lower block or hook assembly from coming in contact with the boom sheave assembly. The

winch meets ANSI B30.5 standards.

MINIMUM CHASSIS SPECIFICATIONS

CHASSIS STYLE Conventional Cab

WHEELBASE 154" (391 cm)

CAB-TO-AXLE 84" (213 cm)

RESISTANCE TO BENDING

MOMENT

800,000 in-lb (9,217 kg-m)

FRAME SECTION MODULUS 16 cubic inches (262.2 cc)

FRAME YIELD STRENGTH 50,000 psi (3,447 bar)

FRONT AXLE RATING (GAWR) 9,000 lb (4,082 kg)

REAR AXLE RATING (GAWR) 17,000 lb (7,711 kg)

GROSS VEHICLE RATING 26,000 lb (11,793 kg)

TRANSMISSION 5 speed

In addition to these specifications, heavy duty electrical and cooling systems are required. It is

recommended that the vehicle be equipped with an engine tachometer, auxiliary brake lock, and

power steering.

NOTES:

1 GAWR means Gross Axle Weight Rating. GAWR is dependent on all vehicle components

including axles, tires, wheels, springs, brakes, steering and frame strength meeting the

manufacturer's recommendations. Always specify GAWR when purchasing a truck.

2 Minimum axle requirements may increase with use of diesel engines, longer wheelbase or

service bodies. Contact the factory for more information.

3 Weight distribution calculations are required to determine final axle loading.

All chassis, crane and body combinations must be stability-tested to ensure stability per ANSI

B30.5

Iowa Mold Tooling Co., Inc. reserves the right to change specifications and design without notice.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 11

Geometric Configuration, 5525-6025-6625

6'-10"

(2.08 cm)

5'-2"

(1.58 m)

3'-6"

(1.07 m)

26'-7"

(8.11 m)

20'-4"

(6.20 m)

14'

(4.27 m)

3'-4"

(1.02 m) 1'-10" (55.9 cm)

1'-4"

(40.6 cm) 12'-4"

(3.76 m) 25'-4"

(7.72 m)

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

12 Model 5525-6025-6625 Parts & Specifications Manual Part # 99903688

Capacity Chart, 5525

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711 FAX: 641-923-2424 70396149

• Values in the box indicate the use of 2-

part line is required..

The weight of load-handling devices is part

of the load lifted and must be deducted from

the rated capacity. xxxx lb

xxxx kg

78°

60°

45°

30°

15°

0°

10500

4760 7760

3520

6290

2850

5515

2500

4990

2260

4460

2020

6940

3150

3635

1650

2815

1280

2400

1090

2100

950

1840

830

9500

4310 4930

2240

3870

1755

3330

1510

2960

1340

2600

1180

12'-4"

(3.75 m)

18'-10"

(5.75 m)

25'-4"

(7.72 m)

• Maximum 1-part line weight is 5500 lb

(2500 kg).

• See reduced capacity chart for

additional information when applicable.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 13

Capacity Chart, 6025

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711 FAX: 641-923-2424 70396096

• Values in the box indicate the use of 2-

part line is required..

The weight of load-handling devices is part

of the load lifted and must be deducted from

the rated capacity. xxxx lb

xxxx kg

78°

60°

45°

30°

15°

0°

10500

4760 8410

3820

6720

2880

5540

2510

5000

2270

4870

2210

7690

3490

3980

2000

3090

1400

2650

1200

2350

1070

2070

940

10500

4760 5460

2480

4270

1940

3660

1660

3260

1480

2880

1310

12'-4"

(3.75 m)

18'-10"

(5.75 m)

25'-4"

(7.72 m)

• Maximum 1-part line weight is 5500 lb

(2500 kg).

• See reduced capacity chart for

additional information when applicable.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

14 Model 5525-6025-6625 Parts & Specifications Manual Part # 99903688

Capacity Chart, 6625

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711 FAX: 641-923-2424 70396054

6625 HYDRAULIC CAPACITY CHART

• Values in the box indicate the use of 2-

part line is required..

The weight of load-handling devices is part

of the load lifted and must be deducted from

the rated capacity. xxxx lb

xxxx kg

78°

60°

45°

30°

15°

0°

10500

4760 9300

4220

7400

3360

6100

2770

5500

2495

5350

2430

7880

3575

4225

2010

3450

1570

2975

1350

2620

1190

2325

1055

10500

4760 5975

2710

4750

2155

4000

1815

3600

1630

3250

1475

12'-4"

(3.75 m)

18'-10"

(5.75 m)

25'-4"

(7.72 m)

• Maximum 1-part line weight is 5500 lb

(2500 kg).

• See reduced capacity chart for

additional information when applicable.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 15

Reduced Capacity Lift Charts

The Reduced Capacity Lift Chart system was conceived to inform the end user of the allowable

loads which can be lifted off the sides of a mechanics truck. IMT devised a color-coded chart

defining the sectors where less than hydraulic crane capacity can be lifted. The color-coded

chart (Reduced Capacity Lift Chart or RCLC) corresponds to a visual indicator on the base of the

crane. The RCLC displays the percentage of the hydraulic crane capacity to be lifted in each

sector. The visual indicator on the crane base gives the operator a reference of the sectors. With

this information the end user can more safely use the mechanics truck. Stability confirmation

yields data to produce a Reduced Capacity Lift Chart if necessary. Some units may not require

de-rating over the sides, but a majority will.

If the IMT crane is installed by an IMT distributor, the distributor is responsible for stability

confirmation. IMT supplies a generic RCLC decal for dealer installation.

CAUTION

CHASSIS WEIGHT, SUSPENSION, AND UNIT SET UP, INCLUDING NUMBER AND TYPE

OF OUTRIGGERS, LIFTING SURFACE, ETC., HAVE A SIGNIFICANT IMPACT ON

STABILITY.

The basic illustration shows full crane capacity off the rear of the truck and reduced capacity

when lifting over the sides. Lifting over the front of the truck is not permitted.

For an IMT 5525 crane with a standard IMT Dominator® II body, the derated percentage is 80%

in the yellow quandrants. For an IMT 6025 crane with a standard Dominator II body, the derated

percentage is 70% in the yellow quadrants.

100% OF CAPACITY

CHART PERMITTED

(INCLUDES TRUCK

BED AREA)

FILL IN %

CAPACITY

CHART

PERMITTED

FILL IN %

CAPACITY

CHART

PERMITTED

LIFTING NOT

PERMITTED IN

THIS AREA

CAB

TRUCK

BED

60 °

90 °

120 °

Red Zone

Yello

w

Zone

Y

ellow

Z

one

Green Zone

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

16 Model 5525-6025-6625 Parts & Specifications Manual Part # 99903688

Stability Confirmation Process

To confirm stability,

1 Set up unit on a hard, flat surface which meets SAE J765 requirements. Use all

recommended equipment such as outriggers, etc.

2 Position the crane at full, horizontal reach. For a 5525 crane, use a 2,172 ± 10 lb test weight

suspended over the rear of the truck. For a 6025 crane, use a 2443 ± 10 lb test weight

suspended over the rear of the truck. Rotate the test weight up to the point where the pointer

on the crane base meets the yellow bands on both sides of the unit. If the unit keeps at least

one rear tire firmly touching the ground, the test can be continued for the capacity on the

sides. If the criterion is not met for the rear of the unit, a custom RCLC is required. Please

contact IMT for assistance in this situation.

NOTE

THE TIRE IS TOUCHING THE GROUND WHEN AT LEAST 90% OR MORE OF THE TREAD

SURFACE IS CONTACTING THE GROUND.

Once stability is verified over the rear section of the truck, test the stability on the sides of the

truck. Again, using the test weight in a fully extended, horizontal position, rotate the crane

around the sides of the truck. If the test weight passes the sides with at least one rear tire

firmly touching the ground, a standard Hydraulic Capacity Chart may be used rather than a

Reduced Capacity Lift Chart.

CAUTION

THE UNIT MAY TILT SEVERELY!

If the unit does not pass the side load test, you must begin retracting the booms to find the

usable percentage of the crane capacity.

For a 5525 crane, retract the booms 42” for a capacity derating to 80%. For a 6025 crane,

retract the booms 63” for a capacity derating to 70%. Measure from a fixed point on the

boom tip horizontally to a fixed point on the main boom to verify how far the booms have

been retracted. See table.

CRANE MODEL TEST WEIGHT PERCENT RATED

LOAD (%)

DISTANCE BOOMS ARE

RETRACTED FROM FULL

EXTENSION (INCHES)

5525 2,172 ± 10 lb 80% 42"

6025 2,443 ± 10 lb 70% 63"

Once the booms are retracted, re-check stability by again rotating the crane around the sides

of the truck, making sure the weight passes by the yellow region marked on the crane base

with at least one rear tire firmly touching the ground.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 17

Test both sides of the truck. If the crane cannot rotate through the yellow zone with at least

one rear tire firmly touching the ground, you must work with IMT for a custom Reduced

Capacity Lift Chart. In this situation, please contact IMT for assistance.

CAUTION

DO NOT LIFT IN THE “NO LIFTING ZONE.”

Follow safe crane practices throughout the testing. Keep the load as close to the ground as

possible.

The minimum 90° “No Lifting Zone” over the cab must be on ALL Reduced Capacity Load

Charts. The zone may need to be increased if front outriggers are not used. In addition, the

stability may be greater on one side of the unit than the other, but IMT has chosen to keep

both ratings the same. Thus, the lowest stability percentage is reported for each side.

Install the RCLC decal on the inside of the crane compartment door.

Keep a record of the reduced stability test to verify the decals in case replacement is

necessary.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Other manuals for 5525

2

This manual suits for next models

2

Table of contents

Other IMT Construction Equipment manuals