MANUAL • Subject to alteration! Stand: October 2021

ipf electronic gmbh

│

Rosmarter Allee 14 • 58762 Altena • Germany

│

Tel +49 2351 9365-0 • info@ipf-electronic.com •www.ipf-electronic.com 3

Cleaning

For cleaning a soft cloth moistened with soapy water is recommended.

Commissioning and setting

The measuring range is taught-in and the analog output is switched over by connecting the black wire (PIN 4) to the

operating voltage (PIN1).

The teach process is aborted after 20 seconds (Time Out function).

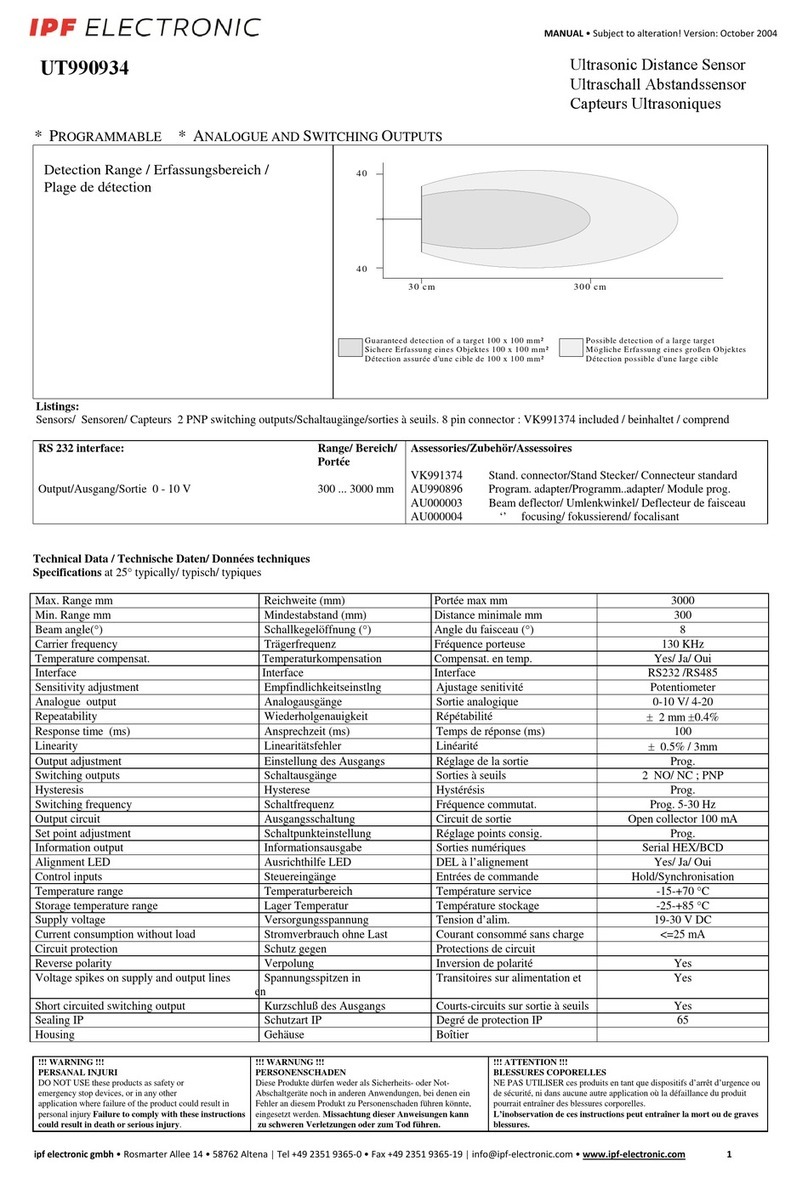

Make sure that the object to be detected is always within the scanning range limits (150 … 1500mm). The distance between

value 1 and value 2 must be at least 100mm.

1. Teach-in of the measuring range

1. Position the object at the point where the analog value should be 4mA or 0V.

2. Connect the black wire to the operating voltage for between 0.1 and 2 seconds. The LED is flashing with approx.

1Hz.

3. Position the object at the point where the analog value should be 20mA or 10V.

4. Connect the black wire to the operating voltage for between 0.1 and 2 seconds.

5. The analog output now operates within the defined measuring limits.

2. Changing the output function

1. Connect the black wire to the operating voltage for longer than 6 seconds.

2. The physical quantity of the analog output is changed (instead of current output 4 ... 20mA voltage output 0 ...

10V or vice versa).

Note: Be aware that a considerably larger load resistance is required for operation as a voltage output (see technical

data). It is therefore recommended to disconnect the analog output before each change of the output function to avoid

device damage

3. LED display after each teach process

If the status LED is flashing twice, the teach process was successful and the sensor is working with the new values.

If the status LED is flashing four times, the teach process has been aborted or the time window of 20 seconds has

been exceeded. The sensor operates with maximum measuring range.

On the following page the descriptions are shown again graphically.

The following additional settings can be made using the IO-Link interface:

Measuring ranges < 100mm

Function of the black wire (PIN 4): Teach-in of the analog output

Switching output (push-pull, PNP or NPN)

Synchronization (see "master-slave function" on page 4)

Multiplex (see "master-slave function" on page 4)

If "switching output" is activated, the switching mode, switching function and

hysteresis can also be set

Analog output: 0 ... 20mA, 4 ... 20mA, 0 ... 10V, disable

Teach switching points (the state of the switching output is always output via IO-Link)

Switch-on and switch-off delay for switching output

Restore factory settings